Conveniently-adjusted type woven ribbon printing device

A printing device and an adjustable technology, which is applied in the field of ribbon printing, can solve the problems of unable to dry ink in time, reduce product quality, and smearing of ribbons, so as to improve printing effect, avoid smearing, and avoid excessive tension or the effect of excessive relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

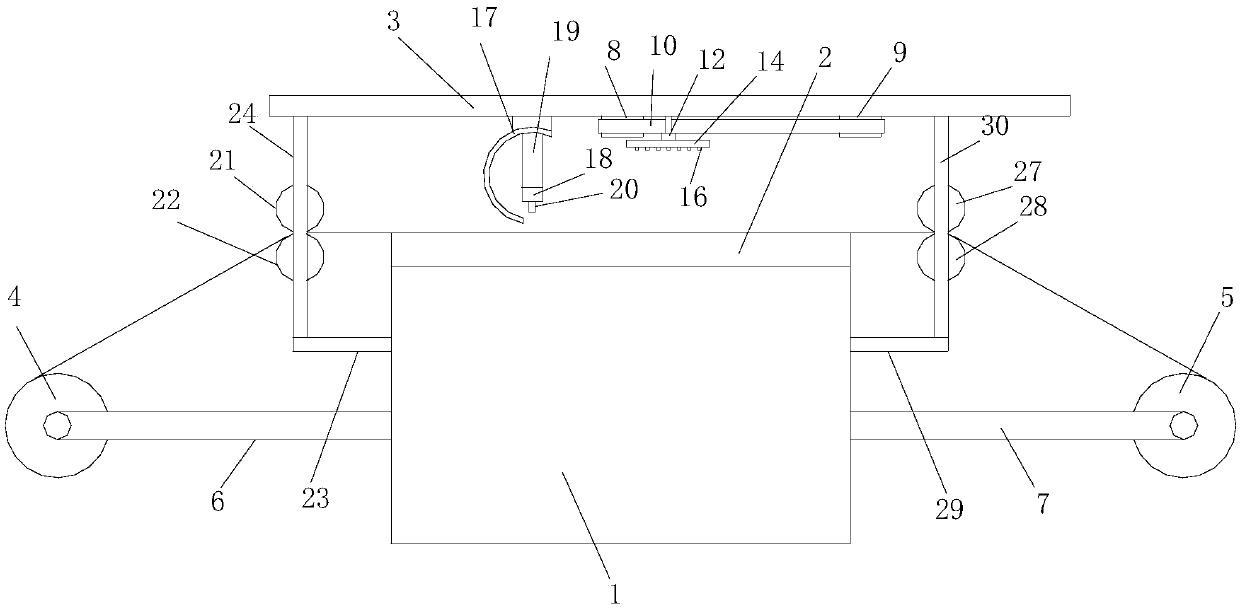

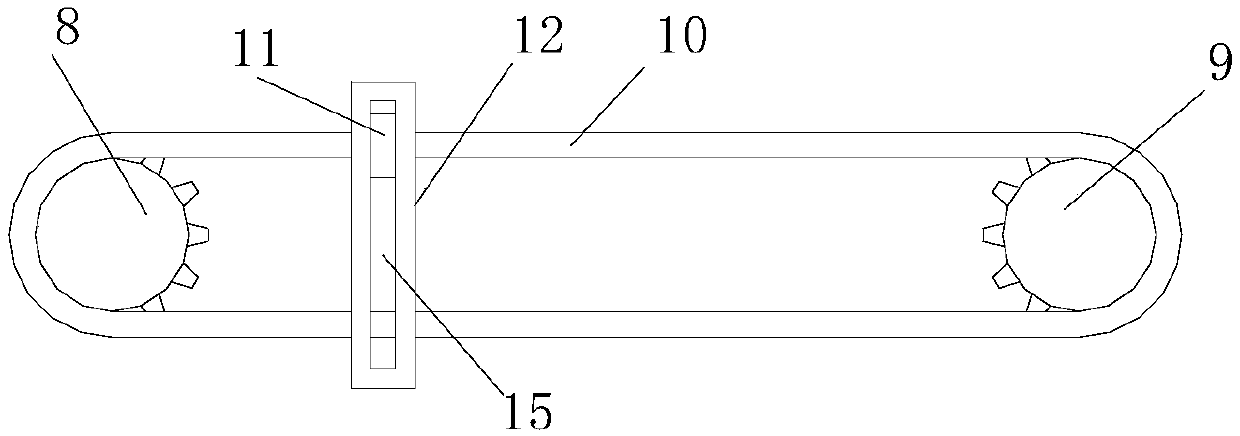

[0021] refer to Figure 1-Figure 5 , the present invention proposes an easy-to-adjust ribbon printing device, including a base 1, a printing plate 2, a mounting plate 3, a ribbon unwinding roller 4, a ribbon take-up roller 5, a printing mechanism and a drying mechanism, in:

[0022] The printing board 2 is arranged horizontally and the printing board 2 is installed on the top of the base 1 . The mounting board 3 is located above the printing board 2 and parallel to the printing board 2 .

[0023] Weaving satin ribbon unwinding roller 4 and weaving satin ribbon take-up roller 5 are arranged parallel to each other, and weaving satin ribbon unwinding roller 4 is arranged on printing plate 2 feeding end side and the height of weaving satin ribbon unwinding roll 4 is lower than printing plate The height of 2, weaving satin ribbon puts tape roller 4 and is installed on the base 1 by the first support 6. The satin ribbon take-up roller 5 is arranged on one side of the discharge en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com