A garment printing device

A printing device and printing technology, applied in printing devices, printing, typewriters, etc., can solve problems that affect the work efficiency of operators, cannot meet the use requirements, and clothes have a strong smell, so as to improve the wearing effect, avoid bacterial growth, pattern clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

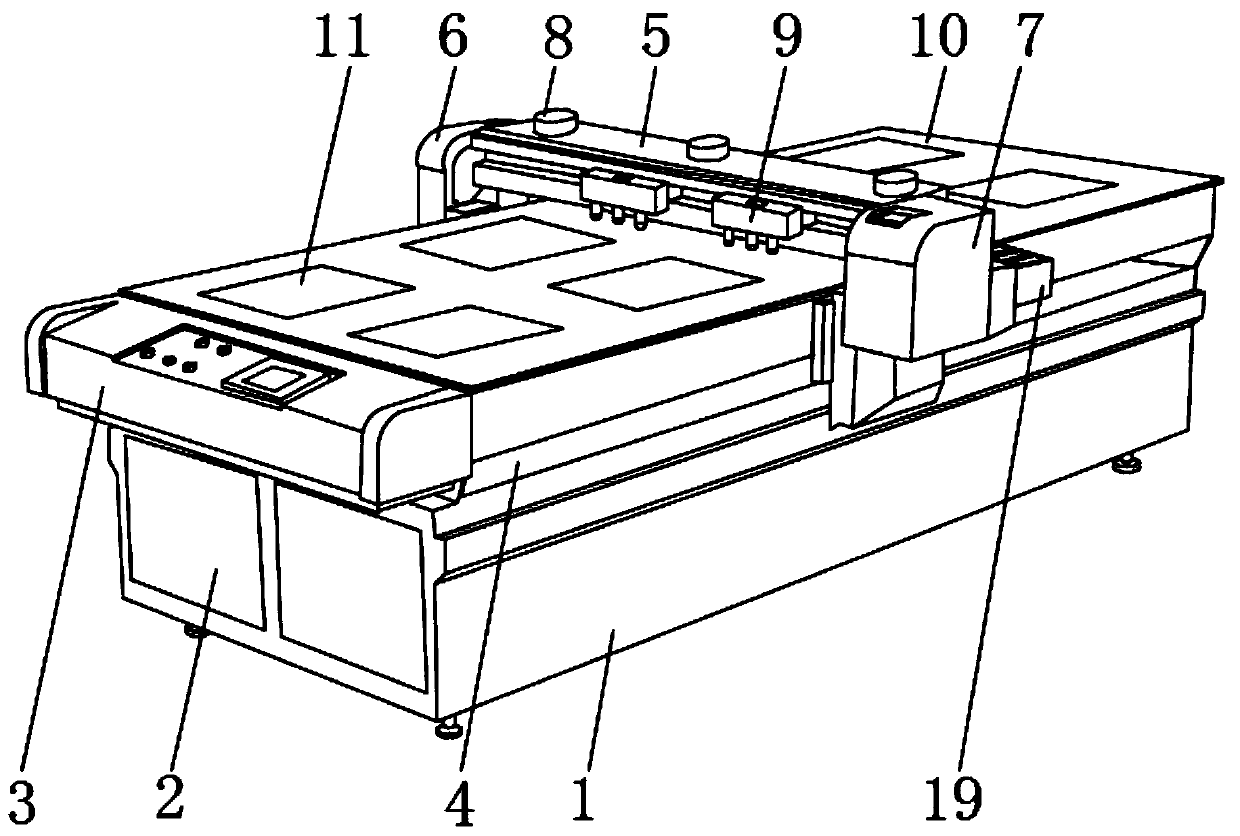

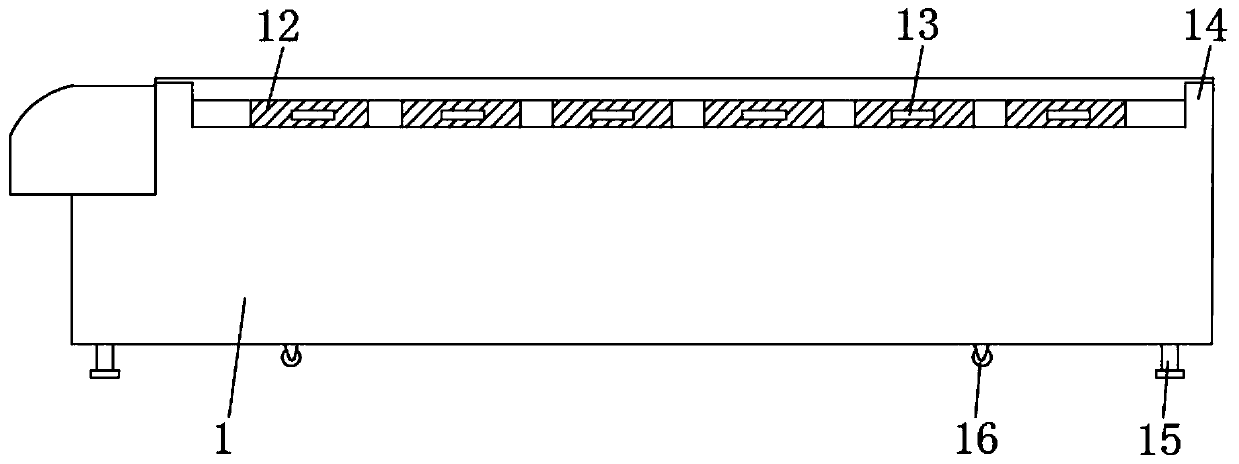

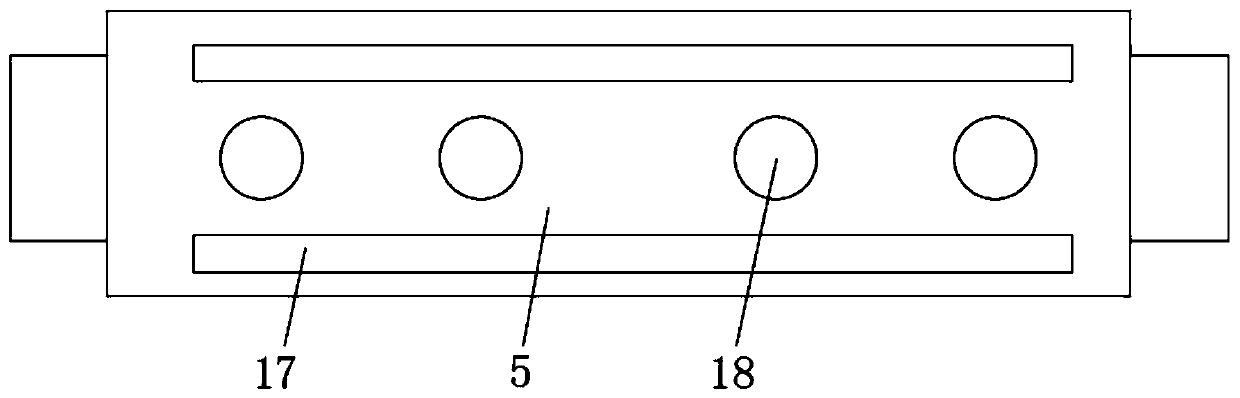

[0027] Such as Figure 1-4 As shown, a garment printing and printing device includes a device main body 1, the outer surface of the front end of the device main body 1 is fixed with a maintenance door 2 by bolts, the upper end outer surface of the device main body 1 is fixedly installed with a machine head 3 near the front end, and the main body of the device The outer surfaces of both sides of 1 are provided with chute 4 close to the upper end position, and the upper part of the device main body 1 is provided with a movable rod 5, and the two ends of the movable rod 5 are fixedly installed with a movable block 6, and the outer surface of the front end of the movable block 6 is fixedly installed. There is an operation box 7, and the outer surface of the upper end of the movable rod 5 is fixed with several groups of fans 8 by bolts. A metal plate 10 is fixedly installed on the outer surface, and several groups of clothes 11 are arranged on the outer surface of the upper end of ...

Embodiment 2

[0030] Such as Figure 1-4 As shown, a garment printing and printing device includes a device main body 1, the outer surface of the front end of the device main body 1 is fixed with a maintenance door 2 by bolts, the upper end outer surface of the device main body 1 is fixedly installed with a machine head 3 near the front end, and the main body of the device The outer surfaces of both sides of 1 are provided with chute 4 close to the upper end position, and the upper part of the device main body 1 is provided with a movable rod 5, and the two ends of the movable rod 5 are fixedly installed with a movable block 6, and the outer surface of the front end of the movable block 6 is fixedly installed. There is an operation box 7, and the outer surface of the upper end of the movable rod 5 is fixed with several groups of fans 8 by bolts. A metal plate 10 is fixedly installed on the outer surface, and several groups of clothes 11 are arranged on the outer surface of the upper end of ...

Embodiment 3

[0034] Such as Figure 1-4As shown, a garment printing and printing device includes a device main body 1, the outer surface of the front end of the device main body 1 is fixed with a maintenance door 2 by bolts, the upper end outer surface of the device main body 1 is fixedly installed with a machine head 3 near the front end, and the main body of the device The outer surfaces of both sides of 1 are provided with chute 4 close to the upper end position, and the upper part of the device main body 1 is provided with a movable rod 5, and the two ends of the movable rod 5 are fixedly installed with a movable block 6, and the outer surface of the front end of the movable block 6 is fixedly installed. There is an operation box 7, and the outer surface of the upper end of the movable rod 5 is fixed with several groups of fans 8 by bolts. A metal plate 10 is fixedly installed on the outer surface, and several groups of clothes 11 are arranged on the outer surface of the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com