Split-type modular flat membrane combiner

A flat membrane module, modular technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as inconvenient rapid deployment, save self-priming pumps, improve The effect of the sinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

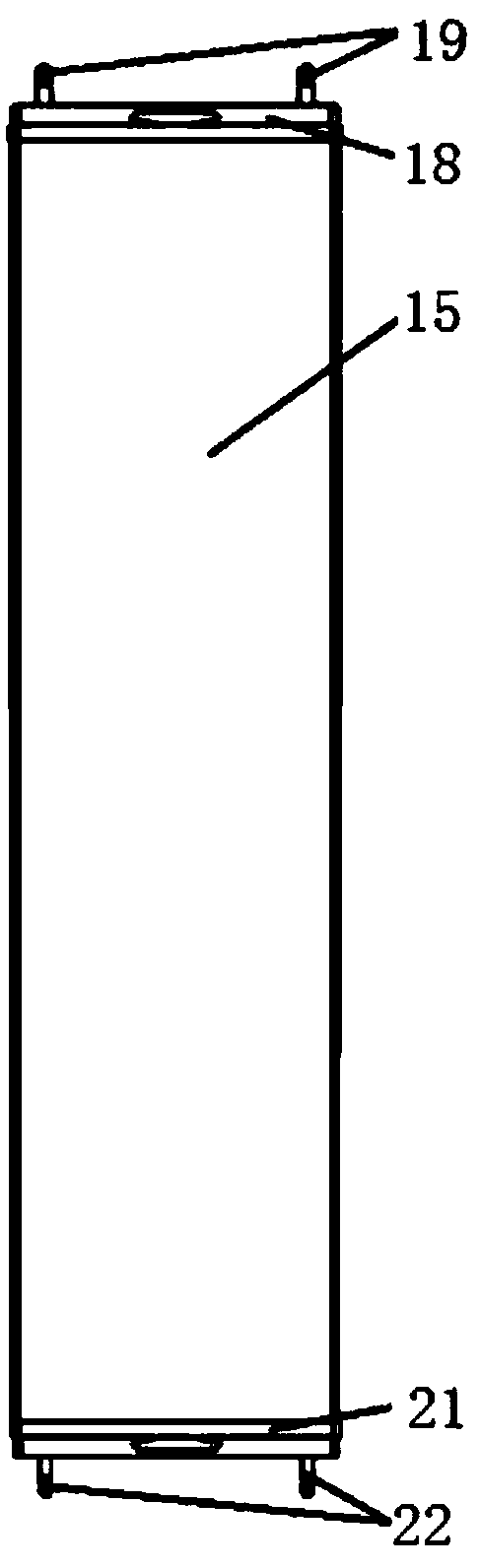

[0034] A split-type modular flat-panel membrane unit, which includes a flat-panel membrane element 1, an upper header 2, a lower header 8, a casing 11 and an overflow plate 4, the overflow plate 4 is fixedly installed in the casing 11, and the overflow The flow plate 4 divides the shell 11 into two parts: the water inlet sedimentation chamber 5 and the membrane chamber 6. A set of flat membrane elements 1 are installed in the membrane chamber 6. The upper outlets of the flat membrane elements 1 are connected to the upper header 2. The collecting pipe 2 is connected with the upper production water port 10 on the casing, the upper production water port 10 is connected with the vacuum pipe, the cleaning pipeline and the exhaust port, and the vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com