Roast drawstring production equipment and production process

A production process and technology of plastic ropes, which can be used in rope-making auxiliary devices, textiles and papermaking, textile cables, etc., and can solve problems such as easy detachment of silk from each other, insufficient combination of silk and silk, and mutual detachment of silk from each other, etc. , to achieve the effect that it is not easy to separate from each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

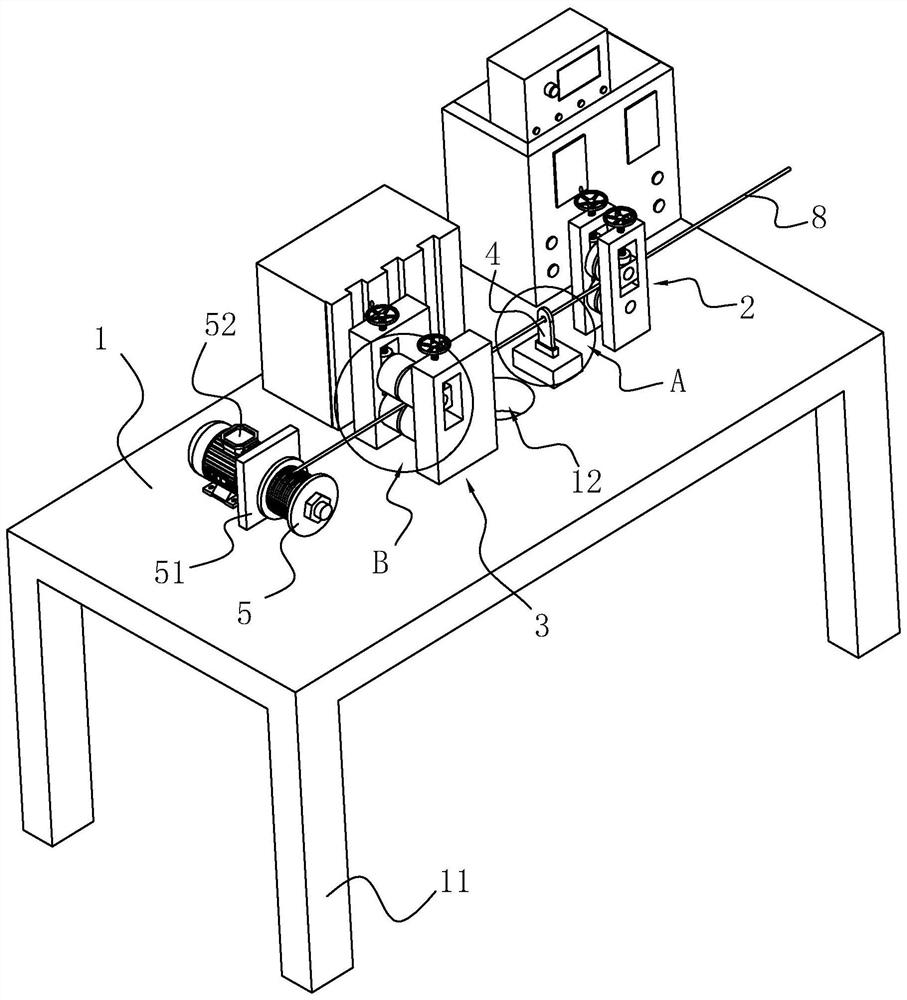

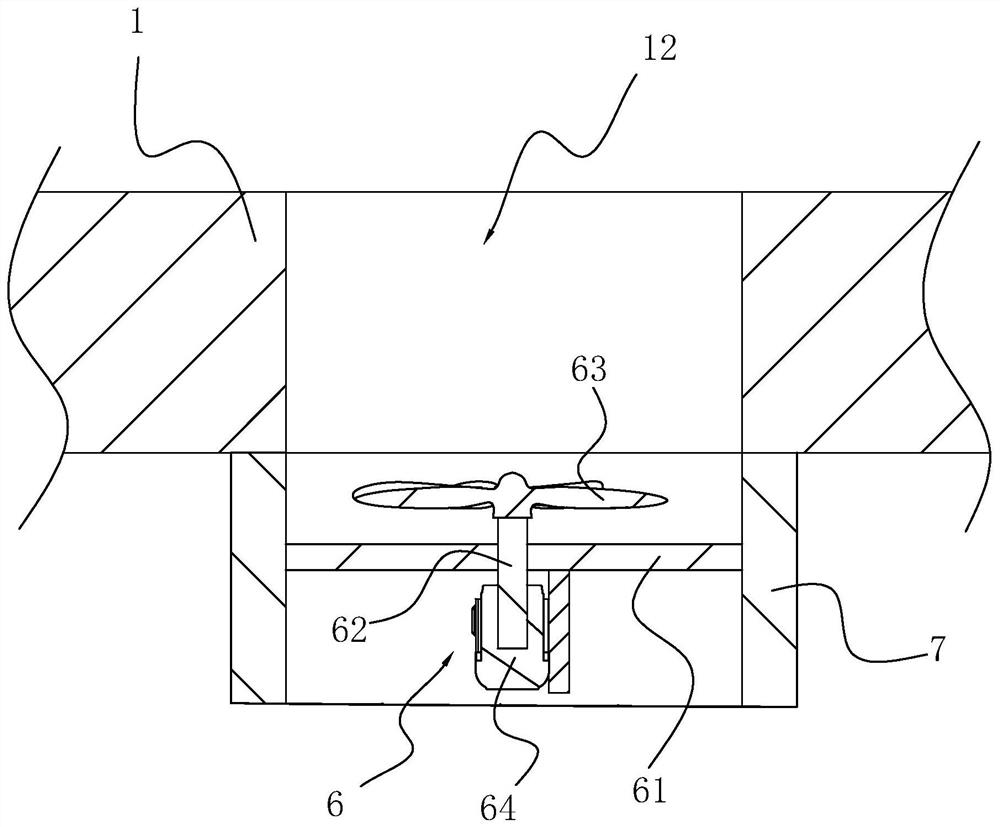

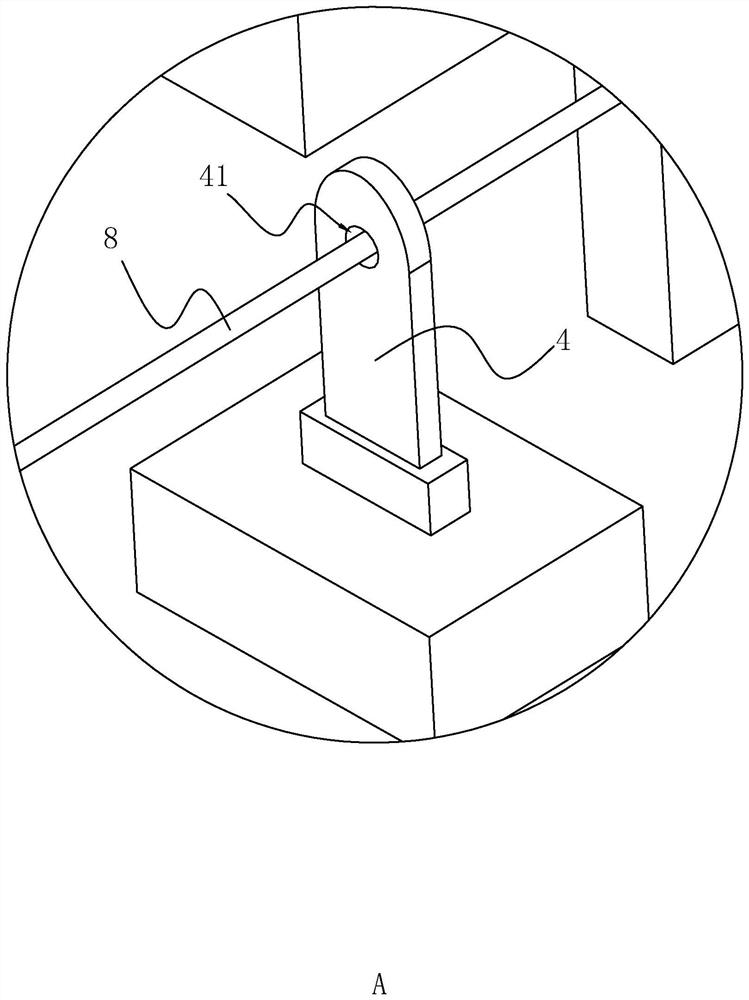

[0040] Embodiment 1: A kind of production equipment of roasted drawstring, refer to attached figure 1 And attached figure 2 , including a support plate 1 arranged in a rectangular shape, legs 11 fixedly connected to the four corners of the bottom of the support plate 1 for supporting the support plate 1, a feed roller set 2 and a discharge roller set 3 arranged on the support plate 1 , the heating sheet 4 that is arranged on the support plate 1 between the feed roller group 2 and the discharge roller group 3, the blowing fan 6 that is arranged on the support plate 1 and is located between the support sheet and the discharge roller group 3 and is arranged on The receiving roller 5 on the support frame is located on the side of the discharging roller group 3 away from the blowing fan 6 . The support plate 1 is fixedly connected with a vertically arranged fixed plate 51, the receiving roller 5 is rotatably connected to the fixed plate 51, and the side of the fixed plate 51 away...

Embodiment 2

[0047] Embodiment two: a kind of baking drawstring production process comprises the following steps:

[0048] a. Material selection: Select qualified plastic rope 8 as the raw material for production;

[0049] b. Heating: heating the surface of the plastic rope 8 to make the surface of the raw material melt, the temperature is controlled at 200°C during heating, and the transmission speed of the plastic rope 8 is 0.5m / s;

[0050] c. Cooling: Cooling the heated plastic rope 8 by air blowing, so that the melted part solidifies on the surface of the plastic rope 8 to form a roasted drawstring;

[0051] d. Winding: Roll the finished grilled drawstring together.

Embodiment 3

[0052] Embodiment three: a kind of roasting drawstring production process, comprises the following steps:

[0053] a. Material selection: Select qualified plastic rope 8 as the raw material for production;

[0054] b. Heating: heating the surface of the plastic rope 8, so that the surface of the raw material melts, the temperature is controlled at 225°C during heating, and the transmission speed of the plastic rope 8 is 0.5m / s;

[0055] c. Cooling: Cooling the heated plastic rope 8 by air blowing, so that the melted part solidifies on the surface of the plastic rope 8 to form a roasted drawstring;

[0056] d. Winding: Roll the finished grilled drawstring together.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap