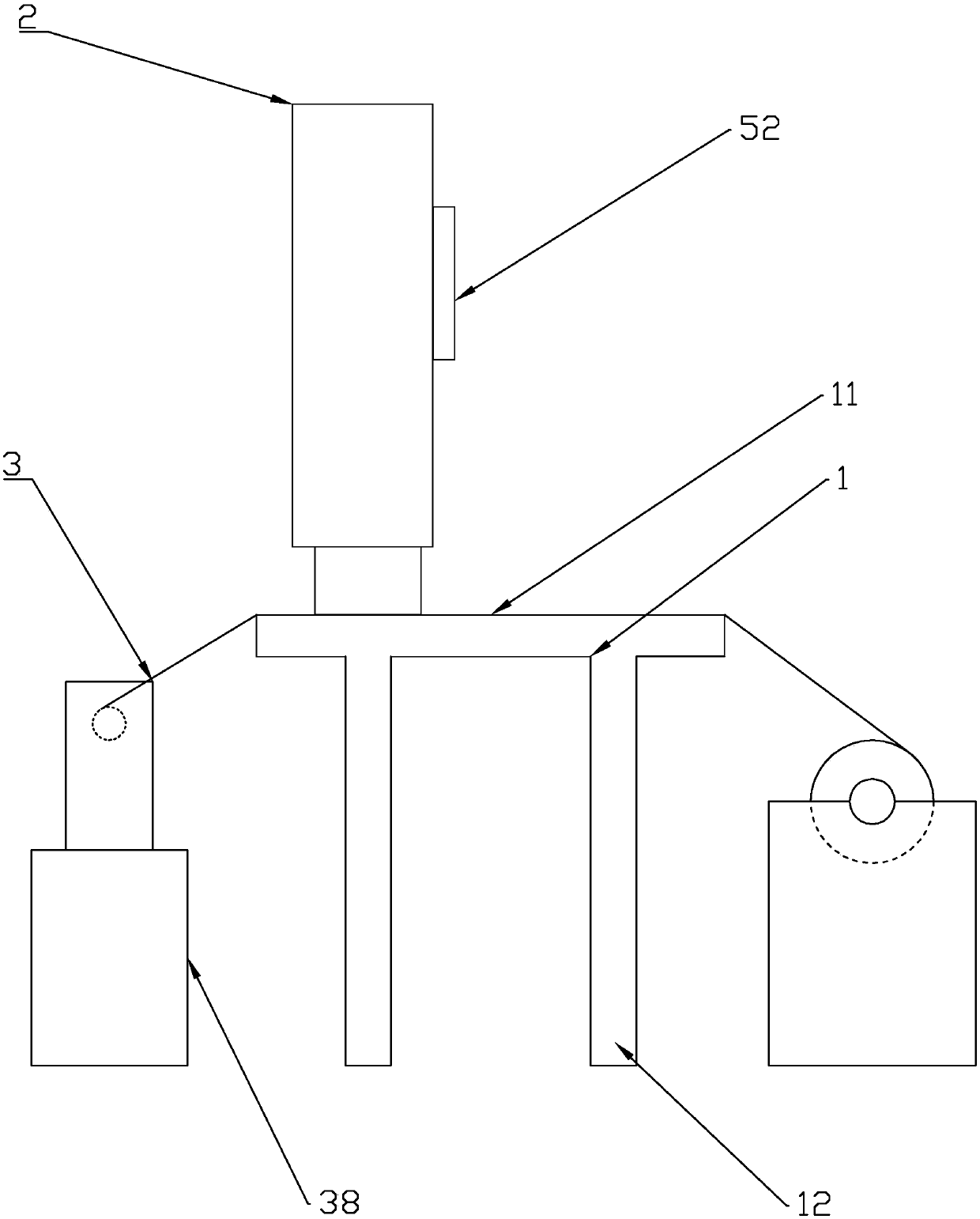

Dust removal device for spinning equipment

A technology of dust removal device and textile equipment, which is applied in textiles and papermaking, transportation and packaging, winding strips, etc., and can solve problems such as high labor costs and poor dust collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

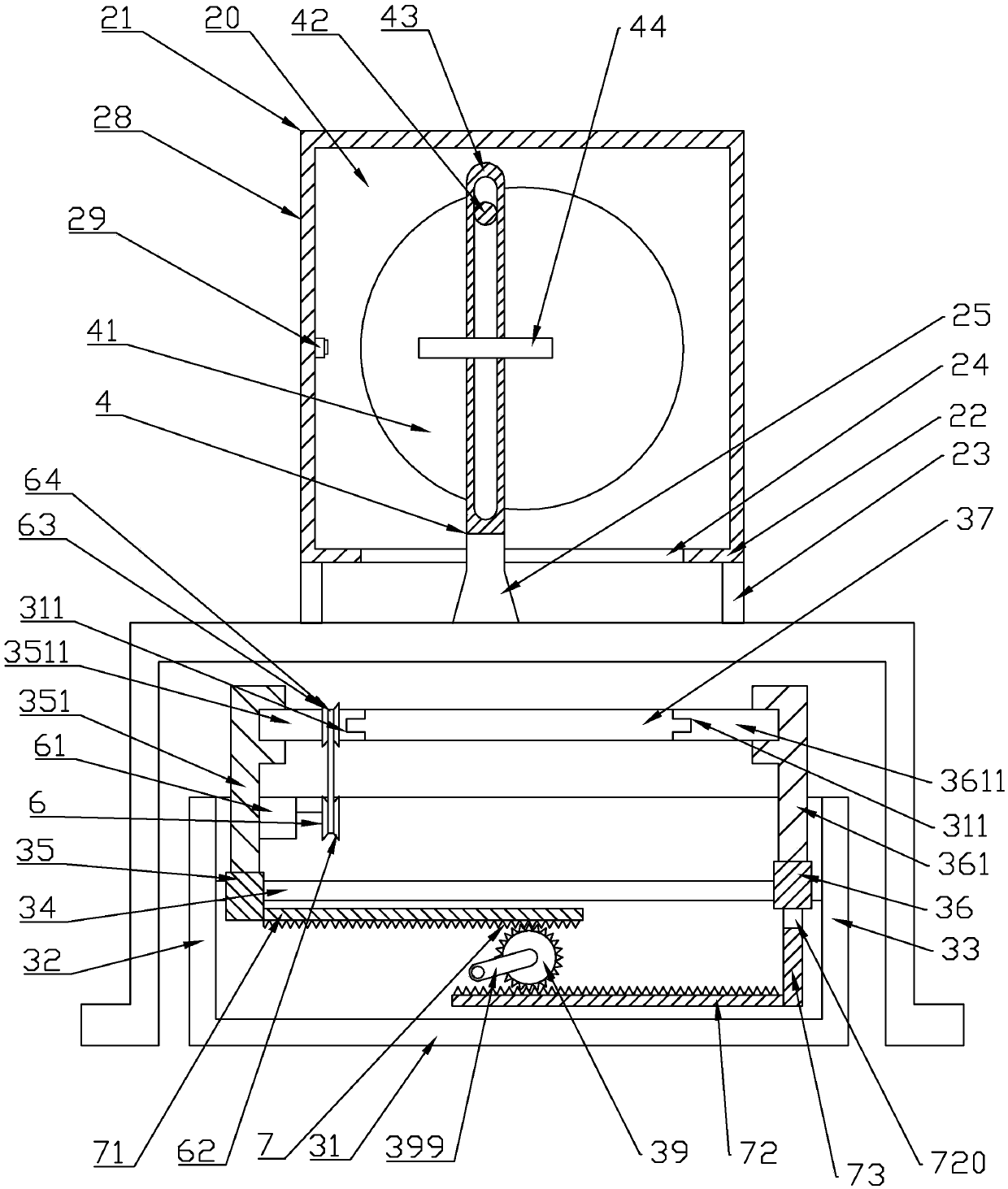

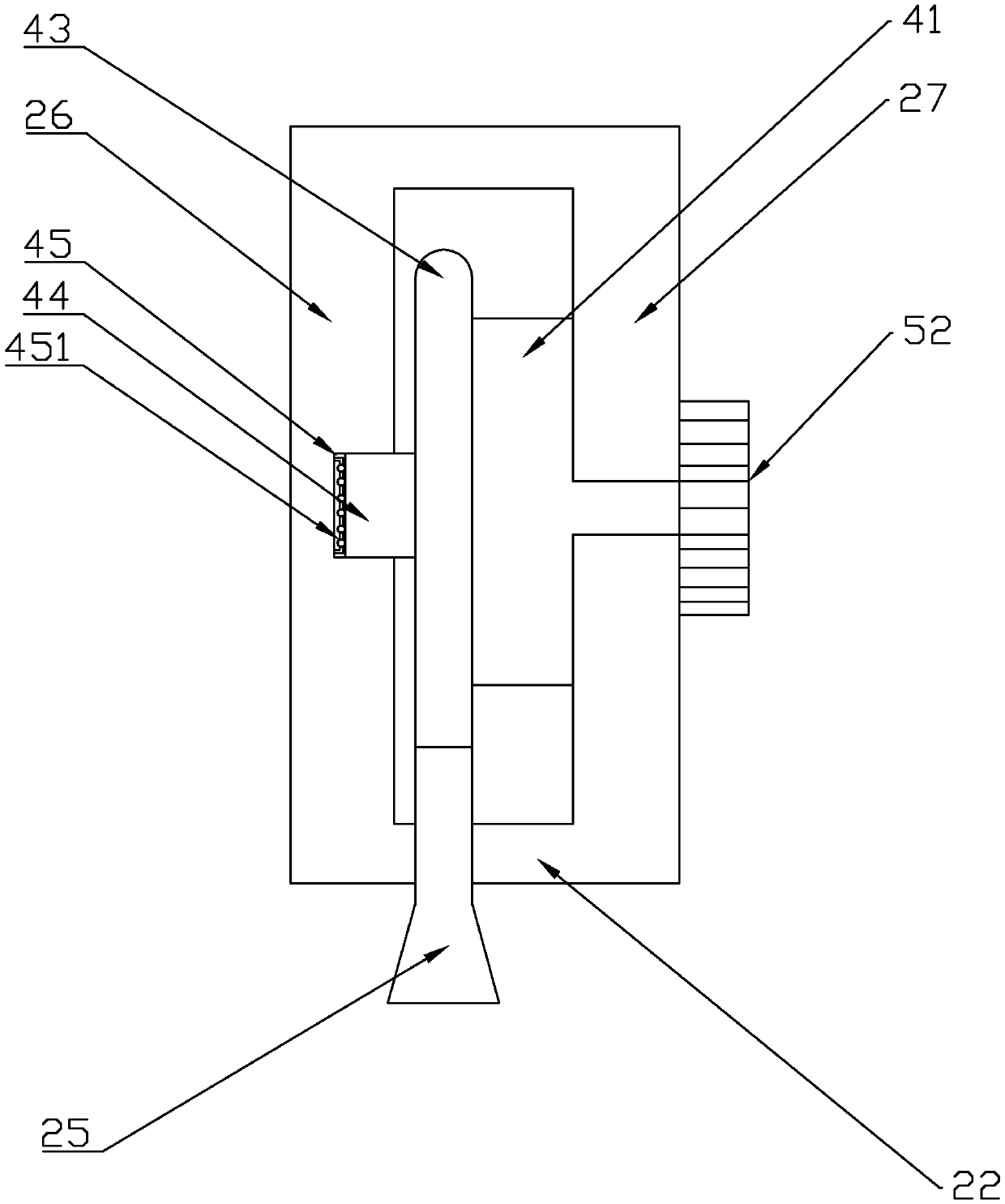

[0026] As an improved specific embodiment, the housing 21 includes a third side plate 28, the third side plate 28 is located between the first side plate 26 and the second side plate 27, the third side plate 28 A button switch 29 is arranged on the side facing the cavity 20, and the button switch 29 is used for starting the winding mechanism 3 when the slide plate 44 is pressed.

[0027] Through the above technical scheme: when the bump 42 rotates close to the button switch 29, it drives the slide plate 44 to move toward the button switch 29 along the chute 45, and when the slide plate 44 presses the button switch 29, the winding mechanism 3 is started, and the textile cloth is Winding, at the same time, through the intermittent mechanism 5, the passive wheel 51 stops rotating, so that the turntable 41 stops rotating, and the vacuum cleaner is stationary. The wheel 51 continues to rotate, the turntable 41 rotates, the vacuum cleaner moves on the next piece of textile cloth and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com