Efficient cable winding drum with automatic cable arranging function

An automatic rowing and functional technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of low winding efficiency of cable reels and uneven distribution of cables, and achieve reasonable utilization of reels Tube space, improve the distribution range of cables, and facilitate transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

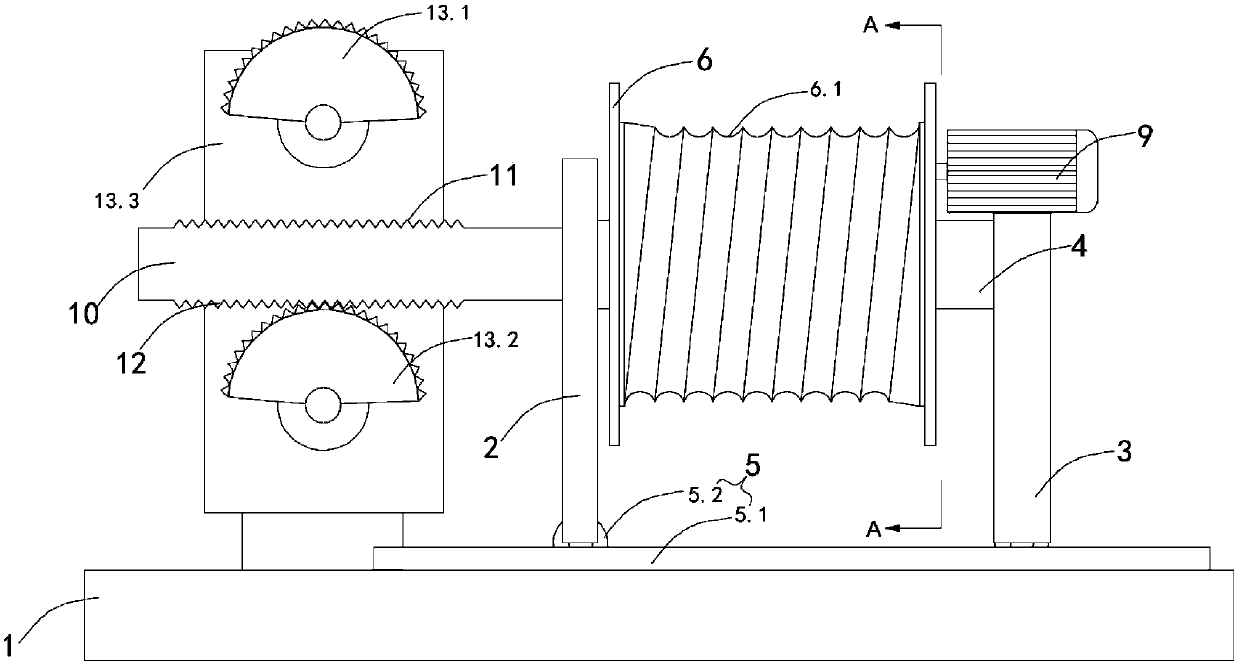

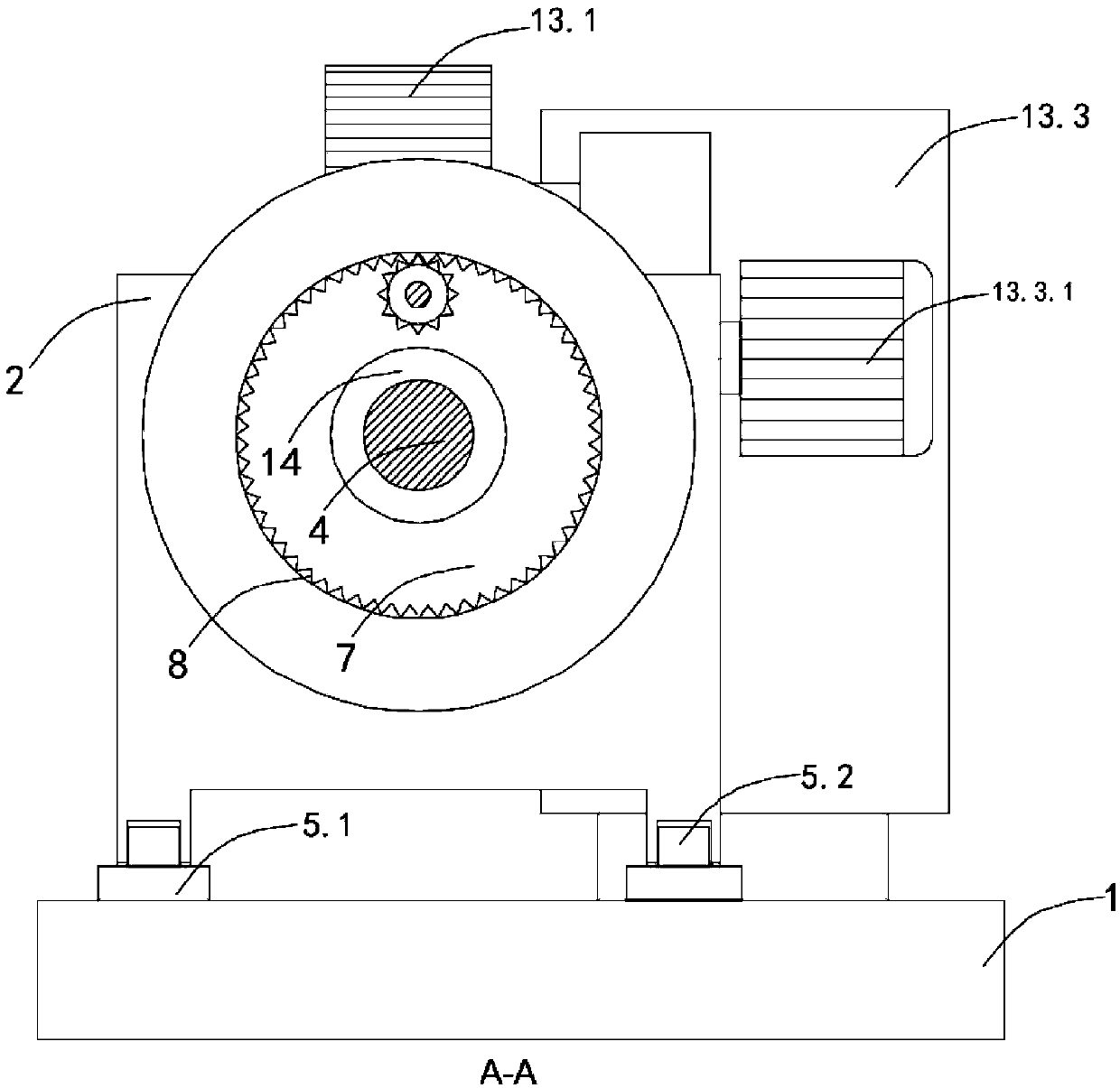

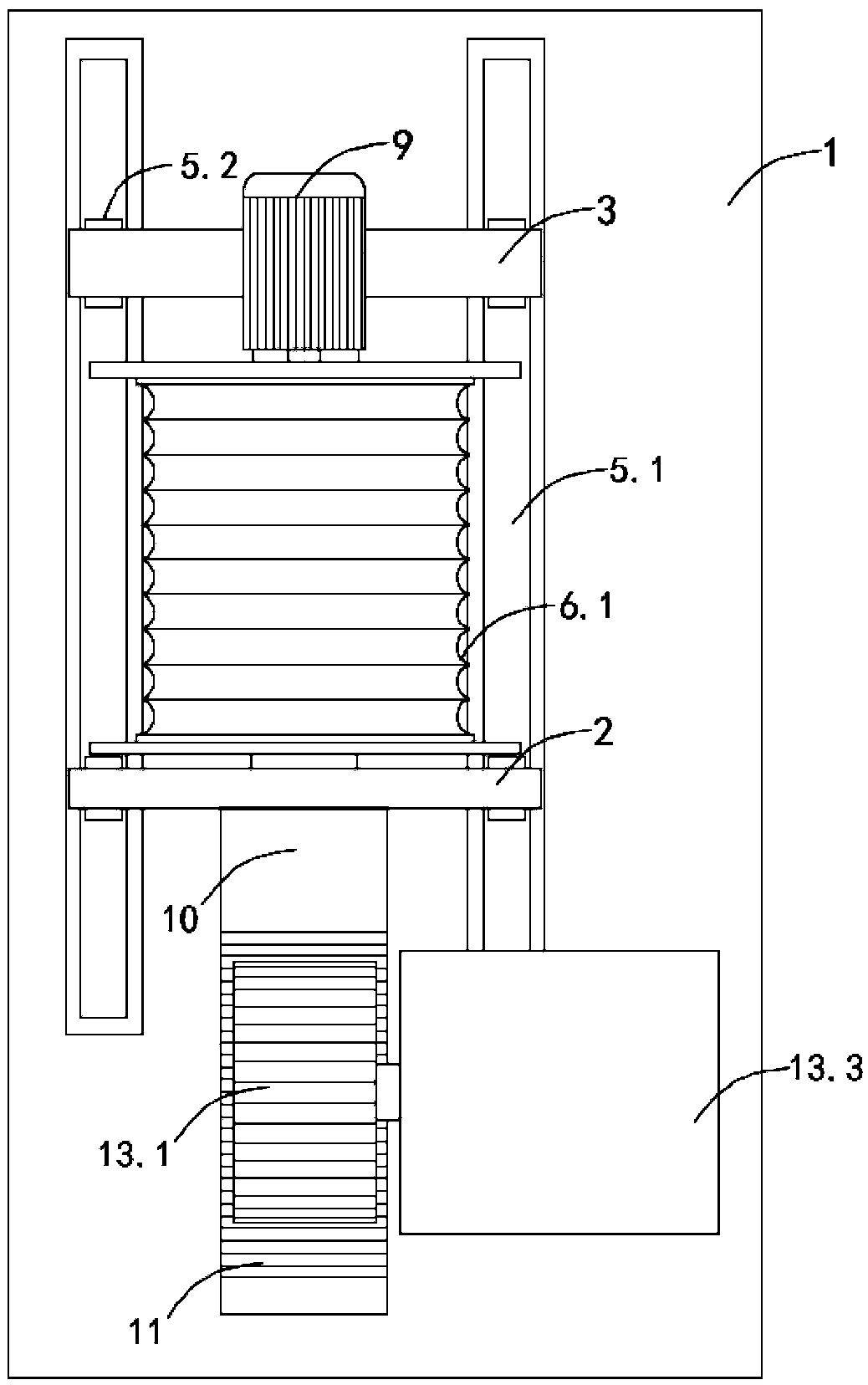

[0028] like Figure 1 to Figure 4 As shown, this embodiment provides a high-efficiency cable reel 6 with automatic cable removal function, including a base 1, a roller mechanism is provided on the right side of the top surface of the base 1, and the roller mechanism includes a left fixing plate 2 and a right fixing plate 3 and the connecting shaft 4 fixed between the left fixed plate 2 and the right fixed plate 3, the bottom of the left fixed plate 2 and the right fixed plate 3 are provided with a sliding mechanism 5 fixed on the top surface of the base 1, and the connecting shaft 4 passes through multiple The first bearing is provided with a reel 6, and the right wall of the reel 6 is provided with a ring groove 7 around the axis of the reel 6, and the inner wall of the ring groove 7 is provided with a first tooth groove 8, and the first tooth groove 8 is connected with the gear arranged inside the ring groove 7. Cooperate, the gear is connected with the rotating motor 9 fixe...

Embodiment 2

[0031] like Figure 1 to Figure 3 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0032]The sliding mechanism 5 includes two slide rails 5.1 fixed on the top surface of the base 1 and parallel to each other. The direction of the slide rails 5.1 is the same as that of the connecting shaft 4 axis. The roller 5.2 of right fixed plate 3.

[0033] In this embodiment, there is rolling friction between the slide rail 5.1 and the roller 5.2, so that the resistance of the left and right reciprocating motion of the entire cable reel 6 is minimized, and the purpose of reducing energy consumption and cost is achieved.

Embodiment 3

[0035] like Figure 1 to Figure 3 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0036] The transmission device 13 includes a first incomplete gear 13.1 that can mesh with the second tooth groove 11, a second incomplete gear 13.2 that can mesh with the third tooth groove 12 and has the same structure as the first incomplete gear 13.1, and is fixed on the base In the power case 13.3 on 1, the range of tooth groove angles of the first incomplete gear 13.1 and the second incomplete gear 13.2 is between 170° and 180°, and the number of tooth grooves of the first incomplete gear 13.1 is the same as that of the second tooth The number of tooth grooves of the groove 11 is equal, and the second incomplete gear 13.2 is not meshed with the third tooth groove 12 when the first incomplete gear 13.1 meshes with the second tooth groove 11, and the turning direction of the first incomplete gear 13.1 is the same as that of the second incomplete ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com