Weld seam detection device

A welding seam detection and detection component technology, which is applied in the direction of measuring devices, test metals, material inspection products, etc., can solve the problems of difficult production, high cost, and limited detection accuracy, and achieve reliable monitoring sampling points and convenient and fast measurement , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

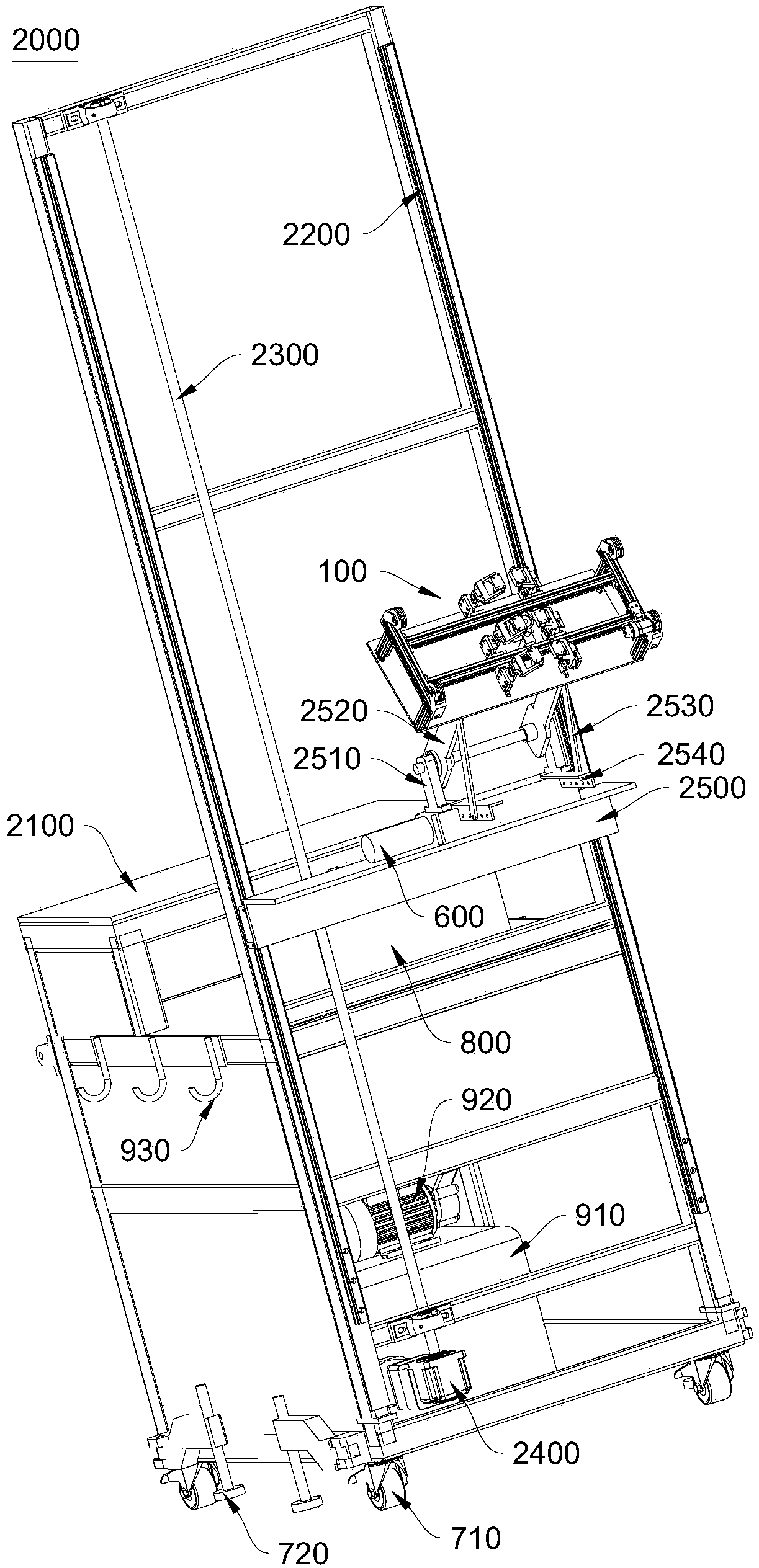

[0034] Please refer to Figures 1 to 2 , this embodiment provides a weld detection device 2000 . The welding seam detection device 2000 includes: a base 2100 , a guide rail 2200 , a lifting platform 2500 , a column 2510 , a first support rod 2520 , a second support rod 2530 , an adjustment rod 2540 and a welding seam detection end 1000 .

[0035]The guide rail 2200 is arranged perpendicular to the base 2100 , and the lifting platform 2500 is slidably matched to the guide rail 2200 . The base 2100 is further provided with a first lead screw 2300 parallel to the guide rail 2200 and a first power device 2400 for drivingly connecting with the first lead screw 2300 . .

[0036] The welding seam detection end 1000 includes a base plate 100, a support column 110, a beam 120, a connecting rod 130, a camera 200, a laser pointer 300 and a detection assembly, and the detection assembly includes two sets of detection heads. The detection head includes a sliding rail 410 , a sliding blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com