Asynchronous die-cutting method with small holes in place and asynchronous die-cut products with small holes in place

A die-cutting and asynchronous technology, applied in chemical instruments and methods, layered products, lamination, etc., can solve the problems of large typesetting gap and low utilization rate of main materials for die-cutting products, so as to improve the utilization rate of main materials and save energy. The effect of material cost and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

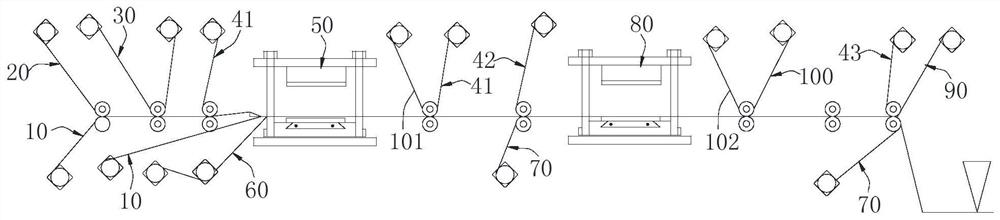

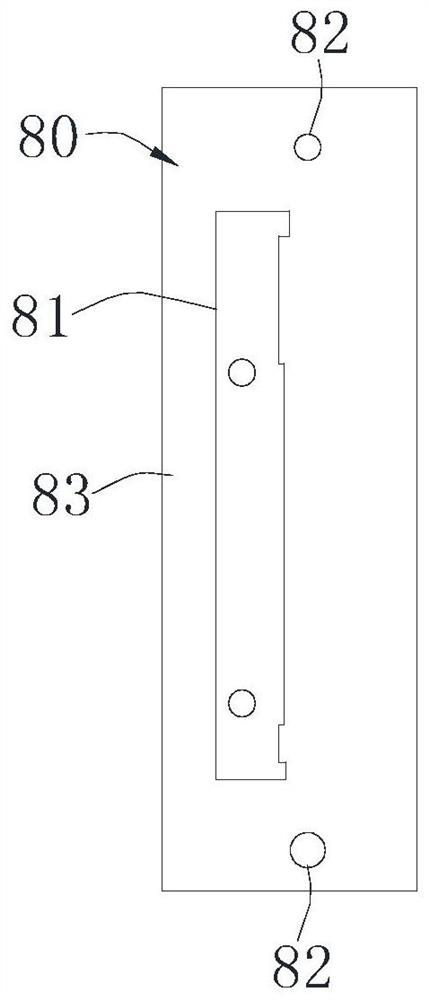

[0035] refer to Figure 1-3 , an asynchronous die-cutting method with small holes in one embodiment of the present invention is used to prepare die-cut products. The method may include the following steps:

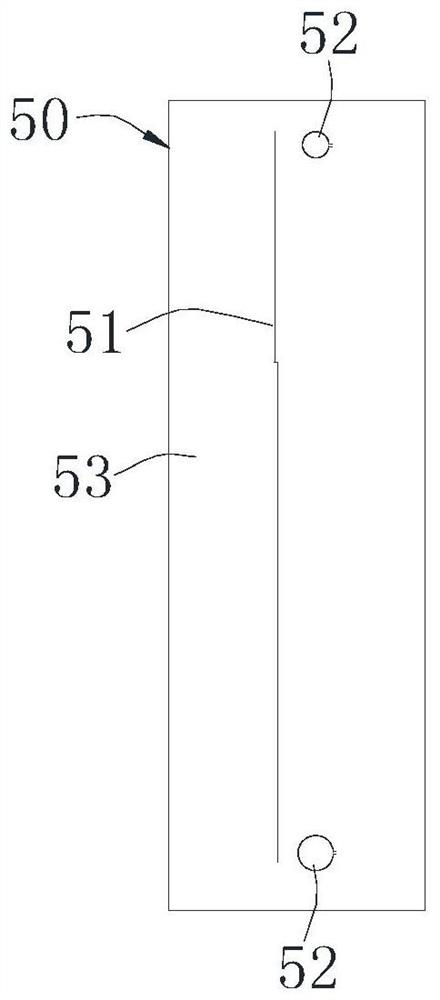

[0036] S1. Lay the main material and the first release film 41 sequentially on the first base film 10 , and transfer to the first die 50 with a first jump distance.

[0037] In this embodiment, the main material includes foam 20 and double-sided adhesive 30 , and the foam 20 and double-sided adhesive 30 are sequentially laminated on the first bottom film 10 . Understandably, depending on the die-cut product, the main material can be one or more of foam, double-sided tape, Mylar and conductive cloth.

[0038] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com