Metal complexes, organic electroluminescent devices, organic electroluminescent materials

A technology for electroluminescent materials and metal complexes, which is applied in the fields of luminescent materials, electro-solid devices, organic chemistry, etc., can solve the problems of low maximum external quantum efficiency, difficult ligand design of heavy metal complexes, etc., and achieves easy sublimation purification, Effects of improved external quantum efficiency and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0177] [Preparation method of metal complex]

[0178] Although the metal complex of the present invention is a new type of metal complex, its preparation method can be prepared by those skilled in the art under suitable conditions according to the technical knowledge in this field.

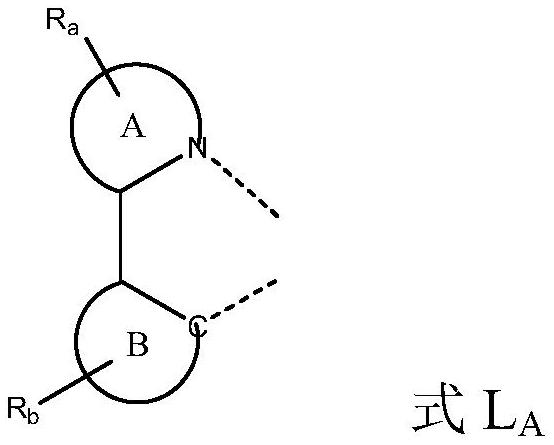

[0179] The aforementioned compounds LA1-LA1150 can be prepared by referring to the preparation methods of isoquinoline in patents CN104370968 and US20130146848. Specifically, the substituted o-cyanophenylethynyl trimethylsilane was prepared by reacting the substituted o-iodobenzonitrile as the starting material with trimethylsilyne under palladium catalyzed conditions, and the alkyne-containing intermediate was prepared under the alkaline condition of sodium ethoxide Substituted o-cyano-styryl ethyl ether is prepared by the following addition reaction, and the acetal product is easily ring-closed with the ortho-position imino group to prepare substituted isoquinoline ligands LA1-LA1150.

[0180] ...

Embodiment 1

[0204] Preparation of LA816:

[0205] The preparation method of LA816 comprises the steps:

[0206] The first step: preparation of intermediate L1

[0207]

[0208] 27.1 g (0.1 mol) of raw material L0 (4-isopropyl-2-iodobenzonitrile, CAS: 1369880-78-3), 0.11 mol of trimethylsilyne and 5 mmol of palladium acetate, 10 mmol of phosphide Copper, 10 mmol of triphenylphosphine, 50 mL of triethylamine and 200 mL of acetonitrile were stirred and reacted at room temperature for 4 hours under nitrogen protection. Concentrate to dryness under reduced pressure, decolorize the residue with a short silica gel column, and rinse with petroleum ether to obtain 23.0 g of product formula L1, yellow oil, yield: 96%.

[0209] The second step: the preparation of intermediate L2

[0210]

[0211] Put 200mL of ethanol into a 500mL reaction bottle, under the protection of nitrogen, add 11.0g of broken sodium blocks, stir and dissolve until the sodium blocks disappear, after 1 hour, add 23.0g ...

Embodiment 2

[0216] Preparation of LA2057:

[0217]

[0218] 18.0g (0.1mol) of raw material L3 (1-(o-aminophenyl)-3-methyl-1-butanol, CAS: 1341805-79-5), 83.3mmol of 3,5-dimethylphenethyl Ketone and 2 mmol of nickel catalyst (CAS: 757176-61-7), 0.1 mol of sodium tert-butoxide and 150 mL of toluene, under nitrogen protection, stirred and heated to reflux for 24 hours. Concentrated to dryness under reduced pressure, the residue was separated and purified by silica gel column to obtain 14.9g product formula LA2057, yellow oil, yield: 62%, 1 H-NMR: (δ, CDCl 3 ),8.20-8.18(d,1H),8.17-8.15(dd,2H),8.06-8.04(d,1H),7.74-7.68(m,2H),7.47-7.44(dd,1H),7.13(s ,1H), 3.17-3.10(m,2H), 2.43(s,6H), 1.53-1.50(m,1H), 1.01(s,6H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com