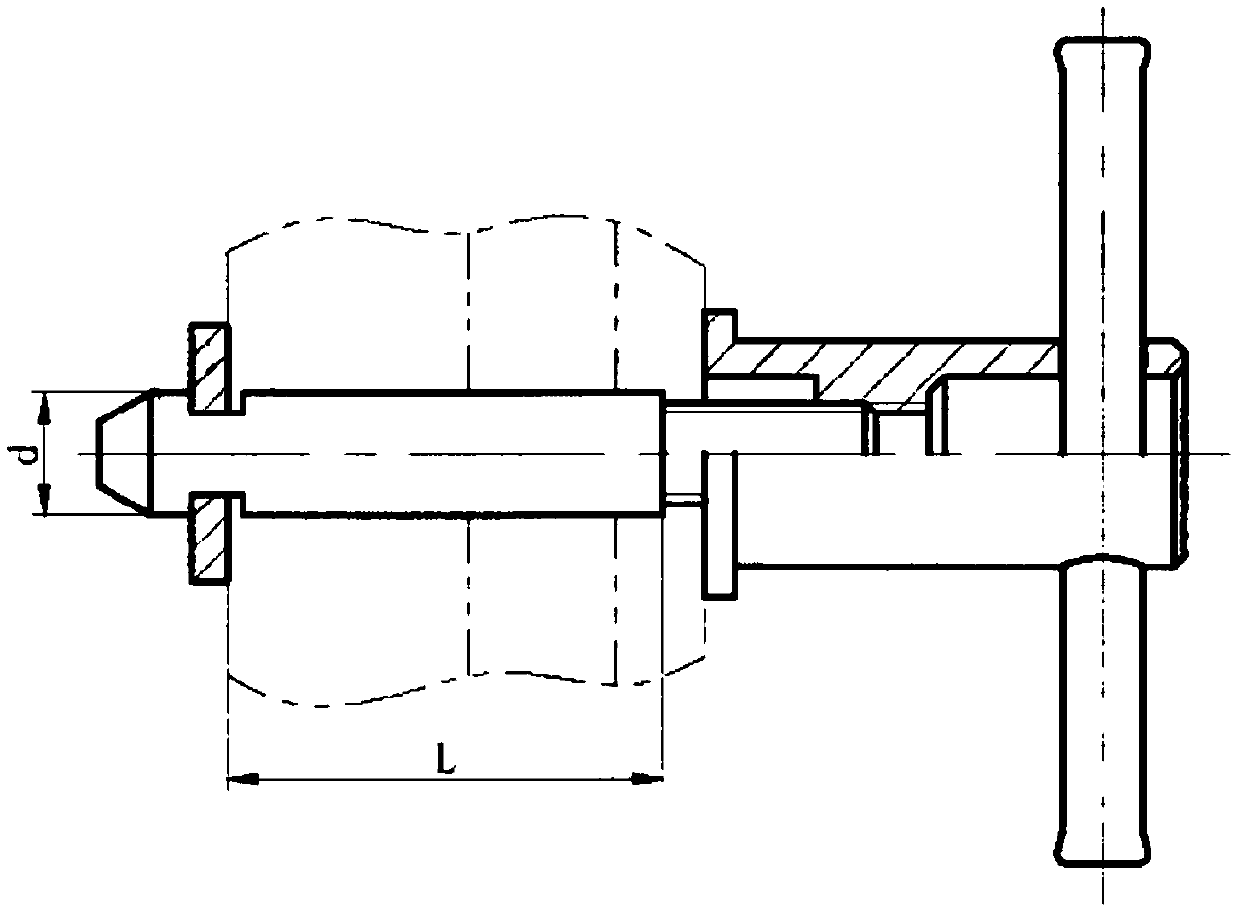

High-precision spiral positioning and clamping device

A positioning and clamping, high-precision technology, used in workpiece clamping devices, aircraft assembly, manufacturing tools, etc., can solve problems such as inappropriate clamping and positioning devices and inability to achieve clamping functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

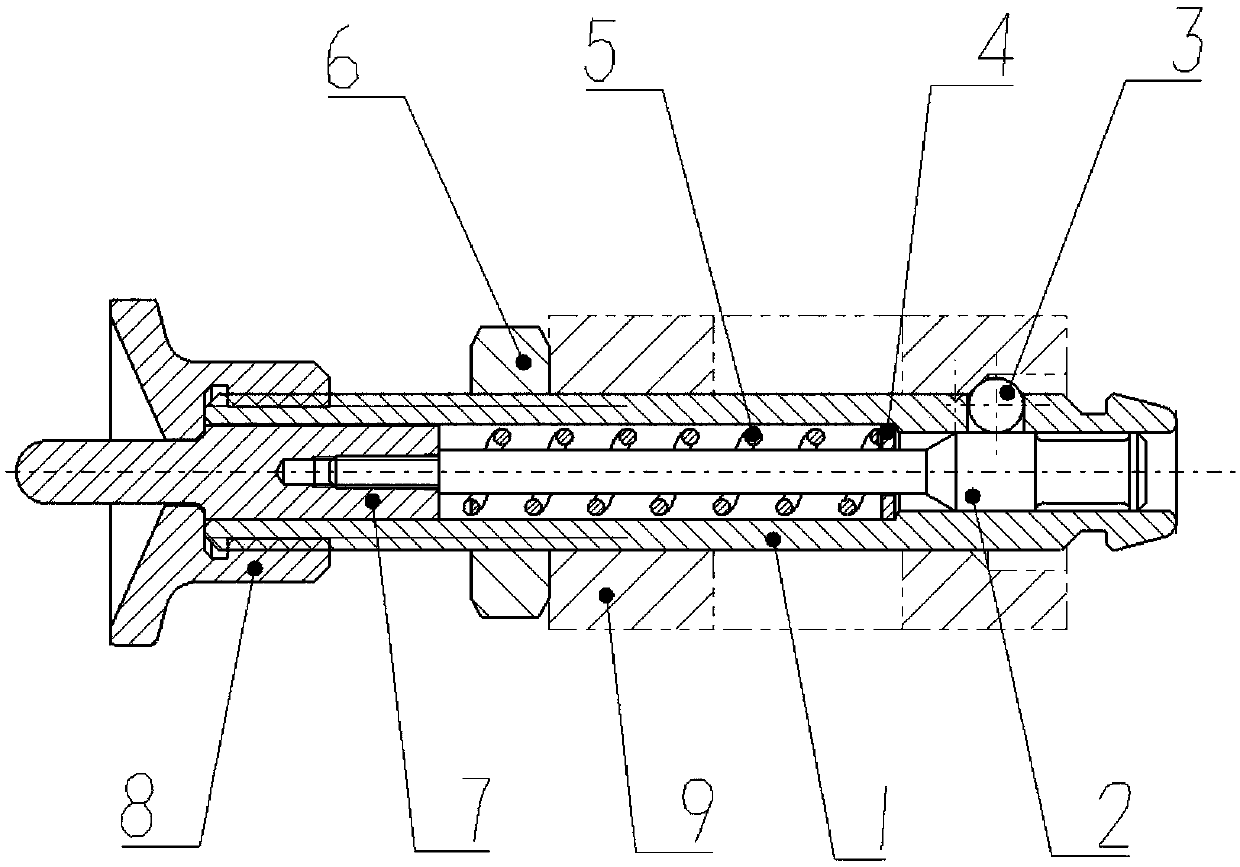

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0016] Such as figure 2 As shown, a high-precision screw positioning clamping device includes a threaded pin 1, a variable diameter mandrel 2, a steel ball 3, a washer 4, a spring 5, an outer hex nut 6, a pressure rod 7 and a handle 8;

[0017] The threaded pin 1 is a tubular structure, the front end is provided with a conical head for easy insertion into the hole, at least three radial holes are opened near the tapered head end, the radial holes are located on the same circumference, and steel balls 3 are installed in the holes; threaded pin 1 The middle part is used for the positioning of the body 9; the threaded pin 1 has an external thread at the rear, which is threadedly connected with the outer hex nut 6, and is used to compress the body 9; the end of the handle 8 is axially provided with a stepped through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com