Three-dimensional dynamic positioning system for mobile dual-plane X-ray system

A dynamic positioning and optical system technology, which is applied in the fields of radiological diagnosis instruments, medical science, diagnosis, etc., can solve problems such as calibration and positioning of dual X-ray fluoroscopic imaging systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The stereoscopic dynamic positioning system in this example includes a control device, a registration device, a single calibration device and a double calibration device; wherein the control device is used to control the first X-ray emitting device and the second X-ray emitting device to emit X-rays synchronously.

[0043] In a preferred solution, in order to prevent the X-rays emitted by the first X-ray emitting device and the second X-ray emitting device from producing optical interference, the control device controls the first X-ray emitting device and the second X-ray emitting device to emit X-rays asynchronously, such as The first X-ray emitting device is delayed by 0-10ms from the second X-ray emitting device.

[0044] The stereoscopic dynamic positioning system in this example is a three-level calibration realized by sequentially executing the registration device, single calibration device and double calibration device. Specifically, the execution of the registrat...

Embodiment 2

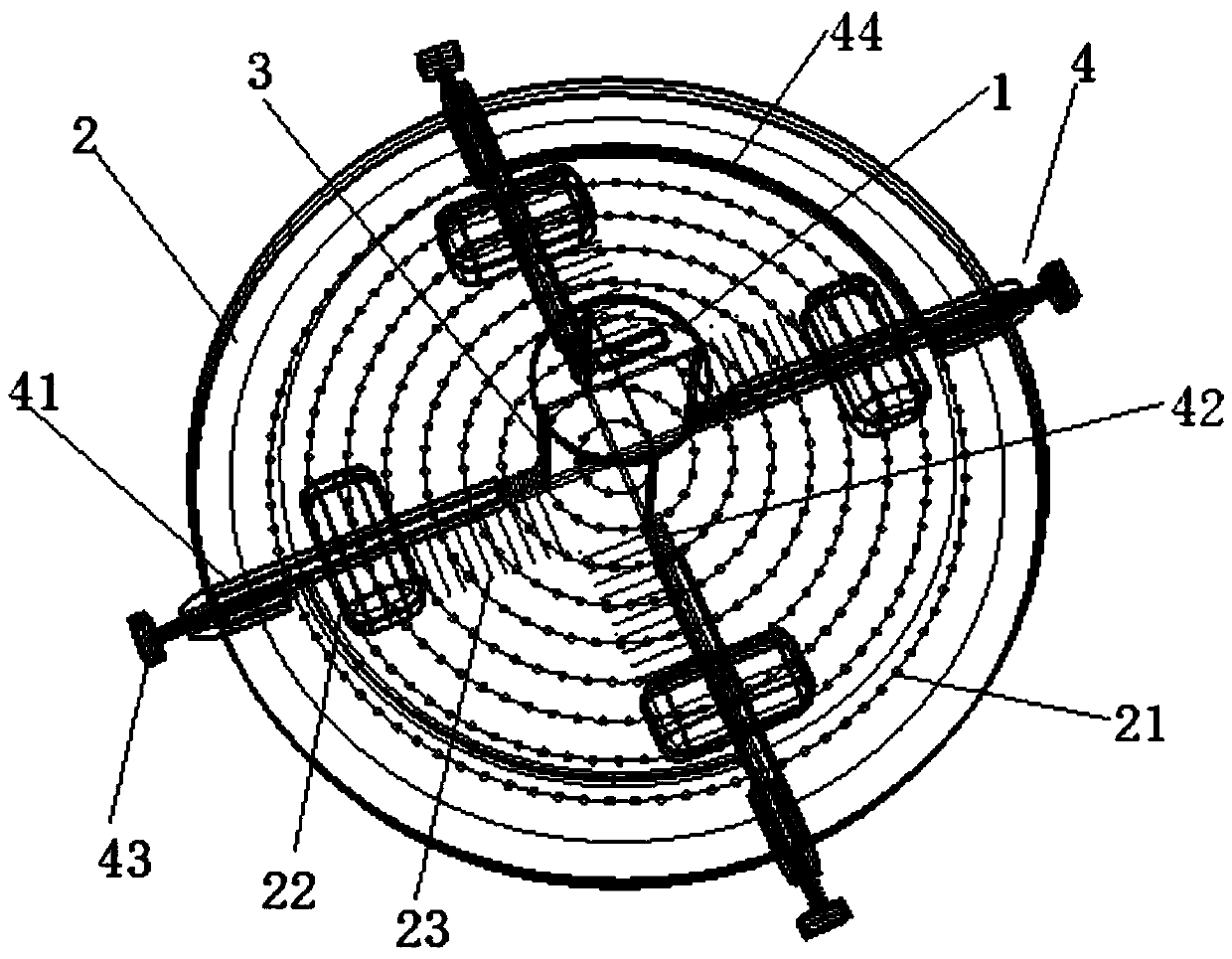

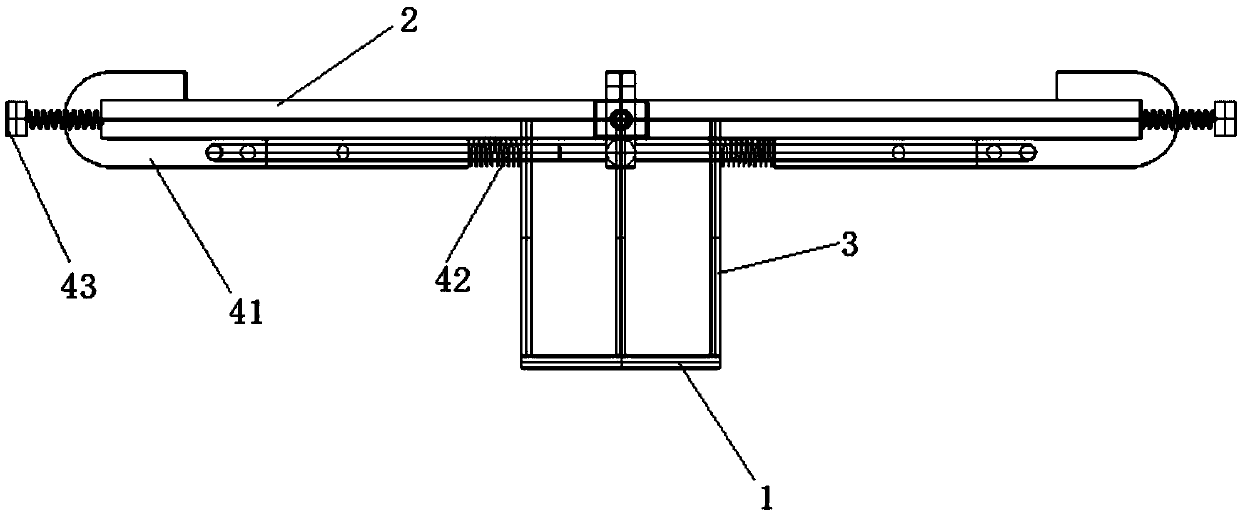

[0071] Based on Embodiment 1, this example describes in detail the structure of the single calibration device, as figure 1 , figure 2 and image 3As shown, the single calibration device includes a first circular plexiglass plate 1, a second circular plexiglass plate 2, several support columns 3 and an adjustment mechanism 4, wherein the symmetrical equipment around the center of the first circular plexiglass plate 1 has Some holes, the second circular plexiglass plate is also uniformly provided with some holes 21, and the arrangement of some holes 21 is light diffusion characteristics, and the two ends of some support columns 3 are respectively connected to the first circular plexiglass plate 1 And on the second circular plexiglass plate 2; the adjustment mechanism 4 is installed on the second circular plexiglass plate 2, when the single calibration device is installed on the first / second X-ray receiving device by the adjustment mechanism 4, the adjustment mechanism 4 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com