Torsional vibration damper

A technology of torsional vibration dampers and components, applied in the field of torsional vibration dampers, can solve the problems of insecurity, lack of lubricating properties, high wear, etc., and achieve the effect of reliable and durable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

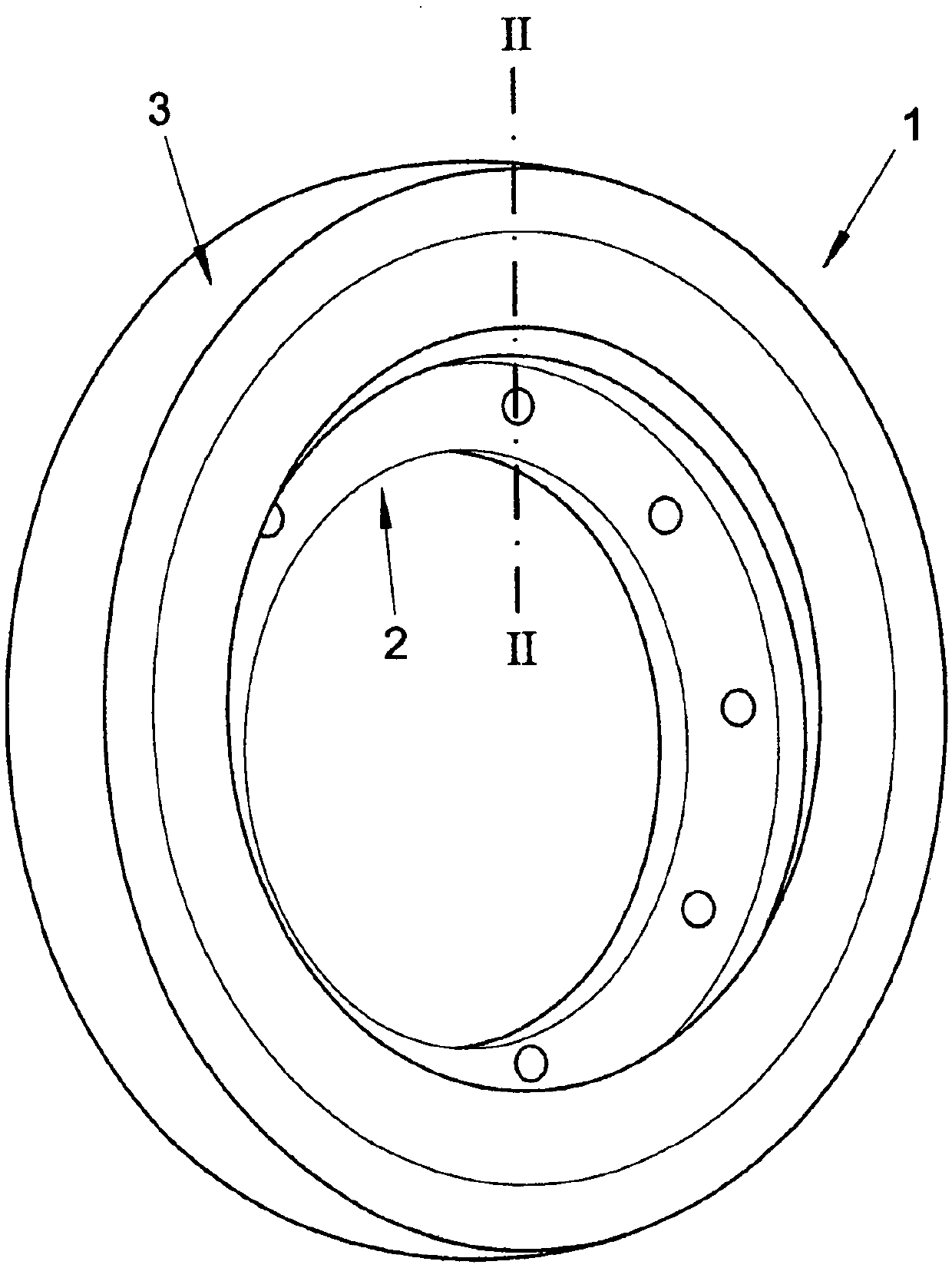

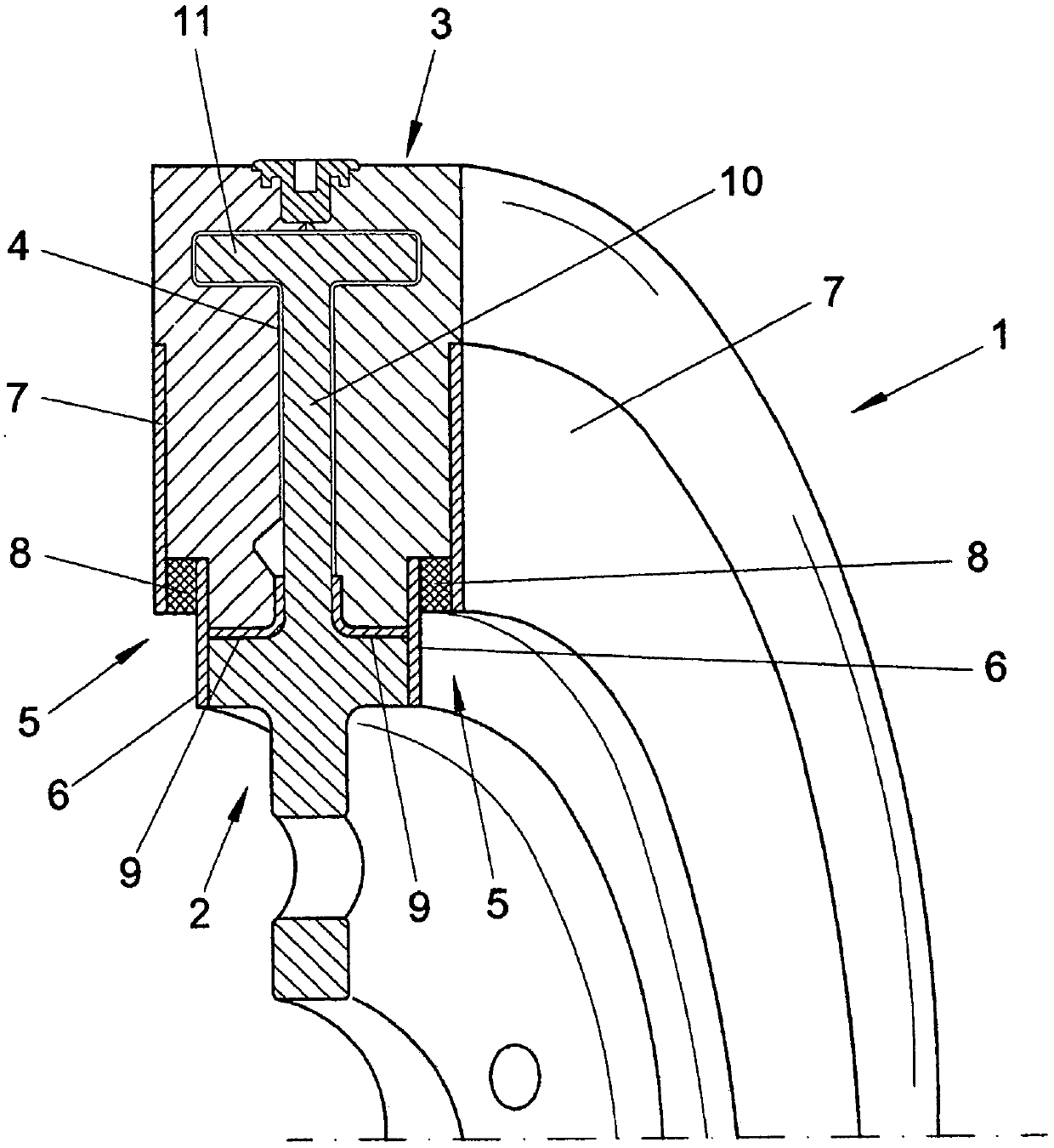

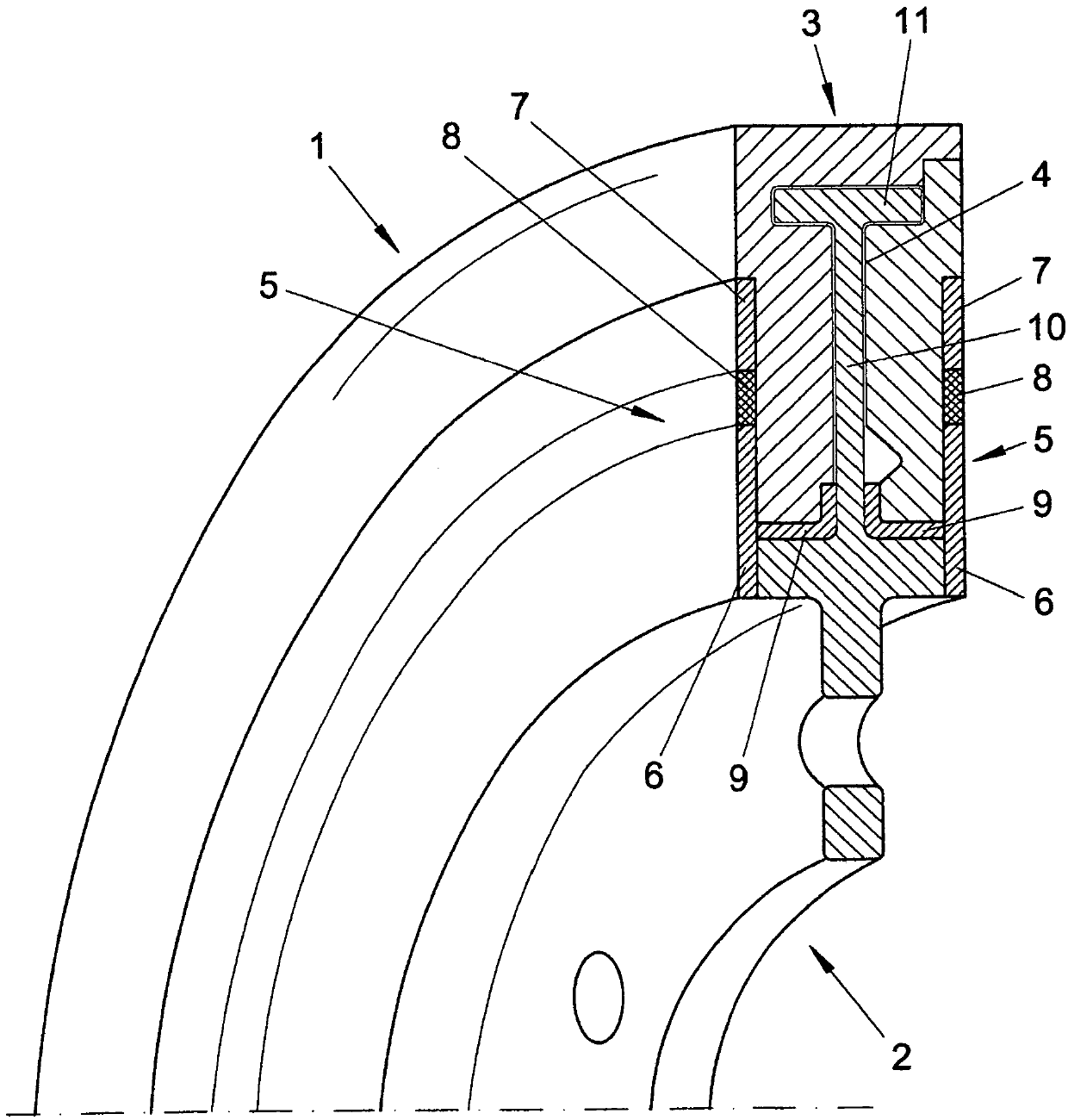

[0022] exist figure 1 and figure 2 The torsional vibration damper shown in and generally designated by the reference numeral 1 has a hub part 2 which can be fixed on the engine drive shaft and a flywheel ring 3 which surrounds said hub part 2 in the radially outer region, so The hub part may also be referred to as primary mass and the flywheel ring may also be referred to as secondary mass.

[0023] Between the hub part 2 and the flywheel ring 3 there is a gap 4 which is filled with a fluid, preferably silicone oil. The area of the gap 4 is sealed outwards by a sealing means 5 which will be described in more detail below.

[0024] Each sealing device 5 comprises, respectively: a first ring 6 sealingly connected to the hub part 2; a second ring 7 also sealingly connected to the freewheel ring 3; and a ring 8 made of elastomer, which On the one hand, it is tightly connected to the first ring 6 and on the other side to the second ring 7 .

[0025] The respective first and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com