A five-axis EDM closed impeller trajectory planning method

A closed impeller and trajectory planning technology, which is applied to instruments, image data processing, etc., can solve the problems of difficulty in inter-electrode gap control and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

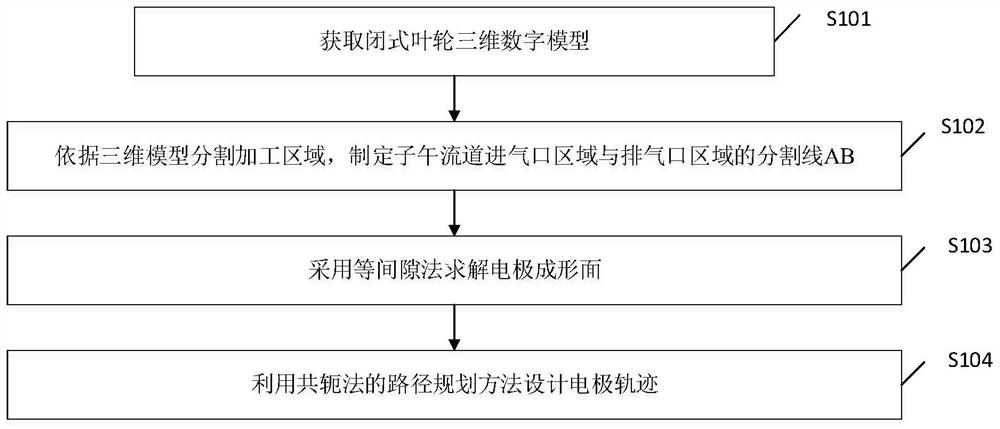

[0030] The present invention provides an embodiment of a five-axis electric discharge machining closed impeller track planning method, in order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purpose and characteristics of the present invention And advantage can be more obvious and easy to understand, below in conjunction with accompanying drawing, technical solution in the present invention is described in further detail:

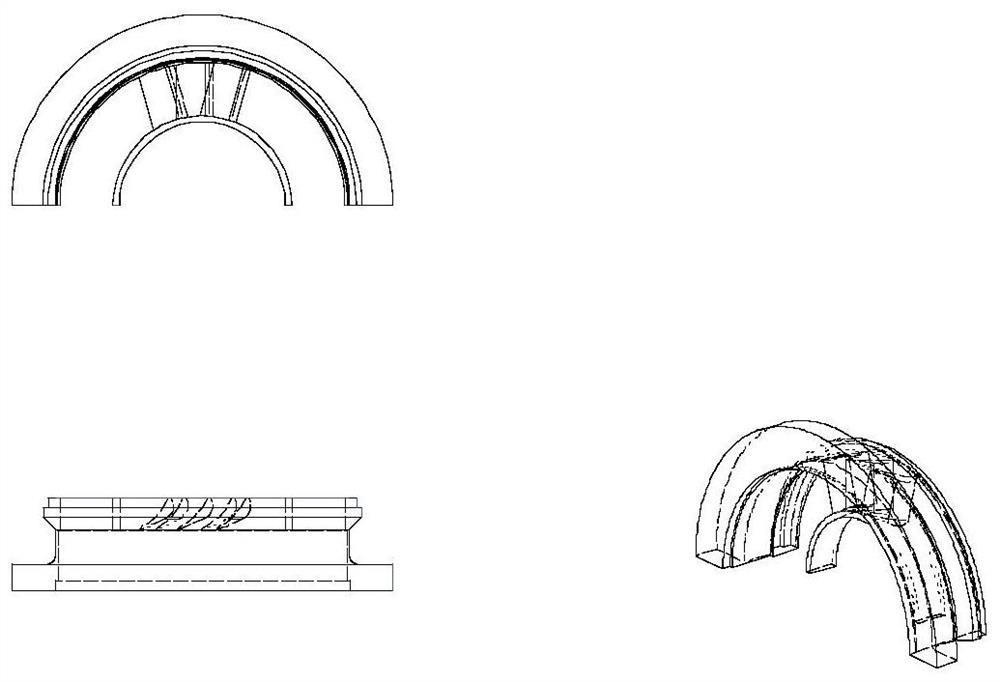

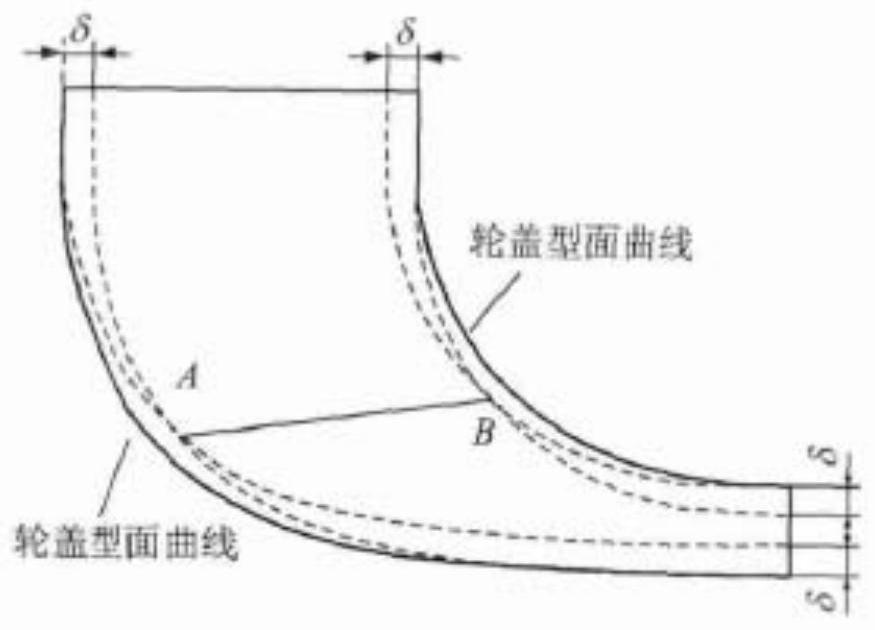

[0031] The present invention is realized by the following method: a five-axis electric discharge machining closed impeller track planning method such as figure 1 As shown, step 1 S101, obtain the three-dimensional digital model of the closed impeller, define the surface of the blade pot as A, the curved surface of the blade back as B, the surface of the inner hub as H, and the surface of the outer hub as S, the curved surface of the leading edge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com