Capsule drying device

A technology of drying device and capsule, applied in the field of medicine, can solve problems such as poor effect, failure, deformation and loss of capsule, and achieve the effect of improving drying effect, simple structure and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

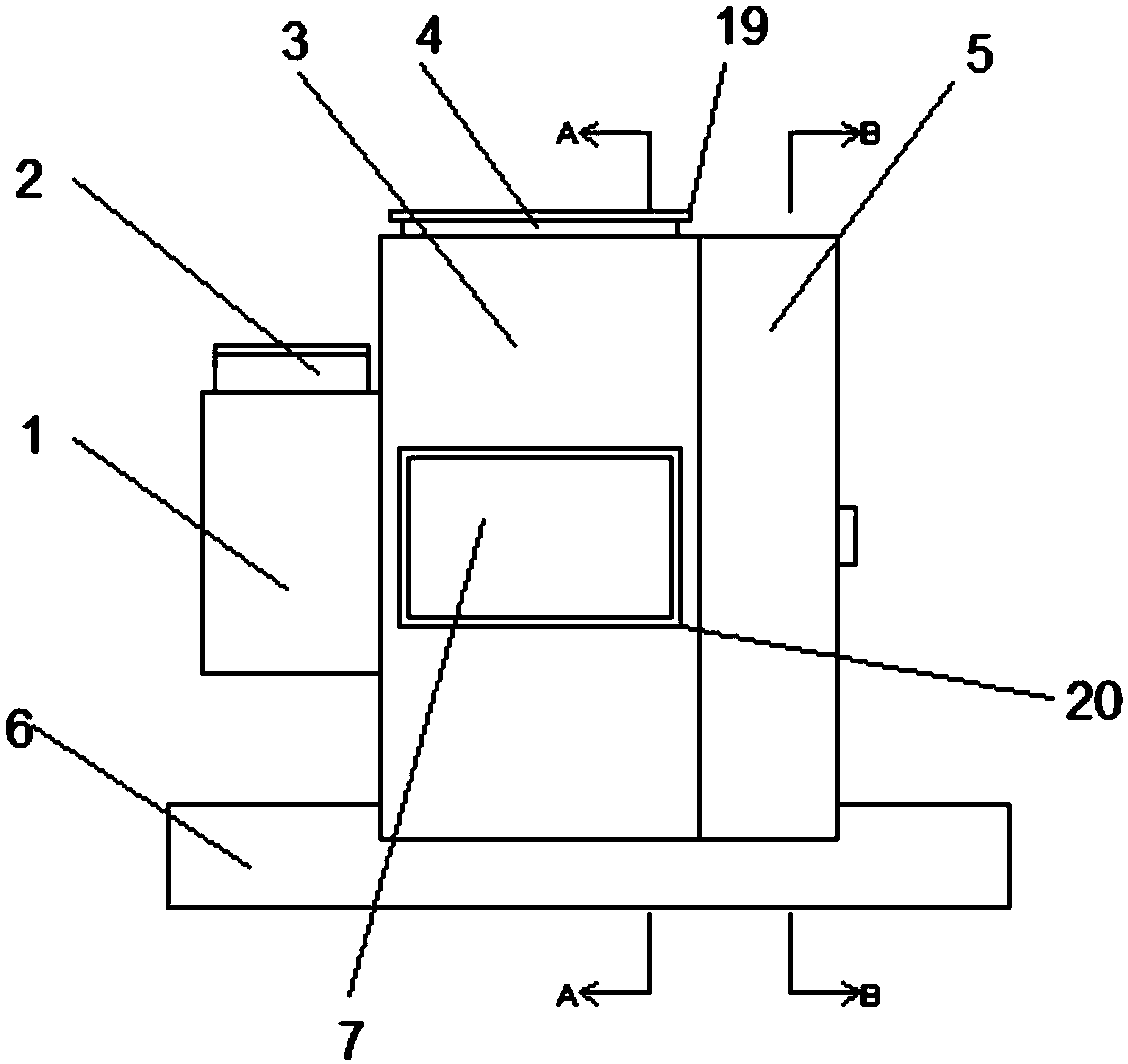

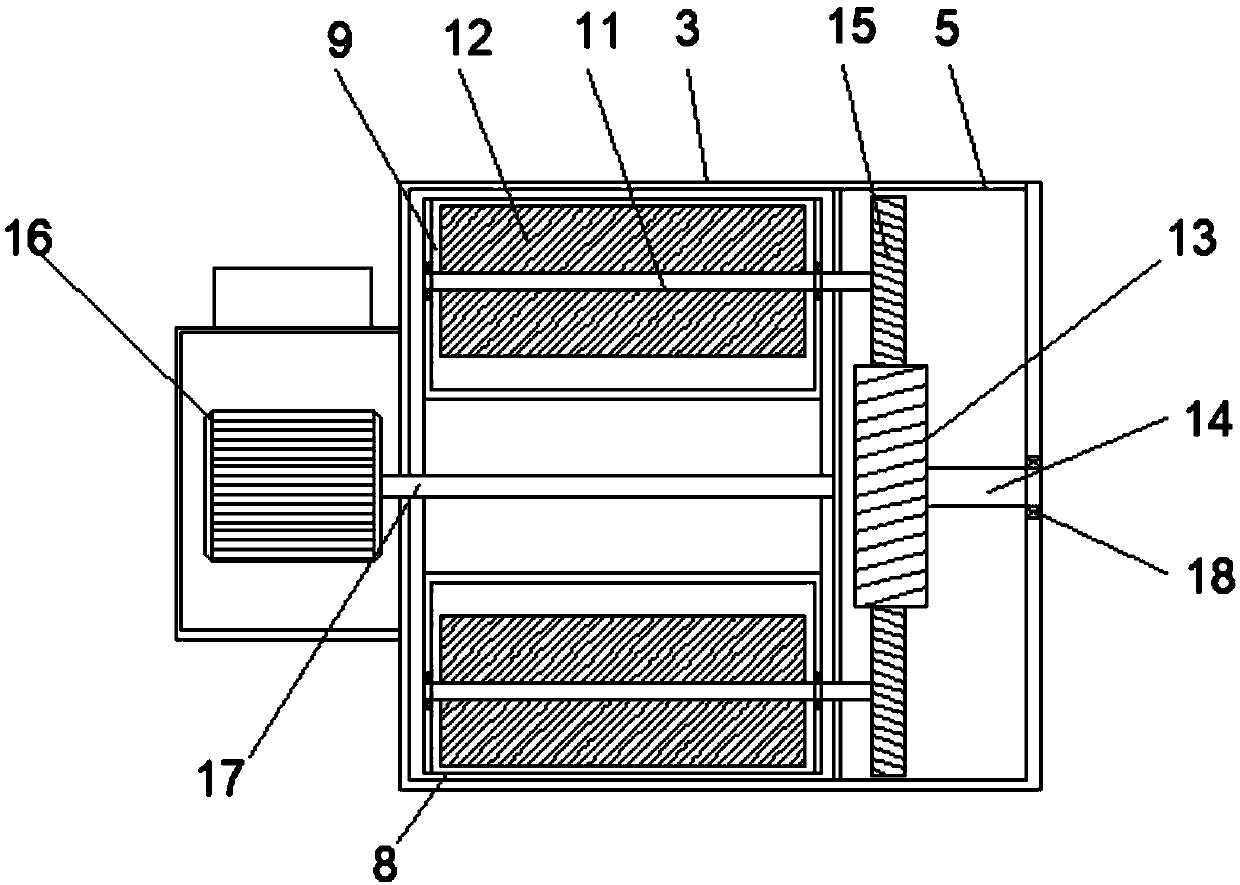

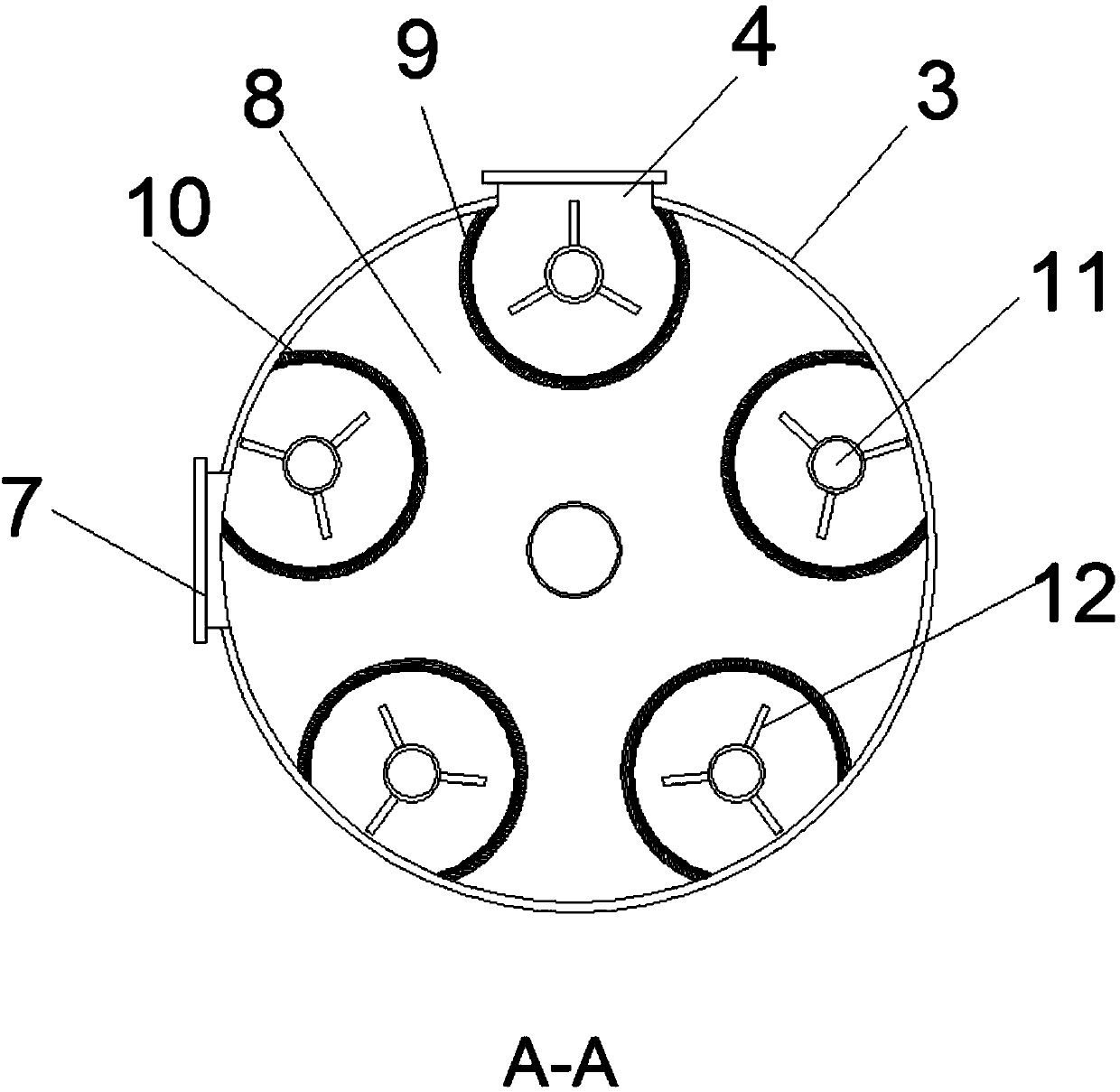

[0022] see Figure 1~4 , in an embodiment of the present invention, a capsule drying device includes a drying box 3, a drying cylinder 8 is arranged in the drying box 3, the drying cylinder 8 is a cylindrical cylinder body, and the outer wall of the drying cylinder 8 Close to the inner wall of the drying box 3, the drying cylinder 8 is provided with a number of drying grooves 9, the drying grooves 9 are smooth surface grooves sunken inwards and evenly distributed on the edge of the drying cylinder 8, and the drying A drying device is provided in the dry tank 9, a feed port 4 and a feed port 7 are provided on the drying box 3, and a rotating drive device for a drying drum 8 is provided at the left end of the drying box 3, and the drying box 3 A turning device is installed in the drying tank 9 of the cylinder 8. During specific work, the capsules to be dried are dropped into the drying tank 9 of the drying cylinder 8 through the feed port 4. The drying cylinder 8 is provided wit...

Embodiment 2

[0030] see Figure 1~4 , on the basis of Example 1, the embodiment of the present invention upgrades the function of a capsule drying device, specifically:

[0031] The upper end of the motor box 1 is provided with a control box 2, and the control box 2 is provided with a PLC controller electrically connected to the motor 16. The speed and running time of the motor effectively controlled by the controller are convenient for the automatic drying of capsules. conduct and adjust.

[0032] Preferably, the model of the PLC controller is Siemens S7-discharge port sealing cover 200CN.

[0033] It should be noted that the motor 16 in this application is an application of the prior art, and a drying box 3 is provided in this application, and a drying cylinder 8 is arranged inside the drying box 3, and the drying cylinder 8 is a cylindrical cylinder Body, the outer wall of the drying cylinder 8 is close to the inner wall of the drying box 3, the drying cylinder 8 is provided with a nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com