A fixture for positioning and pasting strain gauges on round rod members

A technology of strain gauges and components, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problems of inability to guarantee the symmetry of the patch position, low data measurement accuracy, and poor operation consistency, so as to facilitate installation and disassembly and avoid impact Accuracy, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

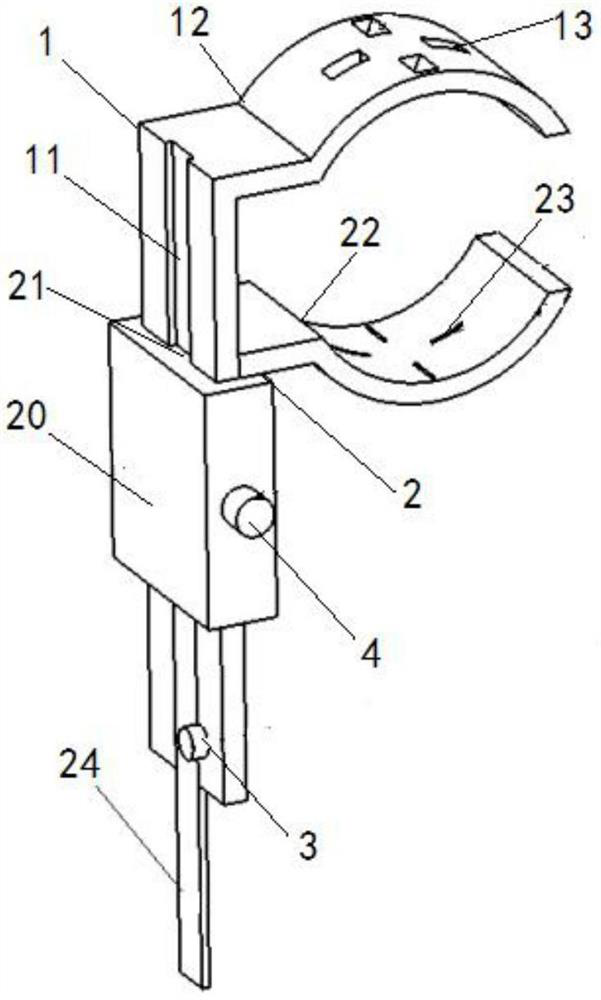

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

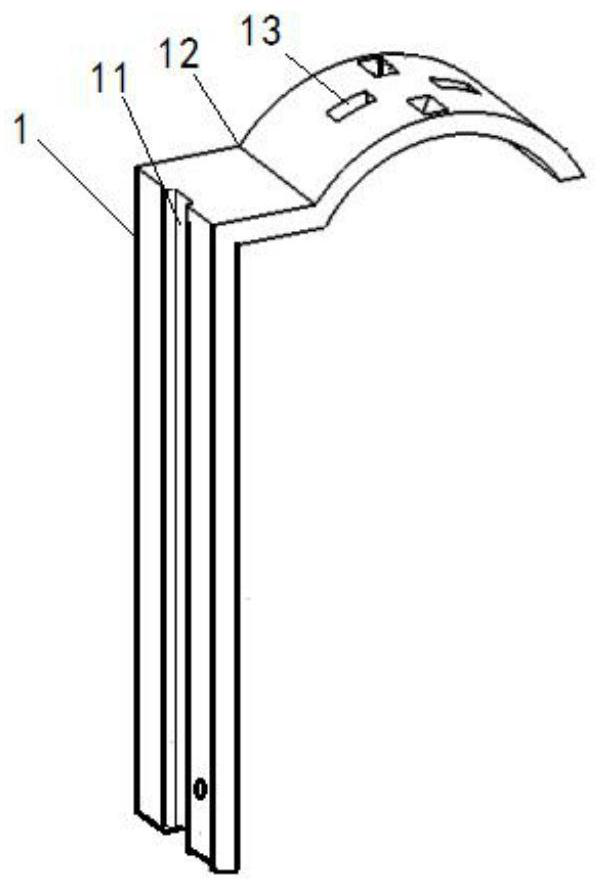

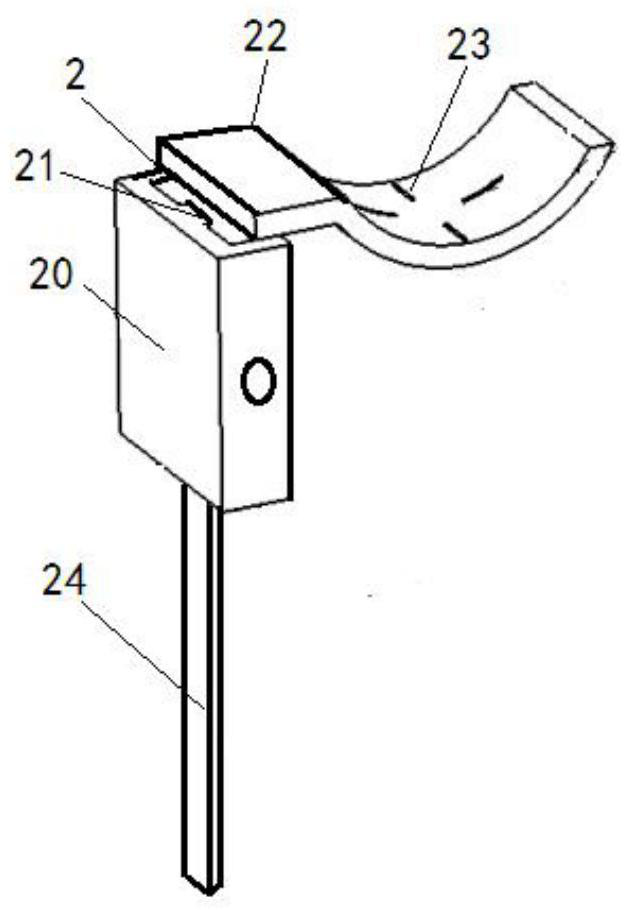

[0031] see figure 1 , figure 2 ,and image 3 The shown clamp for positioning and pasting strain gauges on a round bar member includes an upper clamping ruler 1 and a lower clamping ruler 2 matched therewith, and its features are:

[0032] The upper clamping ruler 1 is composed of a ruler part and an upper clamp 12 connected to the upper end of the ruler part; a through chute 11 is provided on the ruler part of the upper clamping ruler 1; the upper clamp 12 is composed of The straight part and the arc part connected to the right end are formed in a "sickle shape", and the straight part is vertically connected to the right side of the upper end of the ruler part, and the arc opening of the arc part is downward;

[0033] The lower clamping ruler 2 is composed of a sliding sleeve 20, a lower chuck 22 connected to the right part of the upper end of the sliding sleeve 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com