Hanging structure for preventing fracture of 3D high-aluminium glass runner cover board brick

A high-alumina glass and cover brick technology, which is applied in the direction of the feeding trough, etc., can solve the problems of cover brick breakage, increase in temperature difference between cover bricks and hanging parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

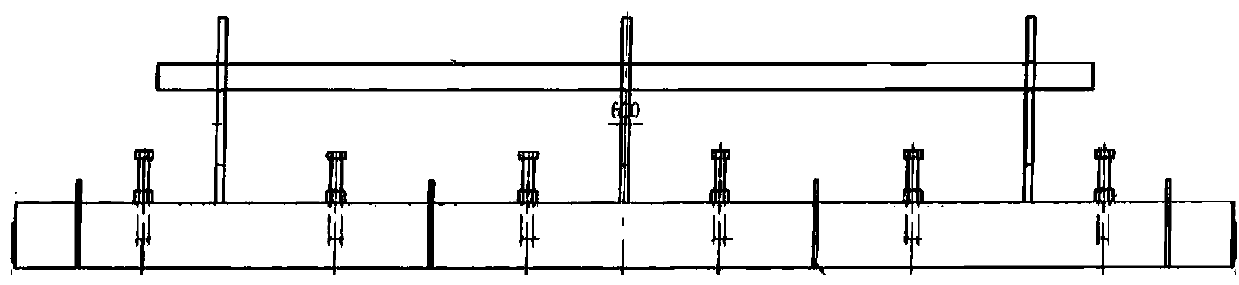

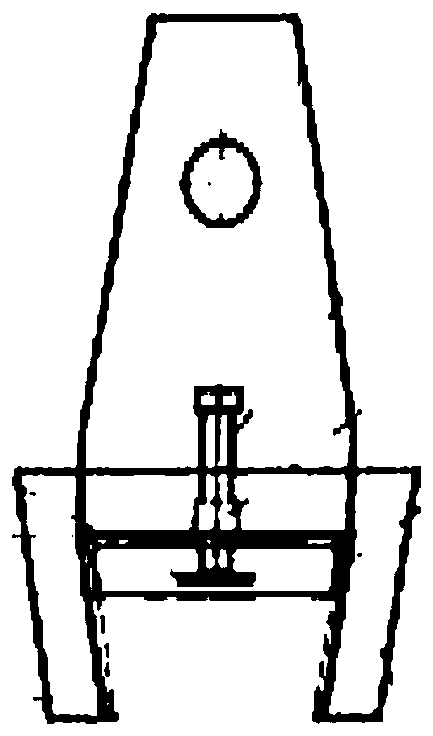

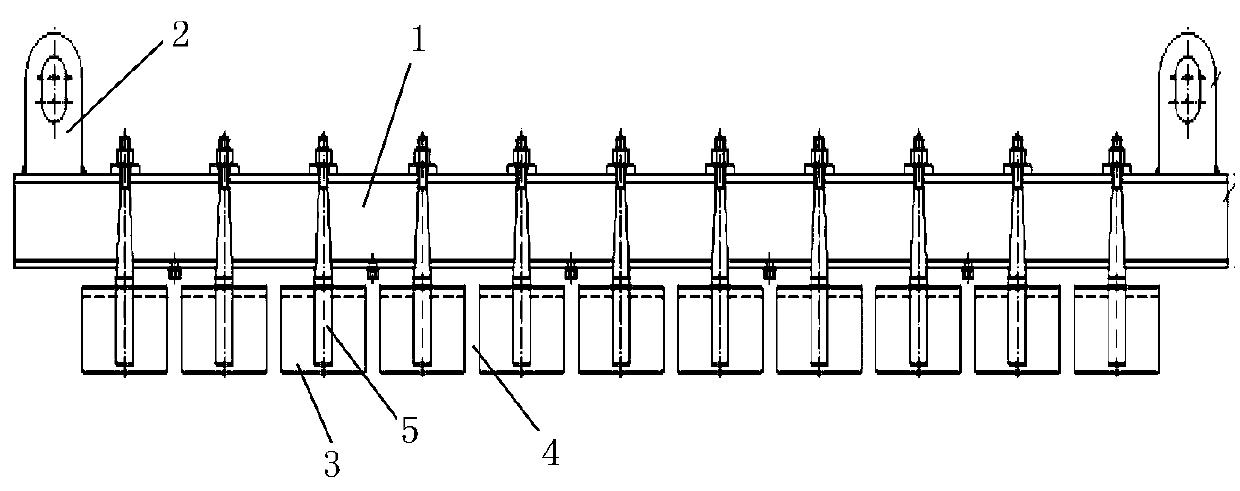

[0030] A hanging structure for preventing 3D high-alumina glass runner cover bricks from breaking, including a main beam 1 with lifting lugs 2 at both ends of the main beam, and the structure also includes a plurality of clamping plates for connecting cover bricks 3. The clamping plates are sequentially arranged under the main beam, and there is a gap 4 between two adjacent clamping plates, and both sides of the clamping plate are connected to the main beam through connecting pieces 5 .

[0031] Further, the main beam is an I-beam, one end of the connector is connected to the side of the clamping plate, and the other end is connected to the top of the I-beam. The main beam with I-beam structure has high strength and can adapt to high temperature working environment.

[0032] Further, the connecting piece is a flat steel, one end of which is fixedly connected to the outside of the side wall of the clamping plate, and the other end is welded with a bolt, and is fixedly connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com