Lapping machine

A lapping machine and frame technology, applied in the field of lapping machines, can solve problems such as troubles and affecting processing efficiency, and achieve the effect of simplifying the operation process, improving processing efficiency, and reducing the possibility of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

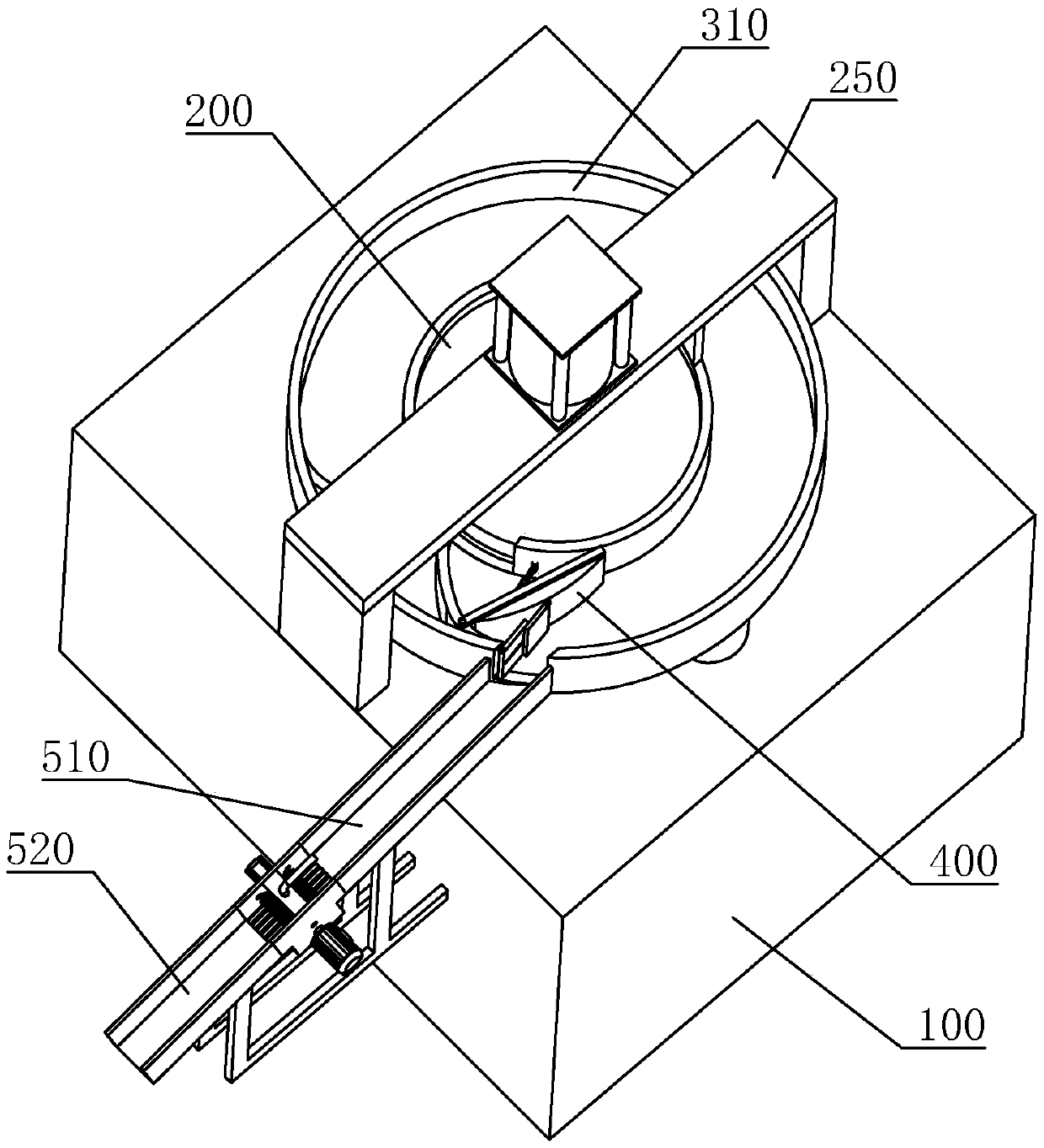

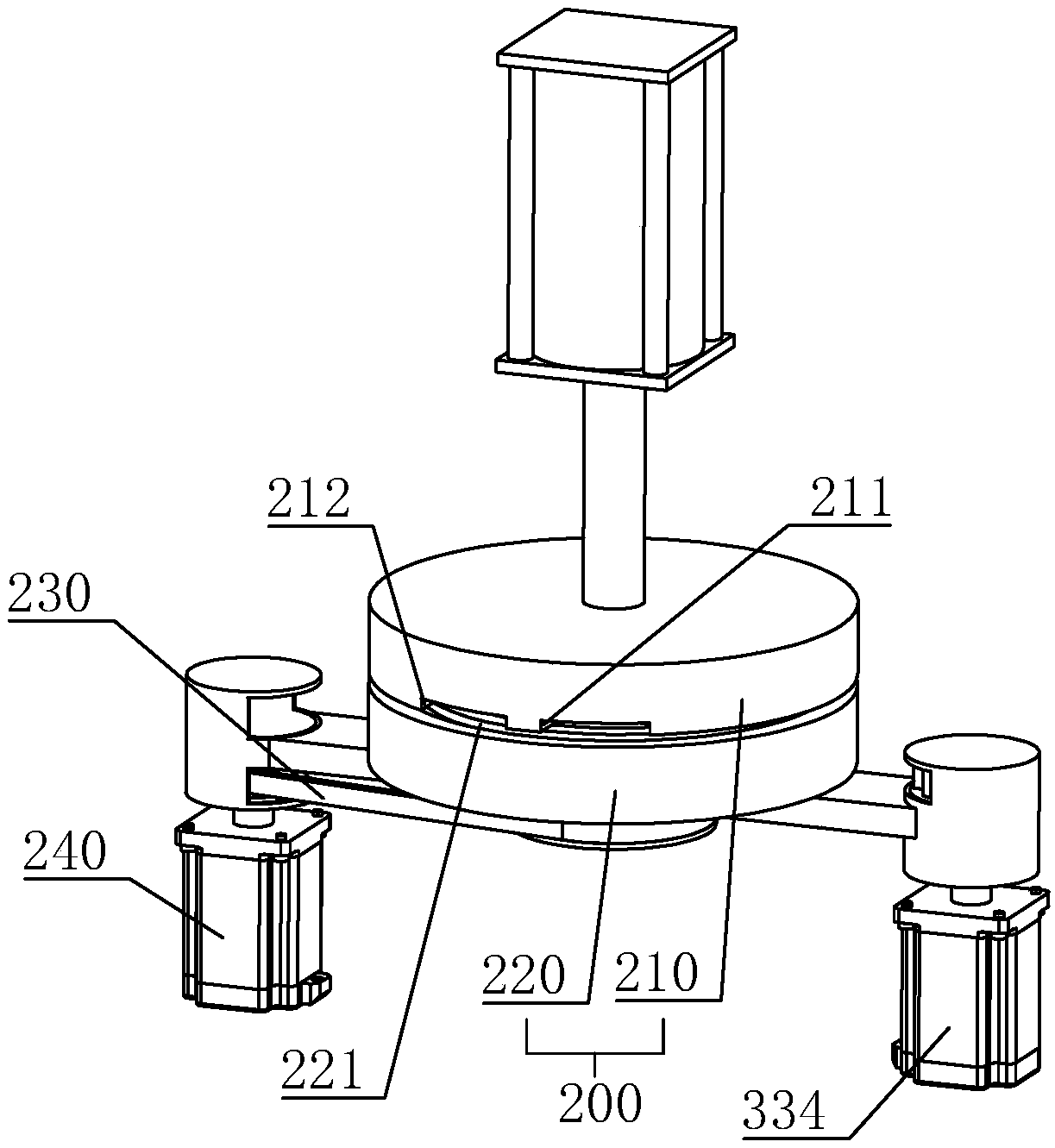

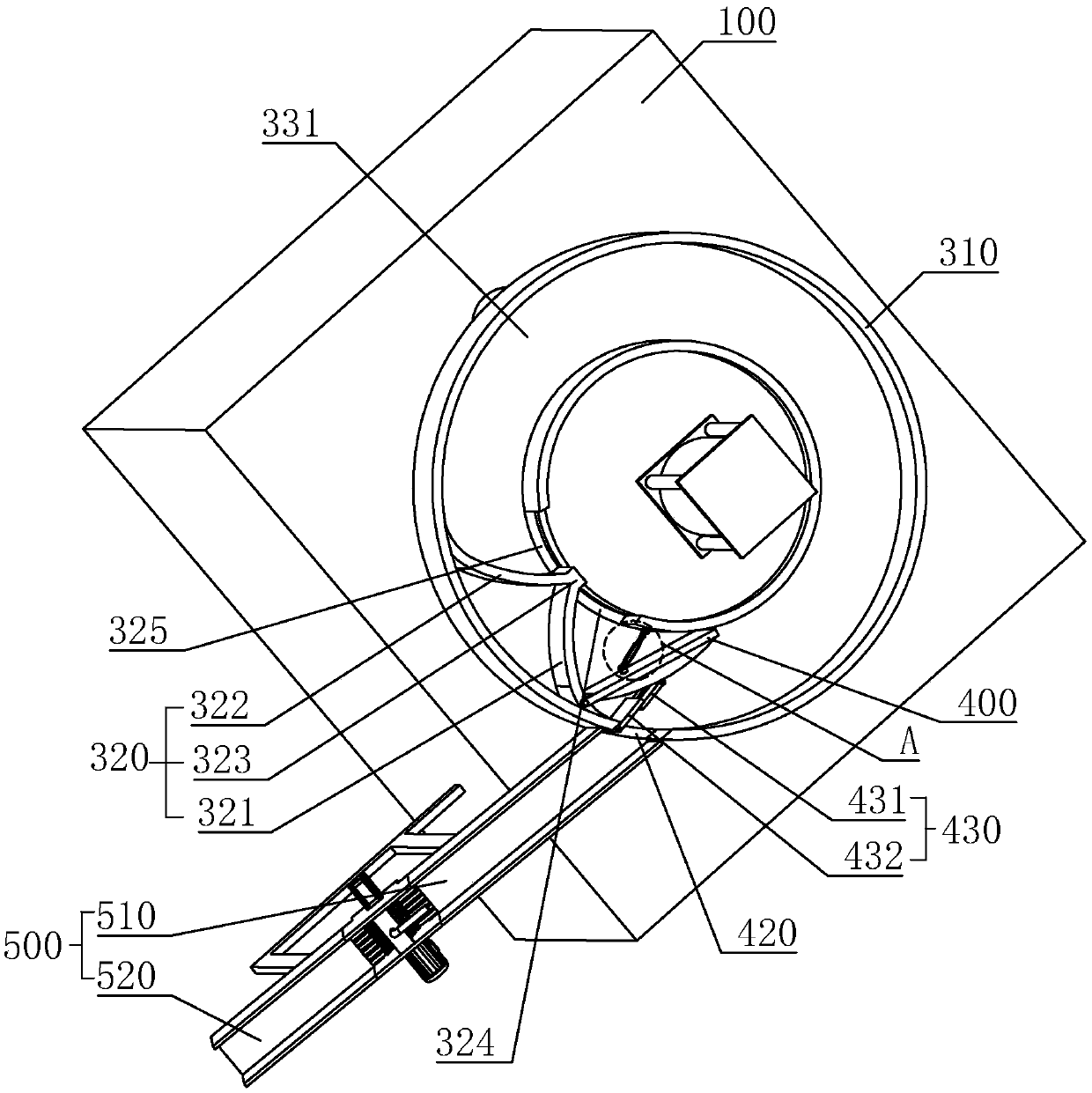

[0041] A lapping machine, comprising a frame 100, a grinding structure 200 is arranged on the frame 100, the grinding structure 200 includes an upper grinding disc 210 and a lower grinding disc 220, the lower grinding disc 220 is rotatably connected to the Several concentric grinding ring grooves 221 are provided on the upper and lower grinding discs 220 of the frame 100 . A grinding motor 240 is fixed on the frame 100 by bolts, and the grinding motor 240 drives the first rotating shaft to rotate through the first belt 230 . The upper grinding disc 210 is fixedly installed above the lower grinding disc 220 through a bracket. A feed channel 211 and a discharge channel 212 are opened on the edge of the upper grinding disc 210 along its radial direction.

[0042] An annular feeding channel 310 is welded on the frame 100 , and the grinding structure 200 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com