Rotary equipment rolling ring and riding wheel self turning device

A rolling ring and supporting wheel technology, which is applied in turning equipment, turning equipment, metal processing equipment, etc., can solve problems such as increased runout, unstable operation of equipment, and accelerated wear speed of grinding blocks, and achieves accurate and precise position adjustment , Convenient and fast repair processing, the effect of precision requirement restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

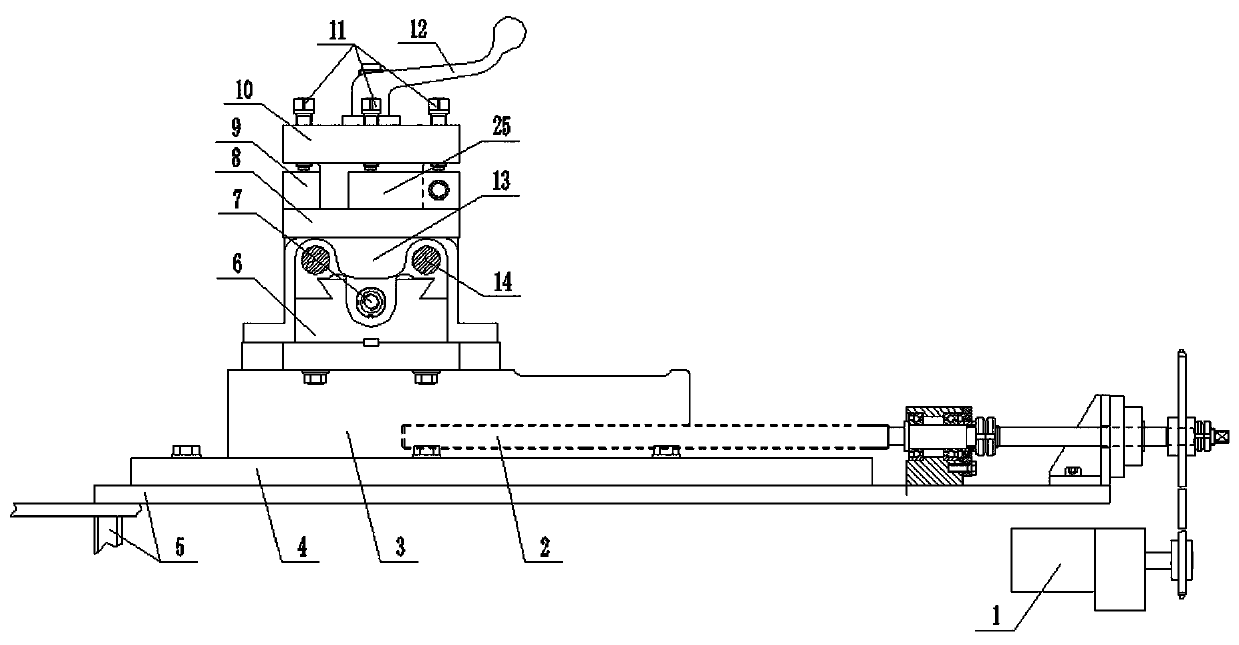

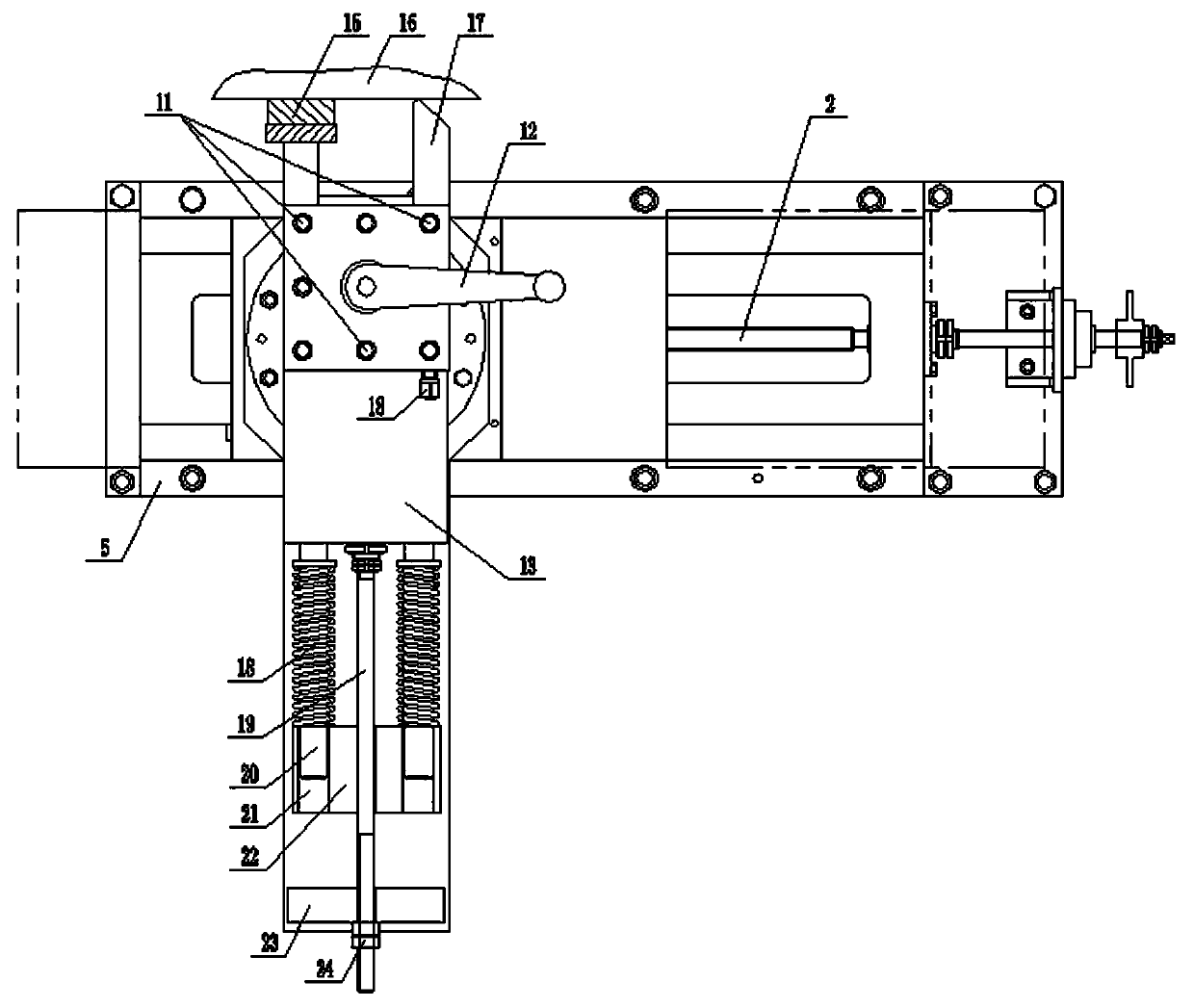

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 with figure 2 Shown, the present invention comprises frame 5, is provided with the longitudinal slide rail 4 that is arranged along the left and right direction on frame 5 top, is connected with longitudinal sliding seat 3 on longitudinal sliding rail 4, is fixed on longitudinal sliding seat 3 along The transverse slide rail 6 arranged in the front and back directions is slidably connected with a transverse slide seat 13 on the transverse slide rail 6, and a self-calibrating circle turning mechanism is fixed on the transverse slide seat 13; The power lead screw 2 that slides left and right on the rail 3 is fixed with a motor 1 for driving the power lead screw 2 to rotate on the frame 5 .

[0014] The self-calibrating circle turning mechanism includes a bottom plate 8 and a top plate 10, the bottom plate 8 is fixed on a transverse slide 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com