Garbage can with compaction function for green building

A technology of green building and trash can, applied in the direction of trash can, garbage collection, application, etc., can solve the problems of simple structure, occupying space and inconvenient use of trash can, and achieve the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

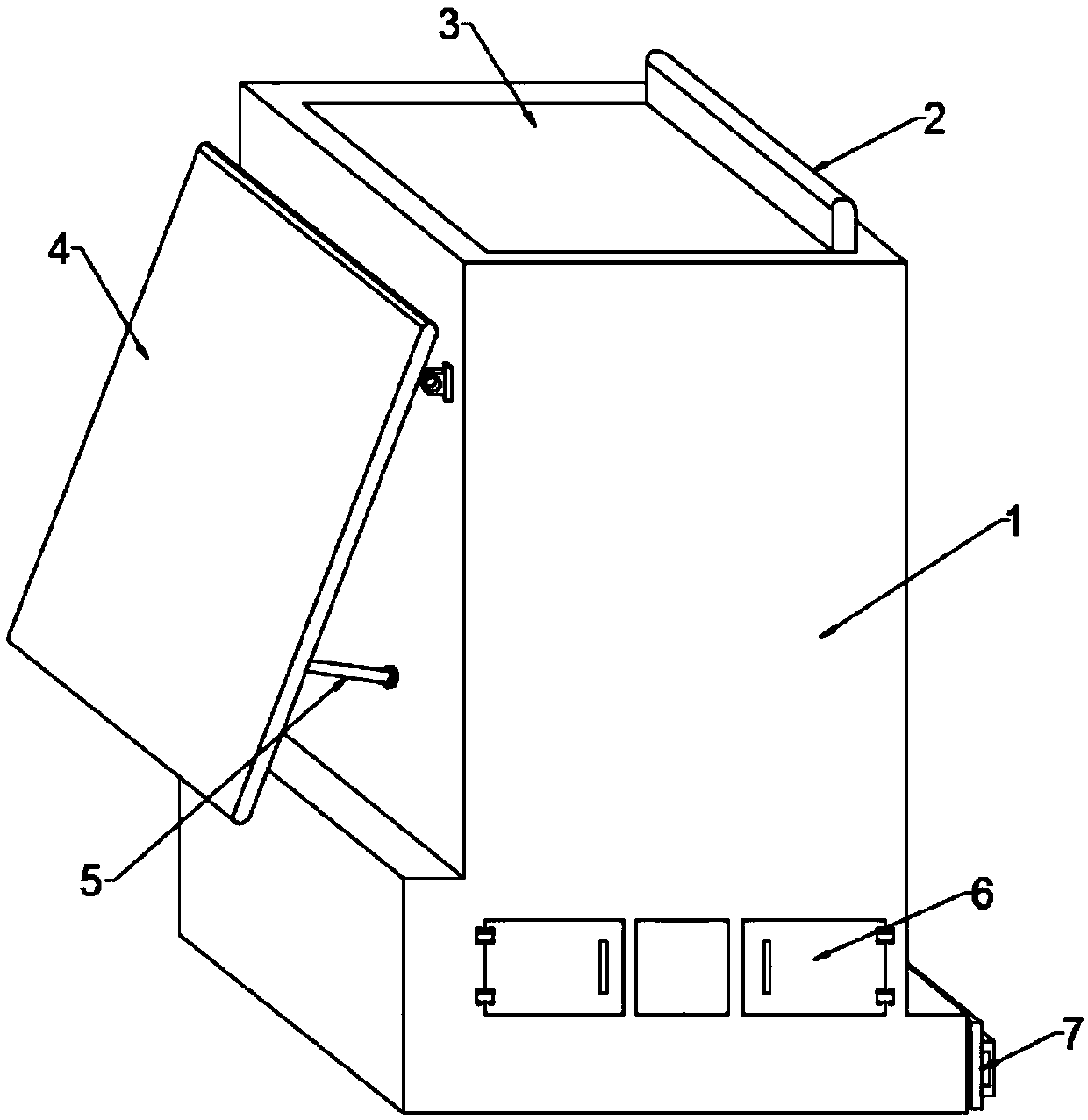

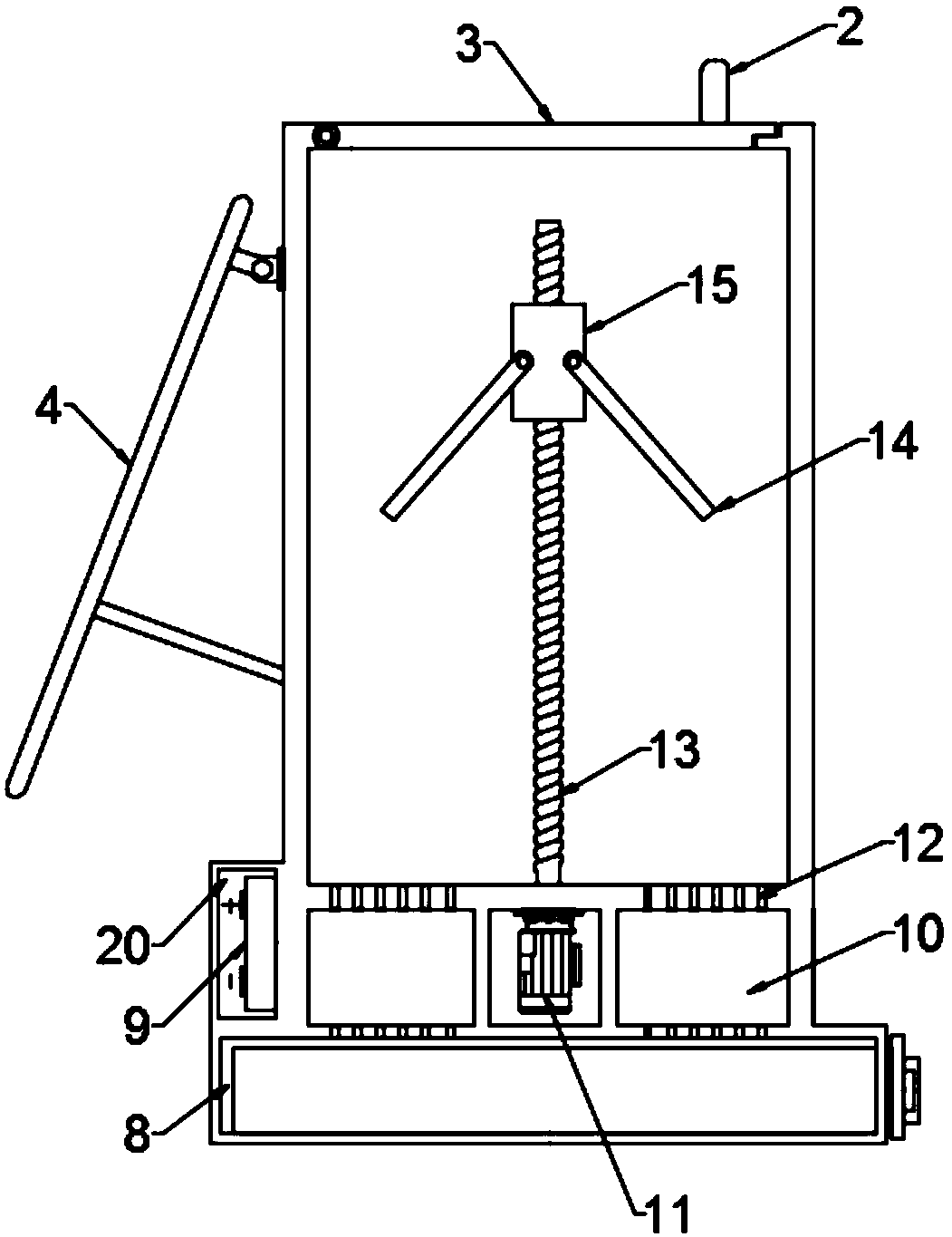

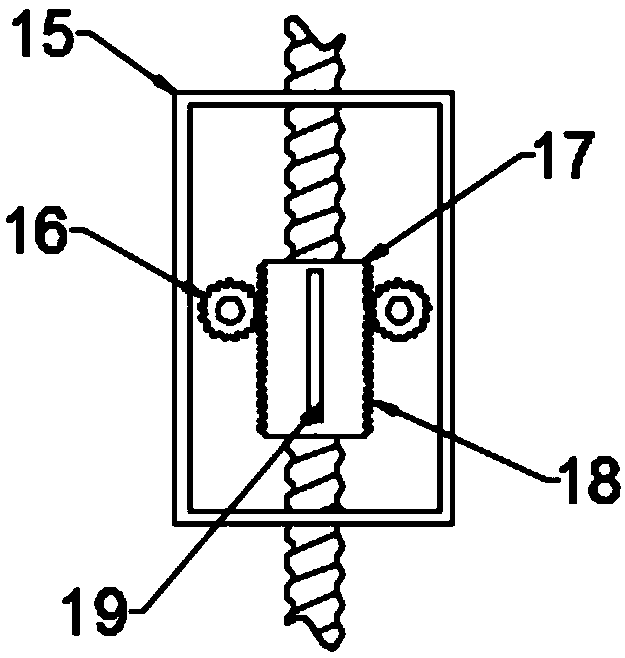

[0022] In the embodiment of the present invention, a garbage can with a compacting function for green buildings includes a garbage can body 1; 7, the collection tank placement cavity 8, and the collection tank placement cavity 8 communicates with the inside of the garbage can body 1 through the drain hole 12, and the sewage inside the garbage can body 1 enters the waste water collection tank 7 through the drainage hole 12 to collect, so The upper end of the trash can body 1 is hinged with an upper cover 3, and the upper cover 3 is fixed with a pull handle 2, so as to facilitate the opening of the upper cover 3. The inside of the trash can body 1 is provided with a motor 11, the motor 11 The output shaft is fixedly connected with the threaded rod 13 through a coupling, and the threaded rod 13 is sleeved with a transmission block 15. The inside of the transmission block 15 is a cavity structure, and the inner side of the transmission block 15 is slidingly connected with a threade...

Embodiment 2

[0028] The difference between the second embodiment and the first embodiment is that the side end of the garbage can body 1 is obliquely installed with a solar panel 4 through the support rod 5, and the solar panel 4 is electrically connected with the battery 9 placed in the battery storage cavity 20, and is connected by The solar panel 4 charges the storage battery 9 to save energy.

[0029] It should be noted that the motor in this application is an application of the prior art. The motor drives the threaded rod to rotate. When the threaded rod rotates, it drives the threaded sleeve to move. When the threaded sleeve moves downward, it will drive the pressure plate to rotate upward. When the pressure plate moves to In the horizontal state, the threaded sleeve no longer moves relative to the transmission block. At this time, it will drive the transmission block and the pressure plate to move downwards to realize the compaction of garbage. When the threaded sleeve moves upwards,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com