Intelligent feeding and discharging system with accurate positioning function for circuit board electroplating line

A technology for precise positioning and circuit boards, applied in the direction of electrolysis, electrolysis components, cells, etc., can solve the problems that the electroplating clamp cannot clamp the circuit board, affect the quality of circuit board plating, and the high rate of circuit board dropouts, etc., to reduce time, Effect of reducing impact and reducing board drop rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

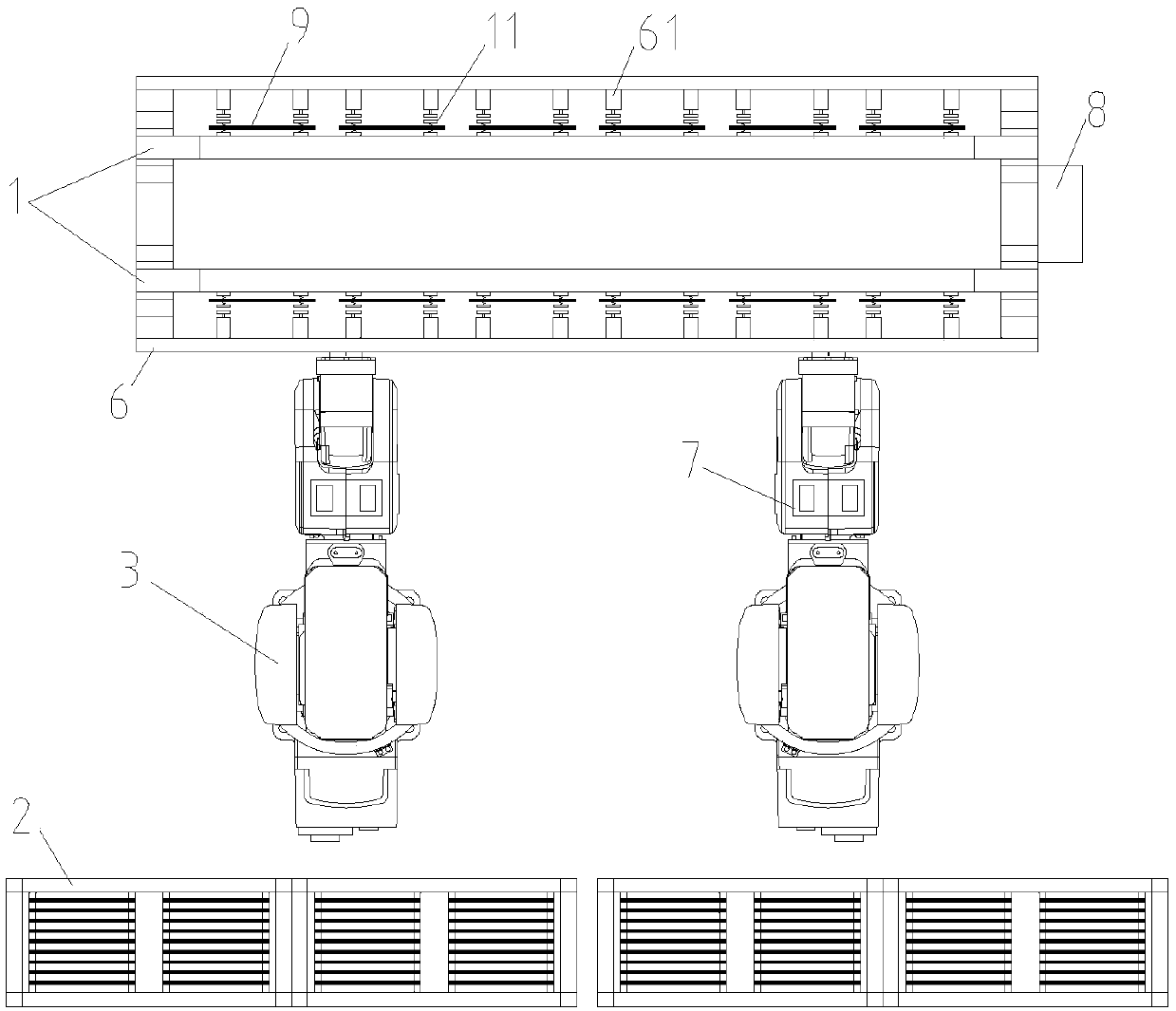

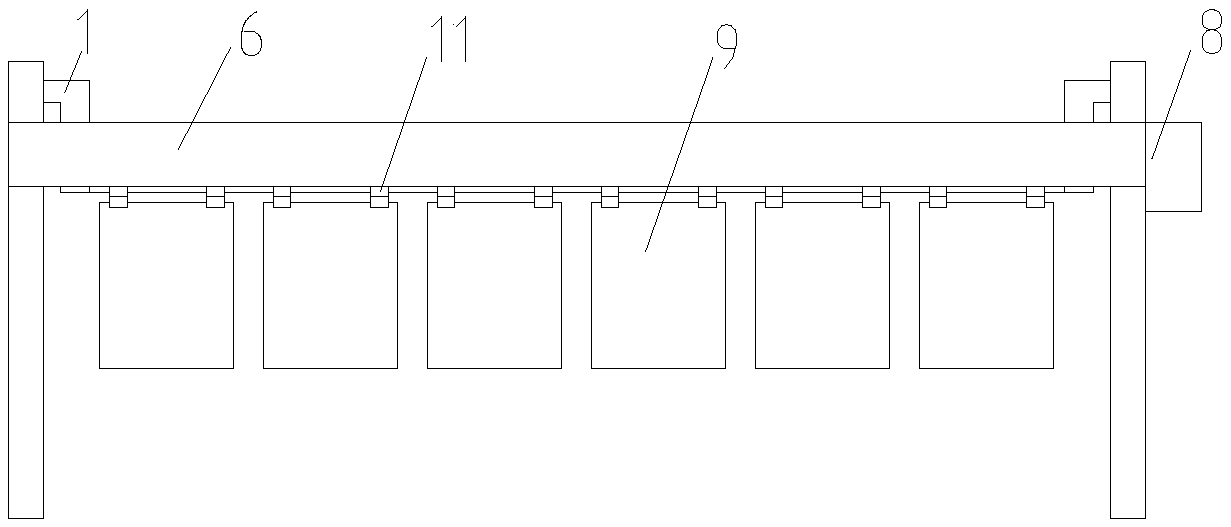

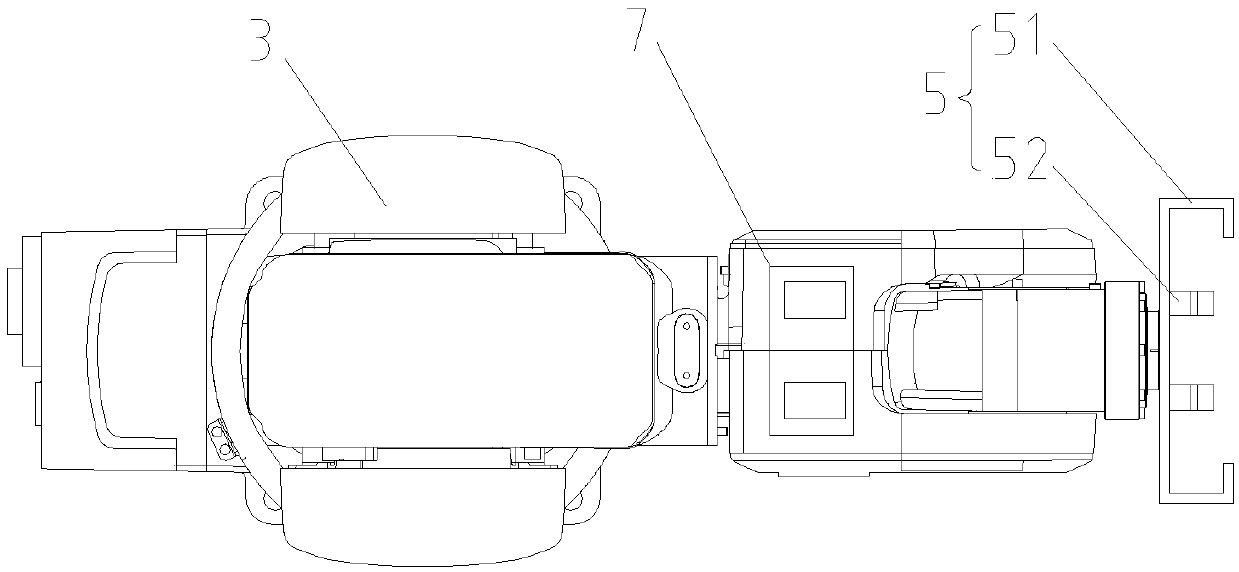

[0038] like Figure 1-7 As shown, the present invention discloses an intelligent loading and unloading system for a circuit board electroplating line that can be precisely positioned, including an electroplating flying bus 1, a board loading and unloading robot 3, a master controller 4, and a material frame 2 for placing circuit boards. Among them, the upper and lower plate robot 3 preferably adopts a six-axis robot. The six-axis robot is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com