A multifunctional screen printing machine

A screen printing machine, multi-functional technology, applied in the direction of screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of limited application range, high labor intensity, long printing cycle, etc., to expand the application field, expand The scope of application and the effect of flexible production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

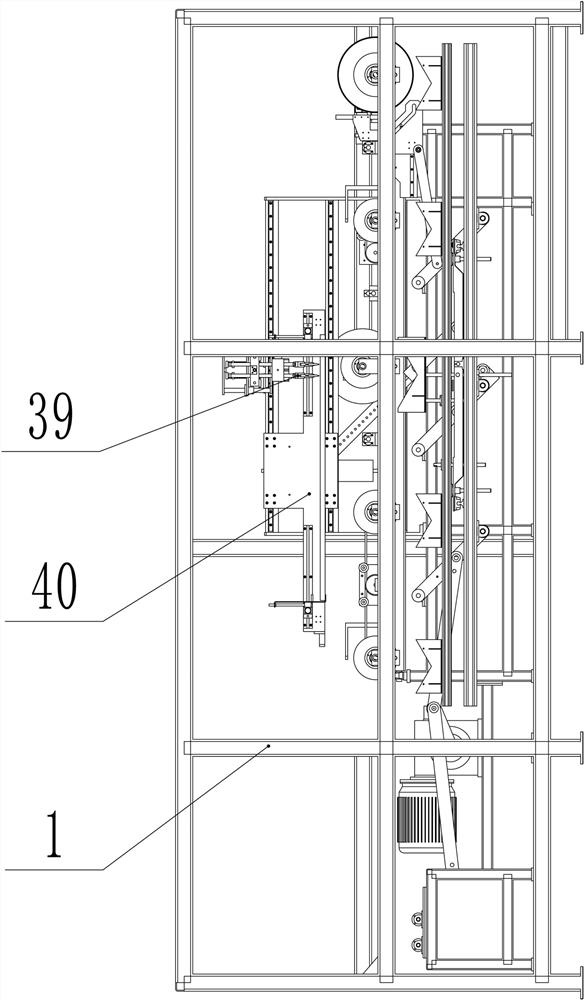

[0028] as attached figure 1 As shown, the present invention includes a frame-shaped frame 1, a station frame fixedly arranged on the frame 1, a swing frame that is connected to a driving device under the station frame and realizes transporting workpieces through reciprocating motion, and a station frame located at the station frame. Printing device above. At the same time, the feeding end of the frame 1 is provided with a feeding device, and the feeding end of the frame 1 is provided with a feeding conveying device. The unloading and conveying device can facilitate single-machine cycle work or multiple assembly-line production, and the configuration is more flexible.

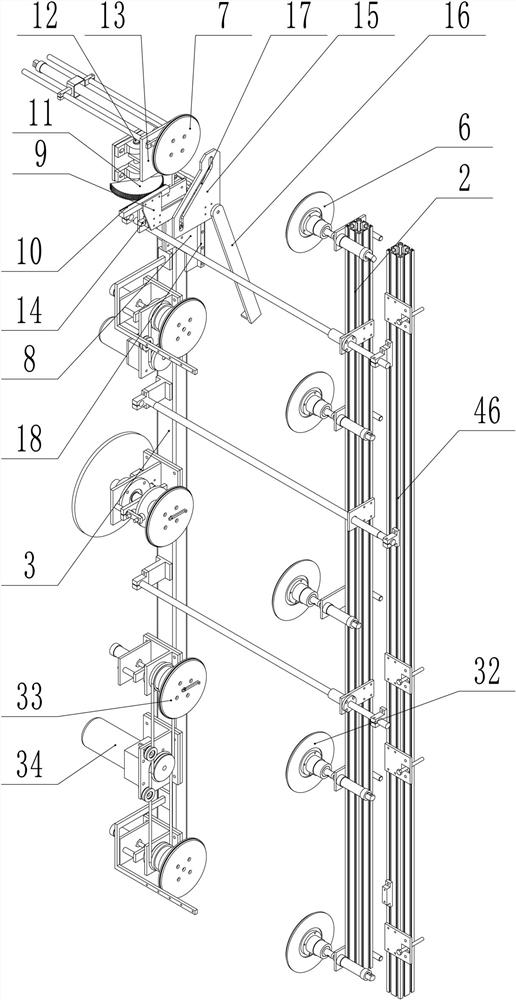

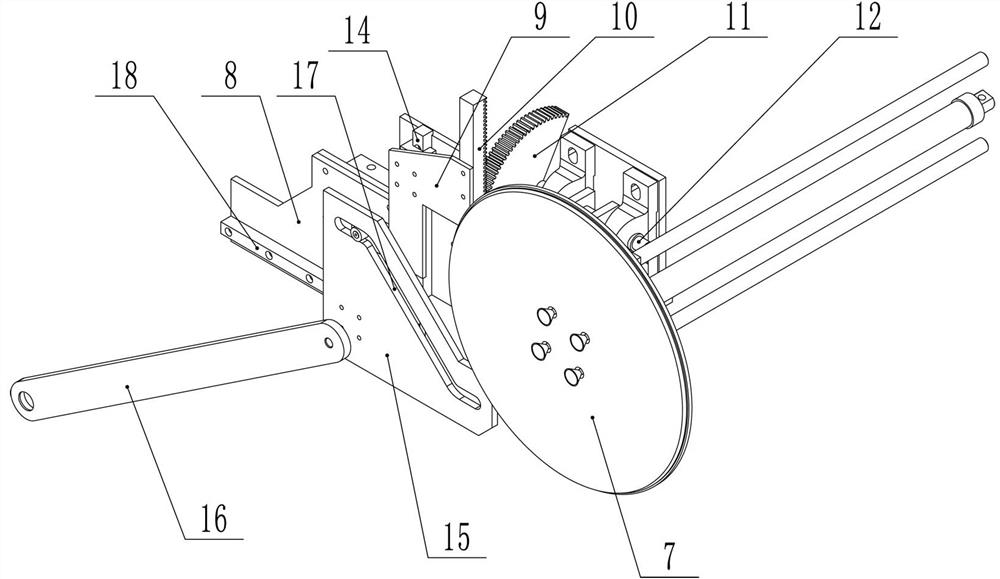

[0029] as attached figure 2 As shown, the station frame includes a front support 2 and a rear support 3 respectively located at both ends of the workpiece, and a processing station and a blanking station sequentially arranged on the front and rear supports. The rear support 3 is connected with the frame 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com