Generator end cover clamping device

A generator end and cover clamp technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of fixed operation, complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

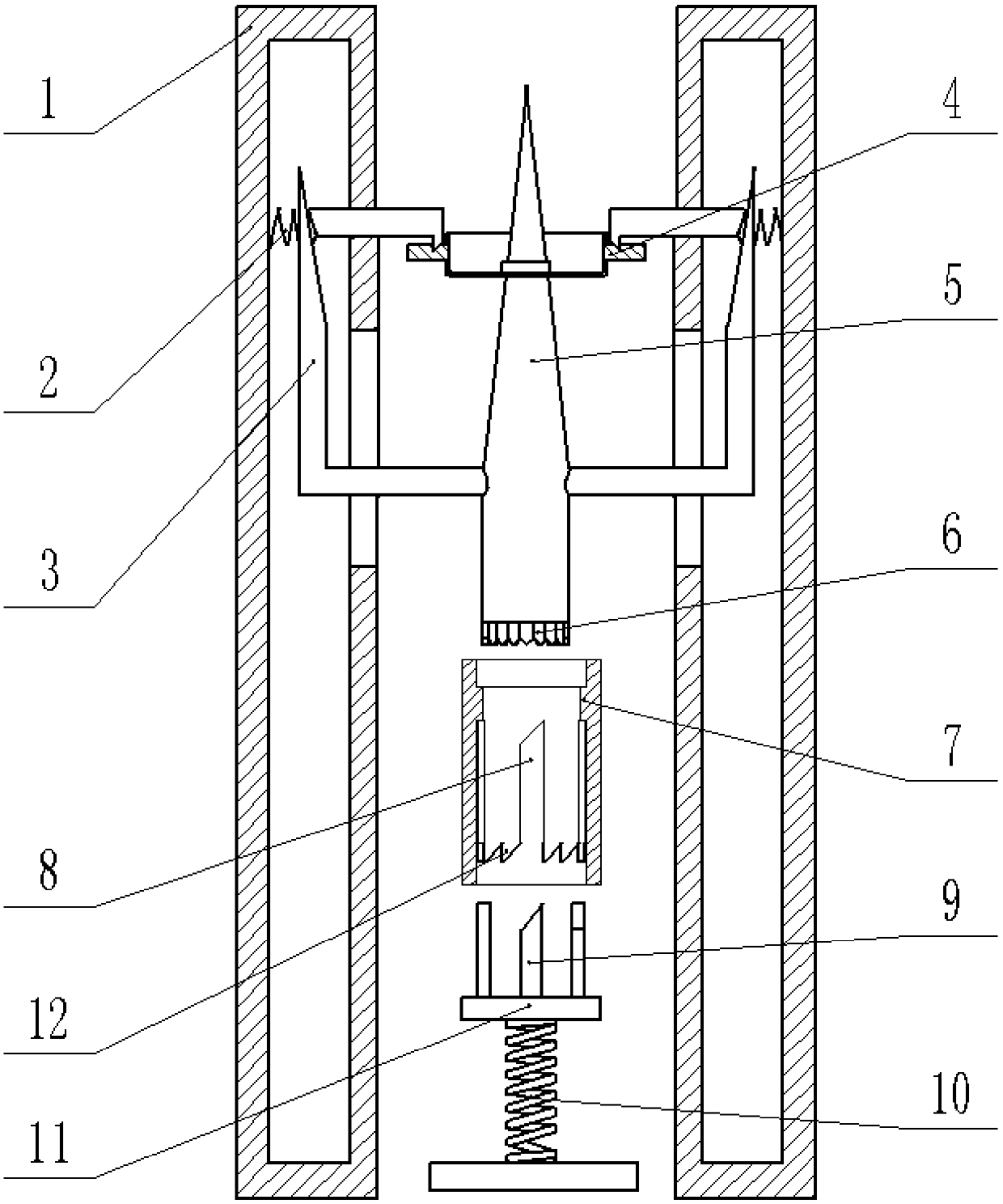

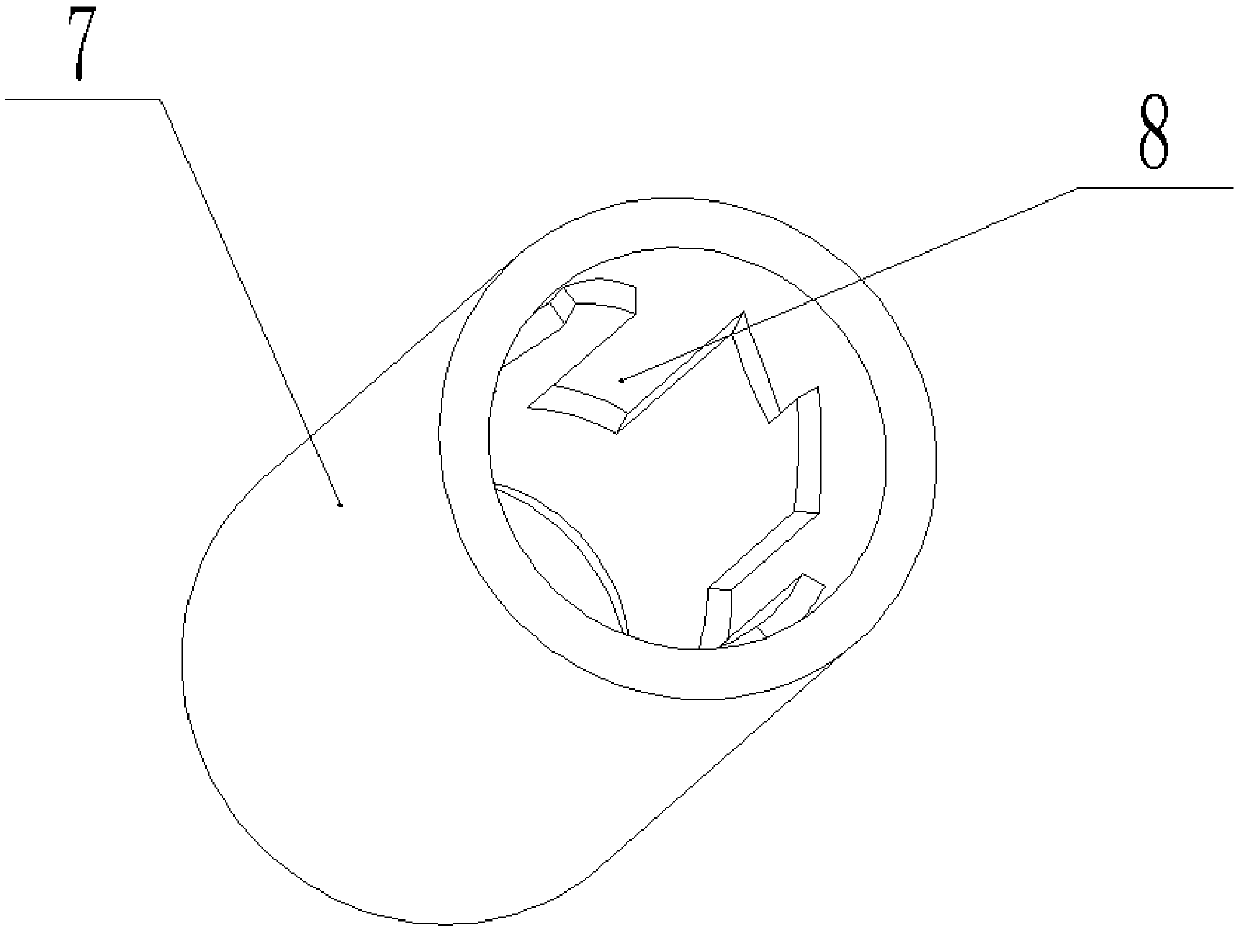

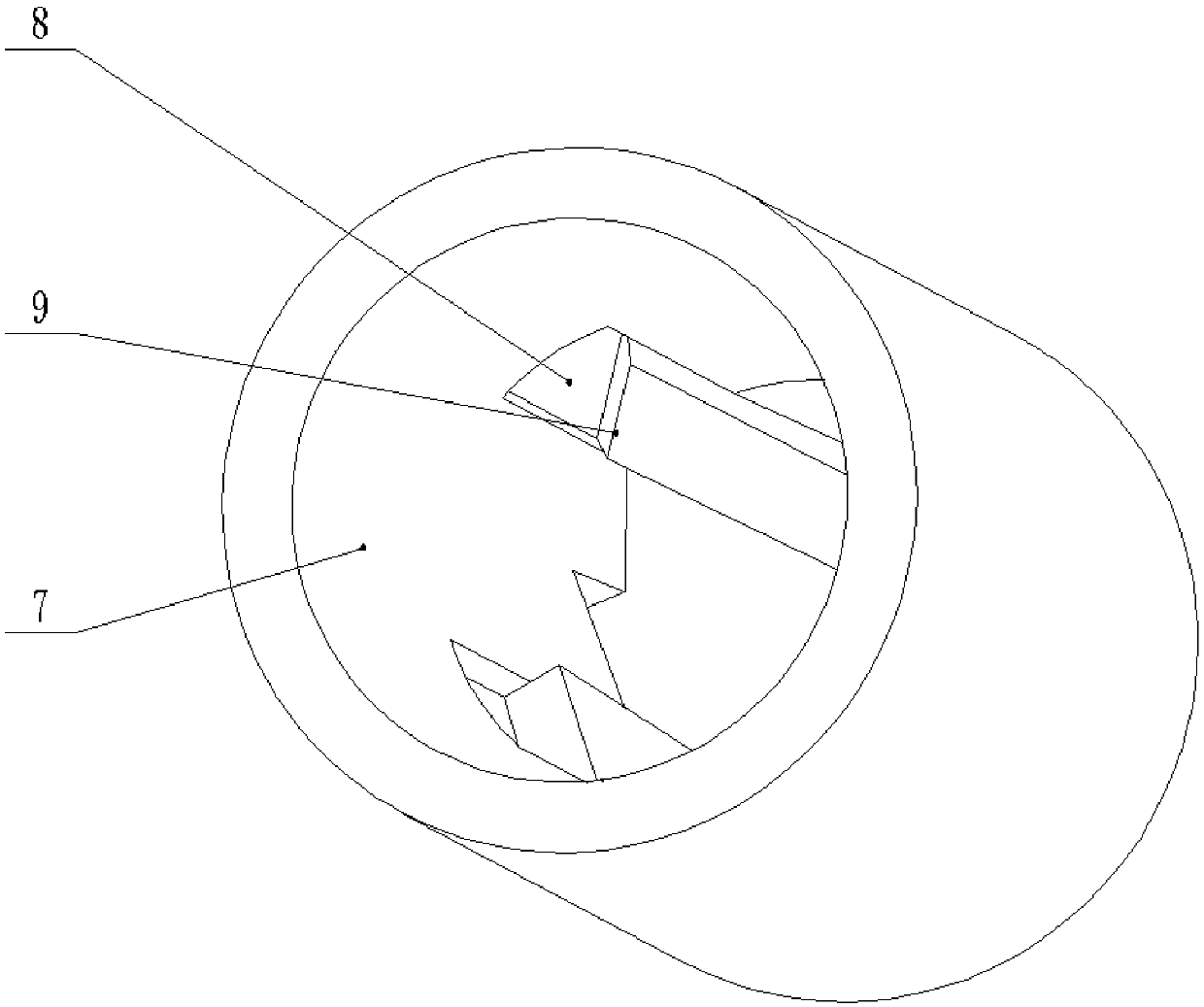

[0024] The reference signs in the drawings of the specification include: limit plate 1, second spring 2, limit rod 3, generator end cover 4, support column 5, push claw 6, support cylinder 7, slideway 8, slide claw 9 , The first spring 10, the support plate 11, the wedge 12.

[0025] The generator cover clamping device includes a base, a support mechanism, a reset mechanism and a limit mechanism.

[0026] as combined figure 1 , figure 2 and image 3 As shown, the base includes a base, and a support cylinder 7 is fixedly connected above the base. The support cylinder 7 is a cylinder, and the axis of the support cylinder 7 is perpendicular to the plane of the base. The inner wall of the support cylinder 7 is provided with slideways 8, the number of slideways 8 is four, the slideways 8 are evenly arrayed in the circumferential direction of the support cylinder 7, and the sliding di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com