Upper limb shoulder exoskeleton based on screw transmission structure

A wire transmission and exoskeleton technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large motion deflection inertia, inoperability, worker fatigue, etc., to ensure motion performance, reduce structural thickness, and improve flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

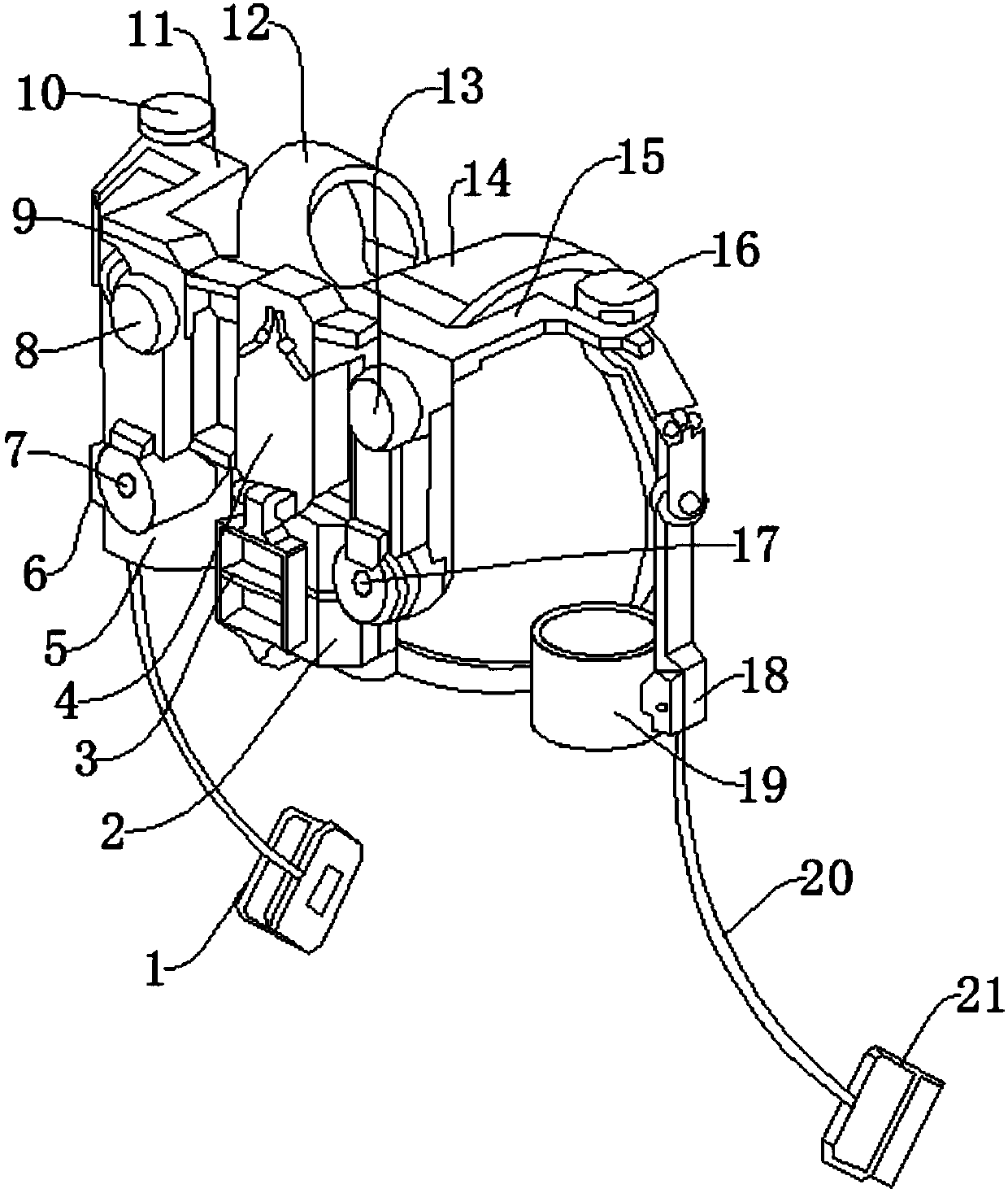

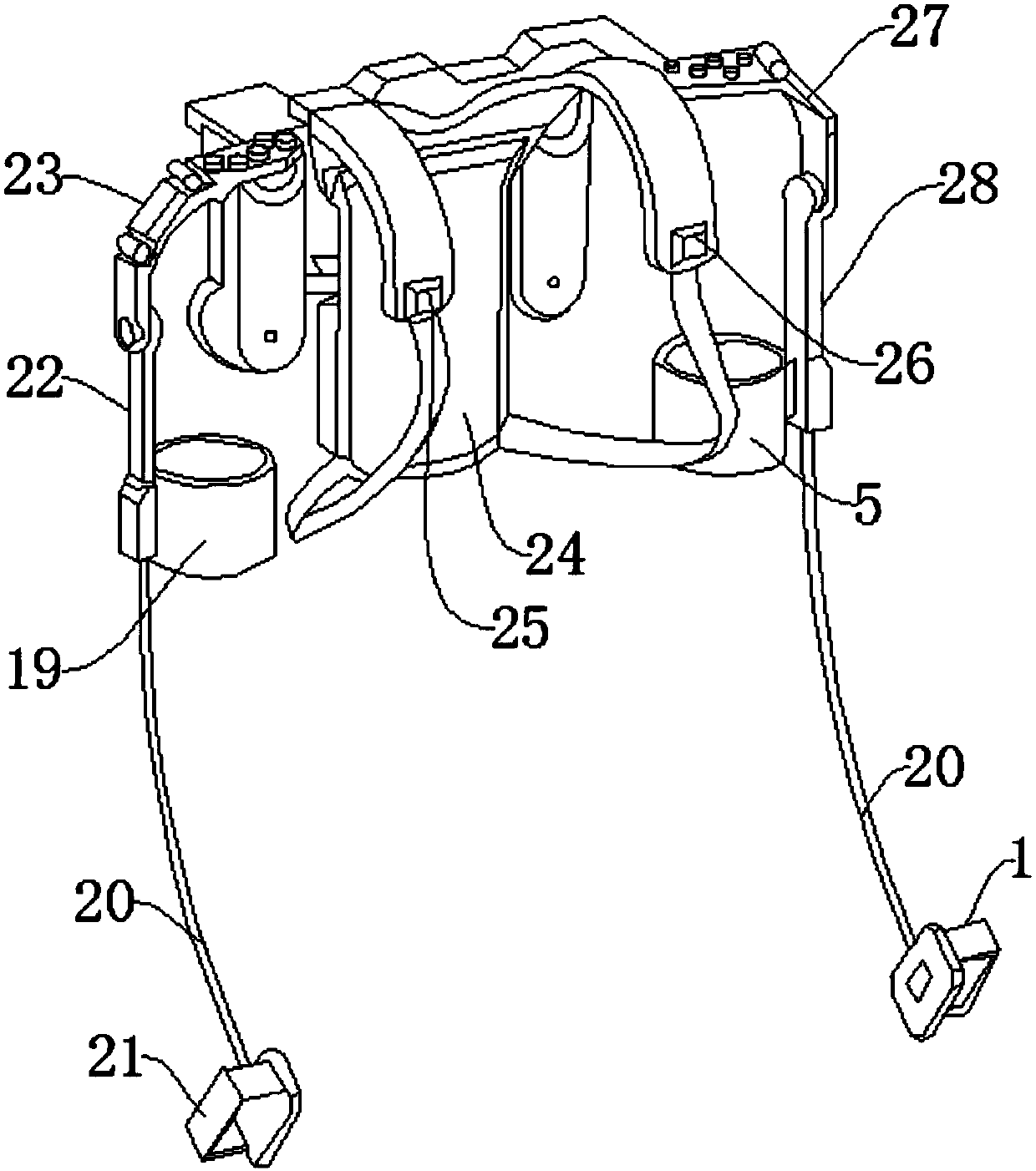

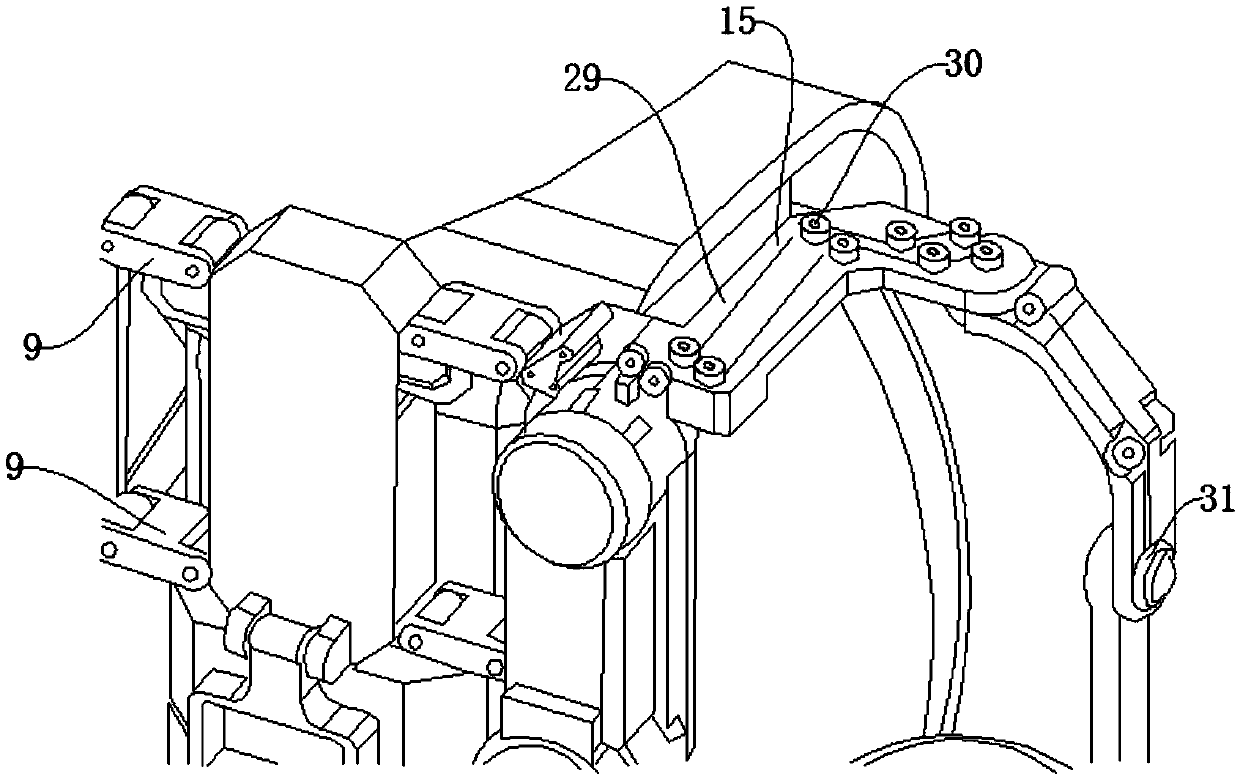

[0028] Such as Figure 1-Figure 5As shown, an upper limb shoulder exoskeleton based on a wire transmission structure includes a left hand effector 1, a cable 20 and a left upper arm force sensor 6, the upper side of the left hand effector 1 is provided with the cable 20, the cable 20 Information can be transmitted. The end of the cable 20 away from the left-hand effector 1 is provided with the left upper arm force sensor 6. The left upper arm force sensor 6 can measure the weight of the object being carried. The left upper arm force sensor 6 is provided with a left upper arm force sensor 6. The fixing ring 5, the left upper arm fixing ring 5 can fix the left upper arm, the upper side of the left upper arm fixing ring 5 is provided with a left upper arm steel member 28, and the upper side of the left upper arm steel member 28 is provided with a left steel wire steering membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com