Magnetic liquid sealing device with heat conduction rods and heat dissipation sleeve

A magnetic liquid and sealing device technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inability to discharge heat in time, inconvenient production and practical use, and increase the structural complexity of the magnetic liquid sealing device. Fast heat dissipation effect, the effect of avoiding the deterioration of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

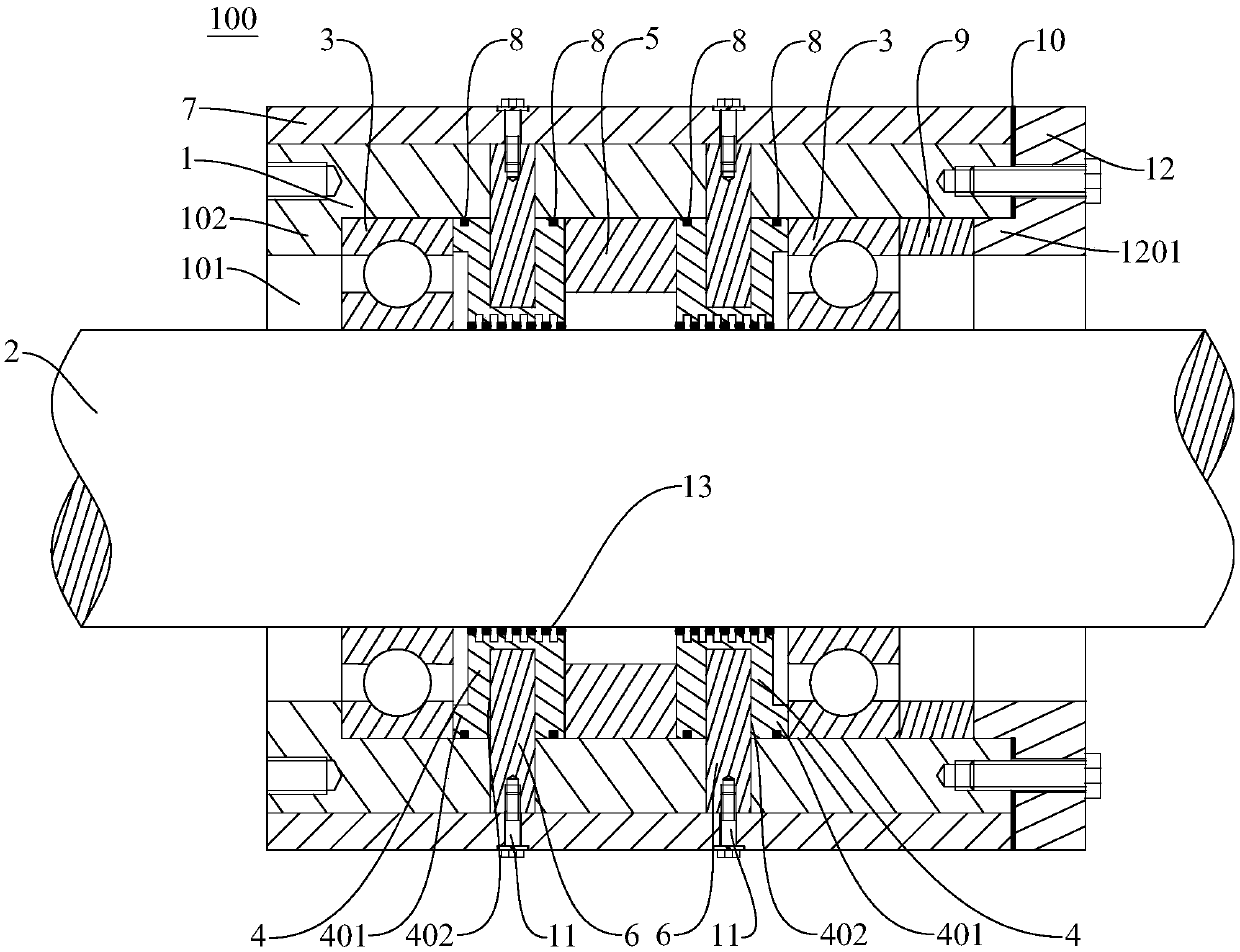

[0044] According to an embodiment of the present invention, a magnetic liquid sealing device 100 with a heat conduction rod and a heat dissipation sleeve includes a shaft housing 1, a rotating shaft 2, two bearings 3, two pole pieces 4, a permanent magnet 5, a heat conduction rod 6, a heat dissipation sleeve 7, a seal Ring 8, sleeve 9 and adjusting gasket 10.

[0045] The shaft housing 1 is provided with a shaft chamber 101, and the rotating shaft 2 is rotatably arranged in the shaft chamber 101. The rotating shaft 2 extends from one end of the shaft chamber 101 to the other end of the shaft chamber 101. Two bearings 3 are respectively sleeved on the rotating shaft 2. Above, two pole shoes 4 are sleeved on the rotating shaft 2 respectively, and are located between the two bearings 3, and a magnetic liquid 13 is adsorbed between the inner peripheral surface of each pole shoe 4 and the outer peripheral surface of the rotating shaft 2, and each pole There is a matching blind hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com