Early warning method for generator overheating fault hidden danger based on three-dimensional display

A three-dimensional display, generator technology, used in motor generator testing, heat measurement, thermometer application, etc., can solve the problems of inability to discharge water and coil temperature measurement point number, analysis lag, inability to distinguish between operators, etc., to achieve good technology Supported Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with examples. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

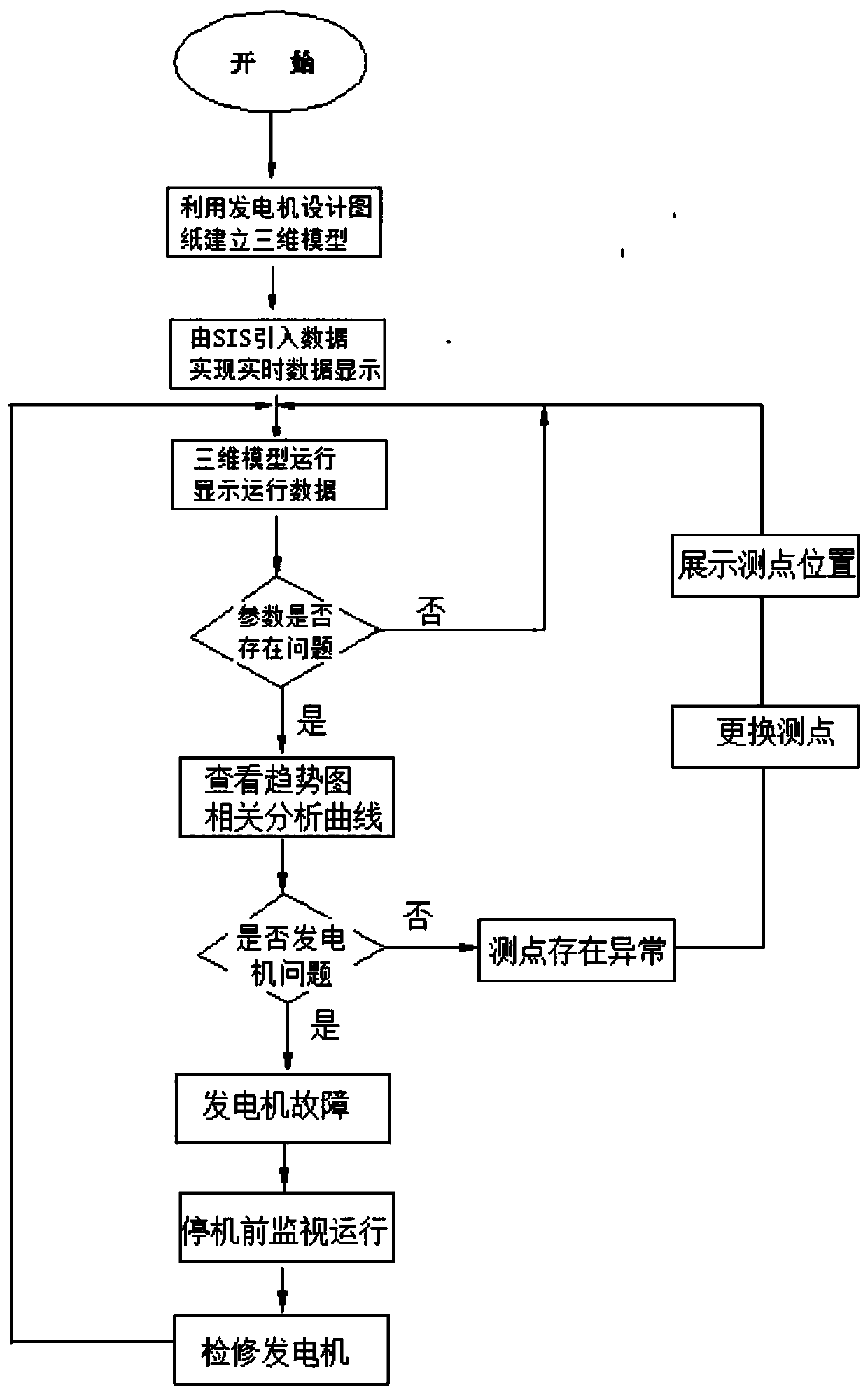

[0022] The present invention is based on the three-dimensional display of the generator overheating failure hidden danger warning process as follows: figure 1 Shown: including the following steps:

[0023] (1) Use the generator design drawings to establish a three-dimensional model of the generator. The parts displayed by the three-dimensional model of the generator include the generator rotor, stator, coil, coil slot and the upper and lower water outlets of the slot. The three-dimensional model of the generator also includes the parameter display of related systems, including hydrogen system, stator cooling water system and sealing oil system.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com