A Bolt-Actuated Sniper Rifle Launching Mechanism Without Bolt

A firing mechanism and rifle technology, applied in the field of firearms, to achieve the effects of improving shooting comfort, improving ergonomics, and preventing accidental firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

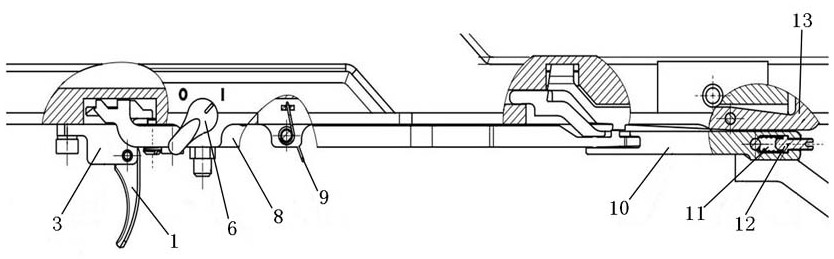

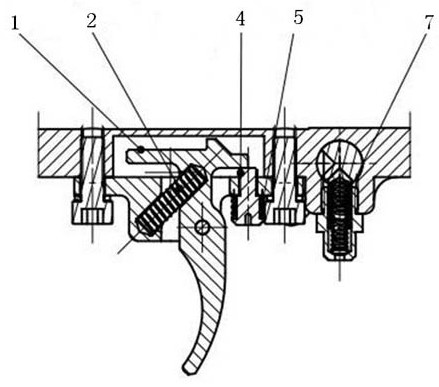

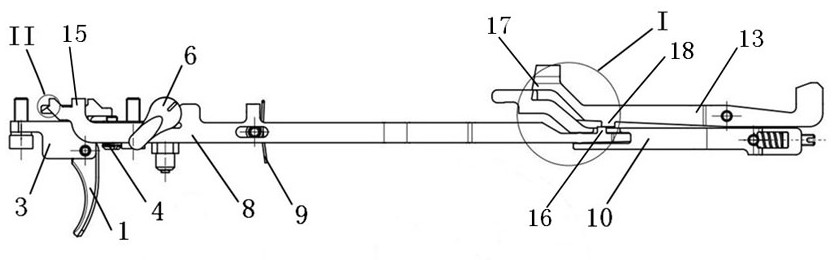

[0032] Such as Figure 1 to Figure 7As shown, the firing mechanism of a sniper rifle without a support bolt in this embodiment is characterized in that it includes a trigger 1, a trigger spring 2, a trigger seat 3, a connecting rod 8, a connecting rod spring 9, a firing rod 10, and a firing rod spring 11 and sear 13; the inner chamber of the trigger seat 3 is horizontally fixed with a trigger shaft; the trigger 1 is empty on the trigger shaft; the two ends of the trigger spring 2 are respectively in contact with the trigger 1 and the trigger seat 3; The side of the connecting rod 8 is provided with an elliptical through hole; a horizontally fixed connecting rod shaft passes through the elliptical through hole; the connecting rod spring 9 is sleeved on the connecting rod shaft and connected with the connecting rod 8 The front end of the connecting rod 8 is provided with a first boss 15; the top of the trigger 1 is provided with a first groove; the first boss 15 is located in th...

Embodiment 3

[0039] On the basis of above-mentioned embodiment, propose embodiment 3, as Figure 1 to Figure 3 As shown, it is characterized in that: the actuating sniper rifle firing mechanism without a support bolt also includes a trigger adjustment screw 4 and a trigger adjustment screw spring 5; It conflicts with the lower surface of the upper rear end of the trigger 1; the two ends of the trigger adjusting screw spring 5 are respectively connected to the trigger base 3 and the trigger adjusting screw 4.

[0040] By screwing in and out of the trigger adjustment screw 4, the size of the idle stroke of the trigger 1 can be adjusted, thereby adjusting the overall firing stroke. The trigger adjustment screw spring 5 is used to prevent the trigger adjustment screw 4 from loosening.

Embodiment 4

[0042] On the basis of above-mentioned embodiment, propose embodiment 4, as figure 1 As shown, it is characterized in that: the firing mechanism of a sniper rifle without a bolt also includes a firing rod screw 12; the firing rod spring 11 is screwed and fixed by connecting the firing rod screw 12.

[0043] By screwing in and out of the firing rod screw 12, the tightness of the firing rod spring 11 can be adjusted, thereby adjusting the firing force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com