Booster-type drifter provided with replaceable drift diameter gauge device

A technology of calibrating machines and calibrating gauges, which is applied in the directions of measurement, wellbore/well parts, earthwork drilling, etc., can solve the problems of increasing the workload of on-site operators, reducing work efficiency, jamming of calibrating gauges, etc., and achieves Small footprint, improved production efficiency, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is further described:

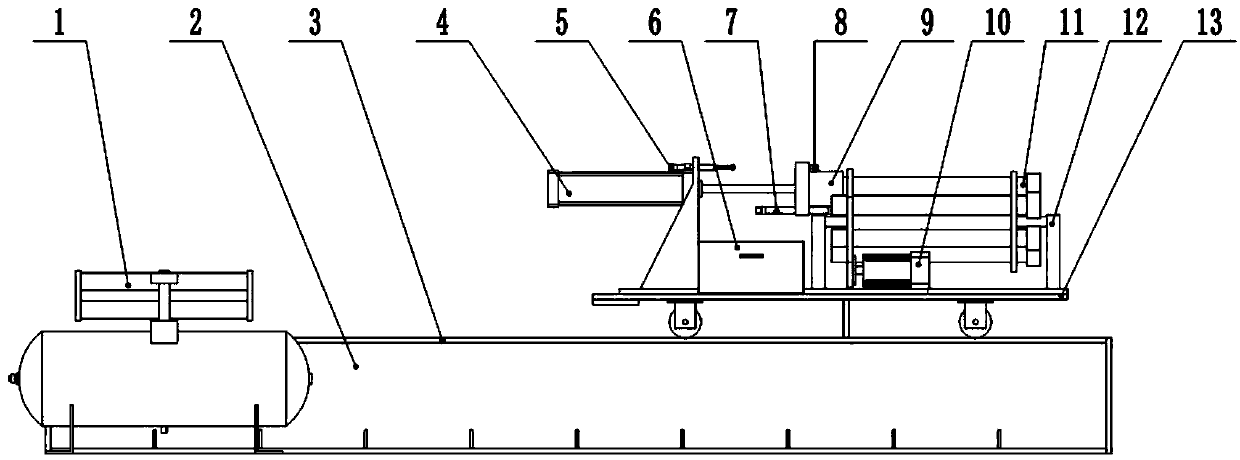

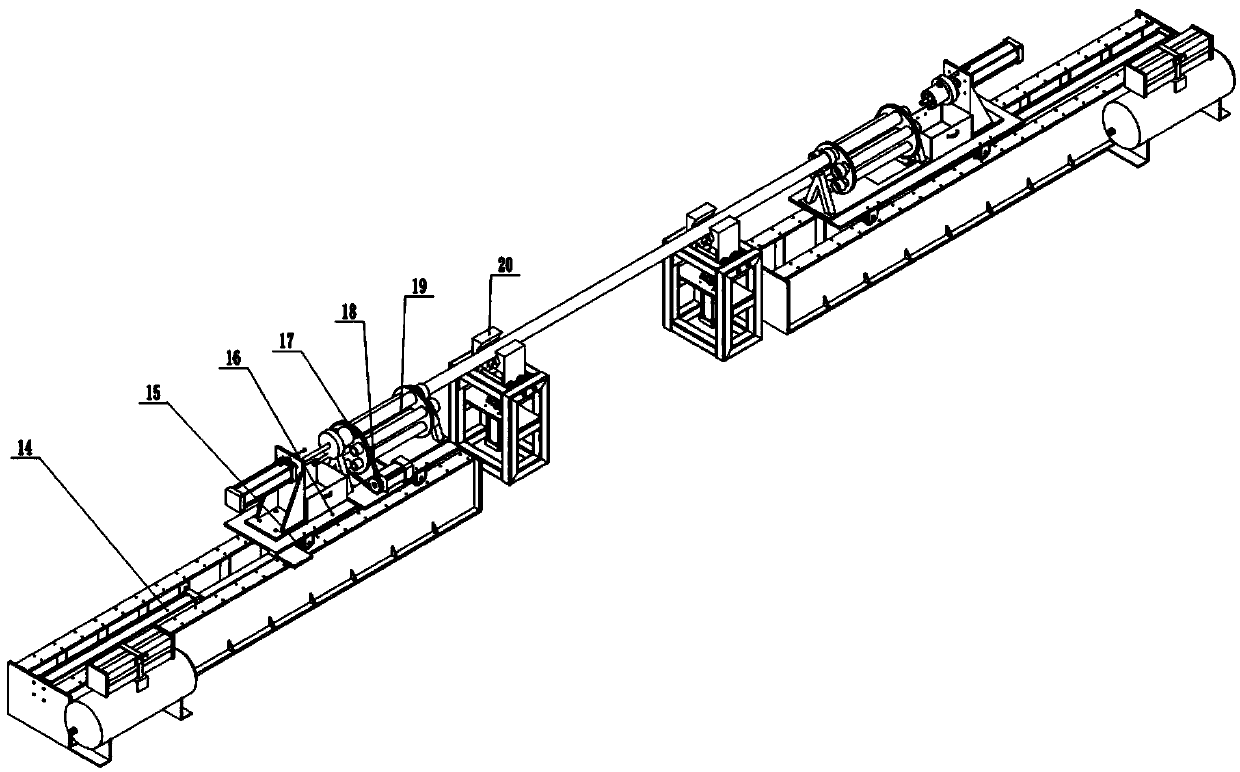

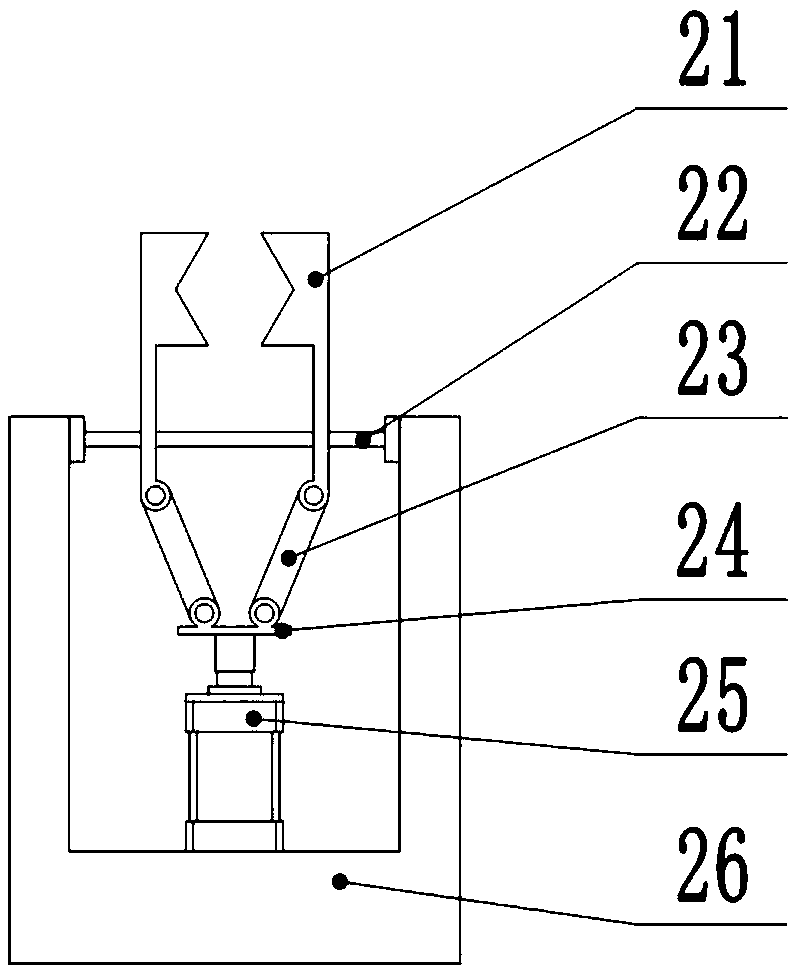

[0017] refer to Figure 1-4 , a pressurized bore machine with a replaceable bore gauge device, including a booster pump 1, a bore machine base 2, a guide rail 3, a base cylinder 14, a bore trolley 16 and a tubing clamping device 20. The inside of the diameter machine base 2 is fixed with the base cylinder 14, the top of the base cylinder 14 is connected to the bottom of the diameter trolley 16, the guide rail 3 is installed on the surface of the diameter machine base 2, the diameter trolley 16 is installed on the guide rail 3, and the booster pump 1 Installed behind the 2 sides of the calibrator base. The path trolley 16 comprises buffer cylinder 4, buffer damper 5, recovery box 6, abdication cylinder 7, air inlet 8, firing gun 9, path trolley base 13, path trolley roller 15 and replacement path gauge device 19. The trolley roller 15 is installed under the base 13 of the trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com