Method and production line for processing of sweet potato noodles

A processing method and production line technology, applied in the direction of chemical instruments and methods, dissolution, food ingredients as taste improvers, etc., can solve the problems of poor cohesion of starch slurry, high operating intensity of employees, and easy breakage, so as to achieve fine and smooth taste and improve The effect of low production efficiency and breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

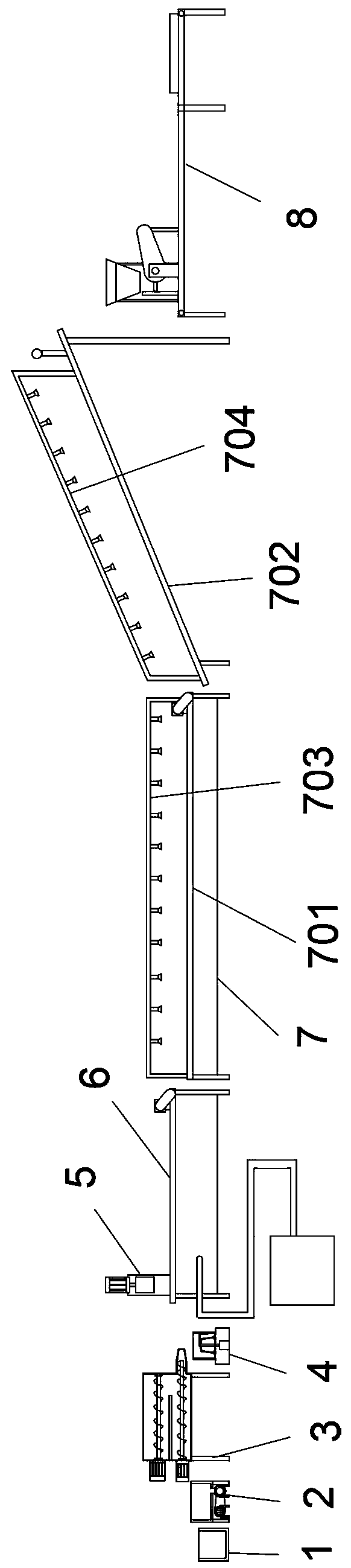

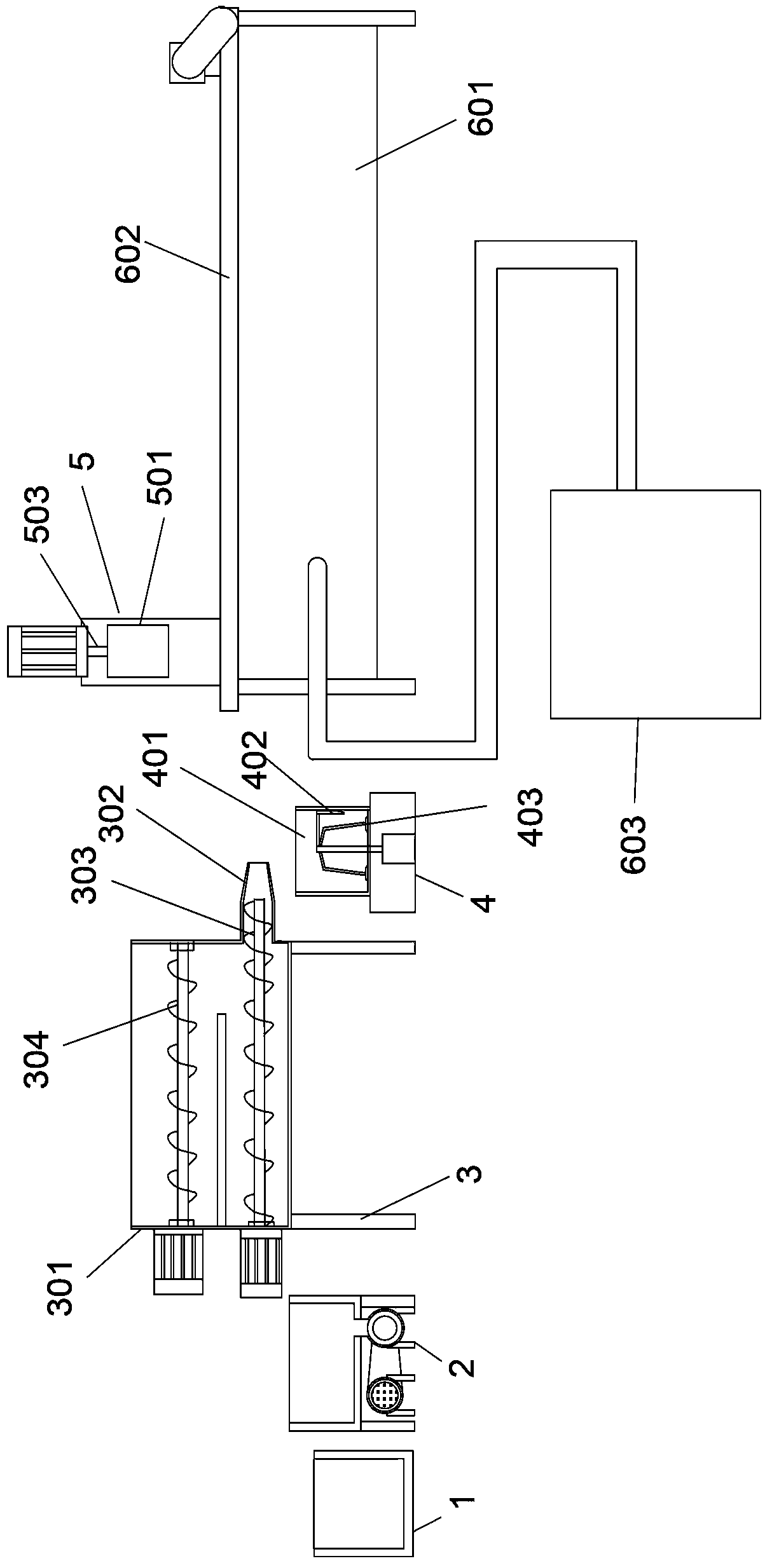

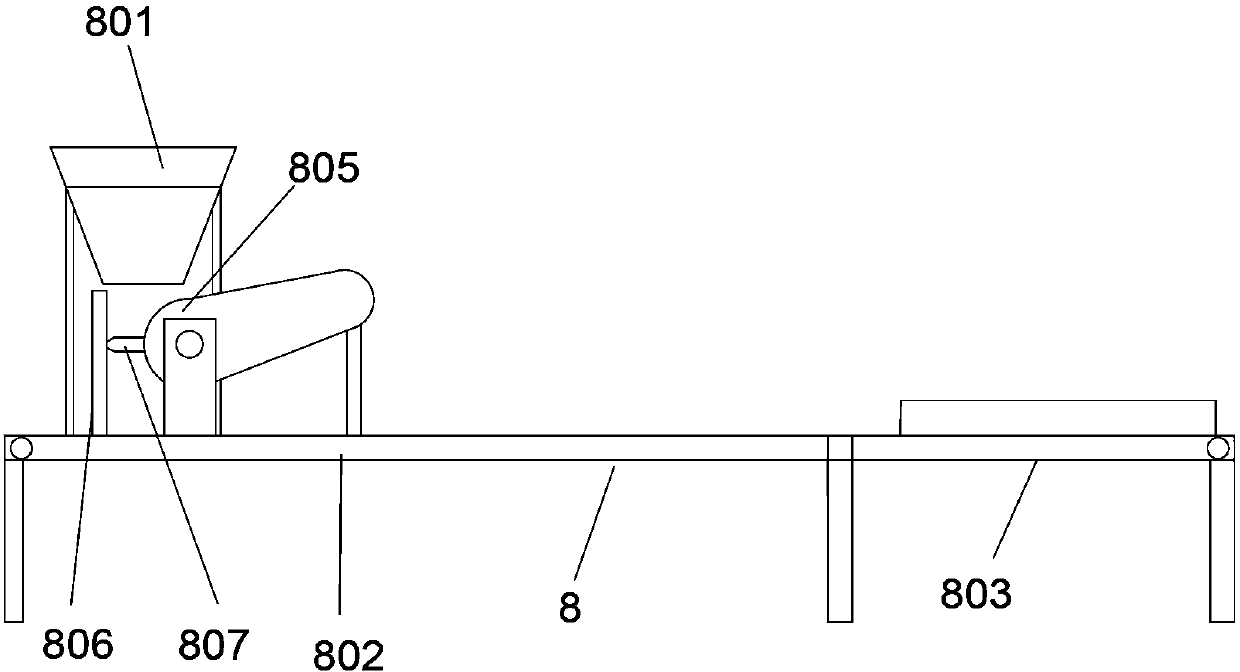

[0043] Now in conjunction with accompanying drawing, the present invention will be further described:

[0044] A kind of sweet potato noodle processing method described in the present embodiment, comprises the following steps:

[0045] (1) Soaking: Soak the dry sweet potato starch in the soaking bucket 1, make it absorb water and naturally precipitate to form sweet potato starch lumps;

[0046] (2) Preparation of starch slurry: take out the wet sweet potato starch lumps and put them into the starch mixer 2, control the temperature in the starch mixer 2 to 40°C, make it preheat while stirring to form the starch slurry, and extrude the starch after stirring for 60 minutes pulp;

[0047] (3) Prepare initial mix: according to the weight percentages of each component of raw materials: starch slurry 79.96%, cassava flour 19.99%, alum 0.05% takes by weighing raw materials, wherein cassava flour, alum are as auxiliary materials, starch slurry and auxiliary materials are added to auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com