A new type of bus duct with high efficiency and anti-leakage

A busway and anti-leakage technology, applied in the field of busbars, can solve the problems of inability to repair and replace, low use efficiency, complicated connection between the shell and the side plate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

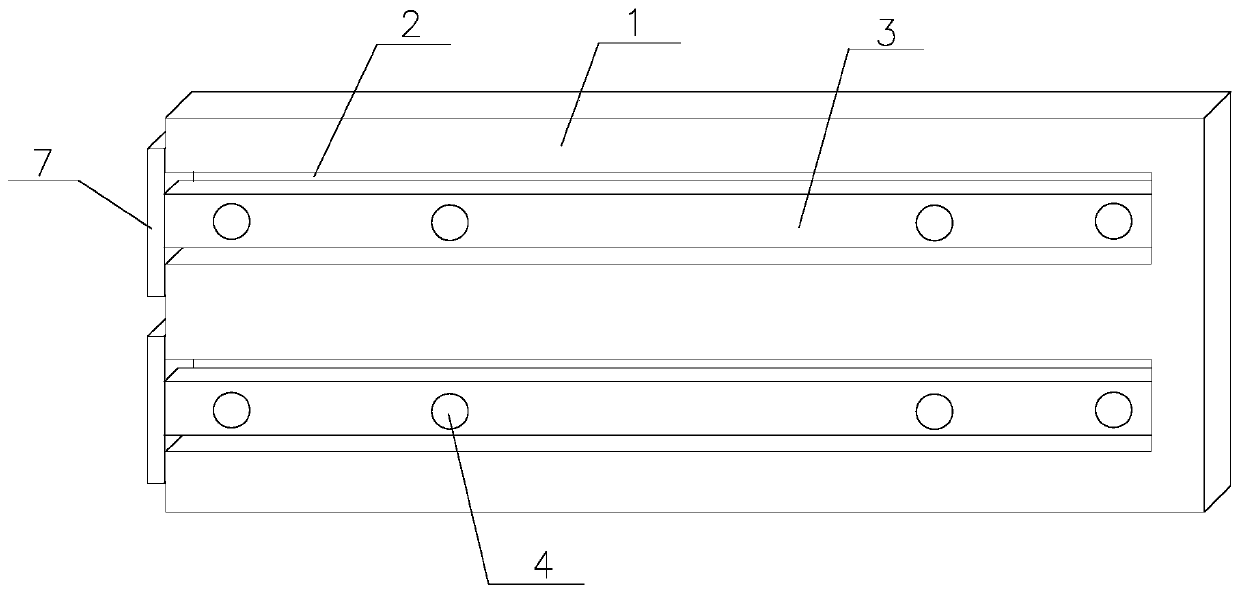

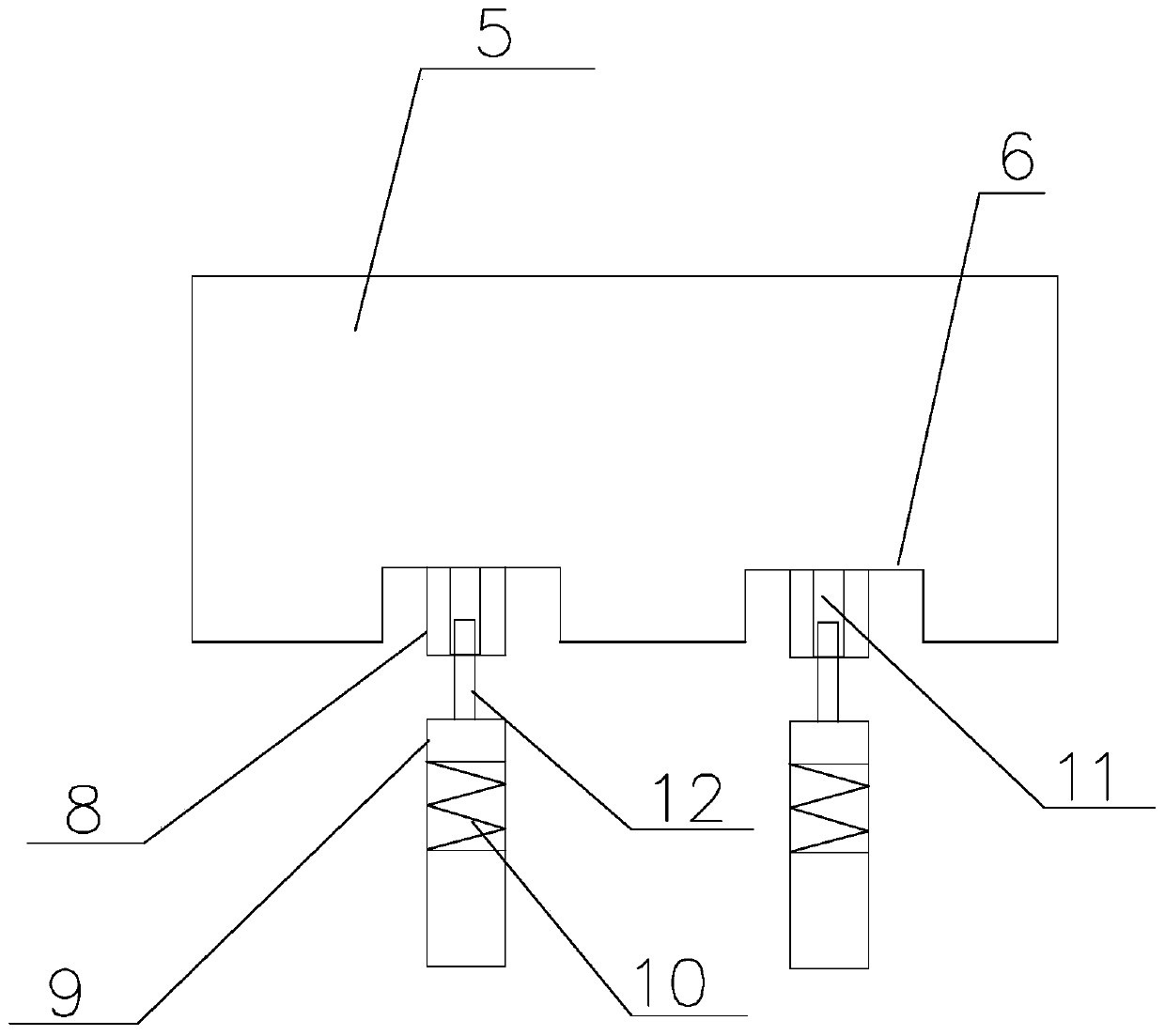

[0028] Such as Figure 1~2 As shown, the new type bus duct with high efficiency and leakage prevention of the present invention includes a bus duct side plate 1, a flame-retardant partition 5, and two parallel first grooves 2 and first grooves 2 are provided on the bus duct side plate 1 One end is in the busway side plate 1, and the other end penetrates through one end of the busway side plate 1. The first groove 2 is provided with a connecting plate 3, one end of the connecting plate 3 is connected to the spring, and the other end of the spring is connected to the first concave The groove 2 is connected at one end in the side plate 1 of the busbar, and the other end of the connecting plate 3 is outside the first groove 2. Under the action of the spring, the connecting plate 3 moves along the line where the first groove 2 is located;

[0029] The connecting plate 3 is provided with a through hole 4 for connecting the flame-retardant partition plate 5, and the through hole 4 is pr...

Embodiment 2

[0032] On the basis of embodiment 1, the middle part of the connecting plate 9 is a spring 10 that can expand and contract along the line where the connecting plate 9 is located. A through groove 11 is provided in the rotating plate 8. The through groove 11 and the connecting plate 9 are on the same vertical straight line. An adjusting rod 12 is connected between the connecting plate 9 and the rotating plate 8. The adjusting rod 12 passes through the thread and the through groove. 11 is connected, and by rotating the adjusting rod 12, the distance between the upper end of the connecting plate 9 and the rotating plate 8 is adjusted.

Embodiment 3

[0034] A new type of bus duct with high efficiency and anti-leakage. The connecting plate 3 is vertically connected with a positioning plate 7 on one end outside the bus duct side plate 1. The positioning plate 7 is outside the bus duct side plate 1, and the positioning plate 7 is in contact with the bus duct side plate 1. An iron absorption layer is arranged on the surface of the, and the positioning plate 7 is fixedly connected with the side plate 1 of the busbar through the iron absorption layer. The width of the second groove 6 is the same as the width of the first groove 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com