A Keyhole-less Friction Stir Spot Welding Machine

A friction stir and spot welding machine technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of less professional friction stir welding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

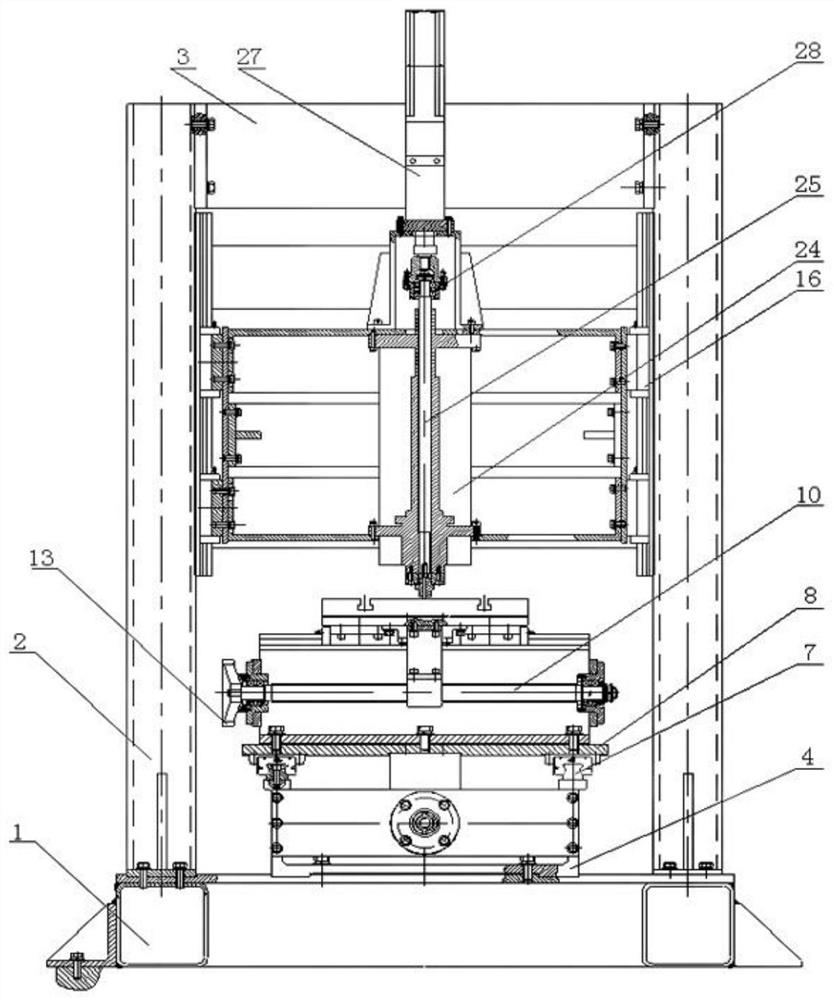

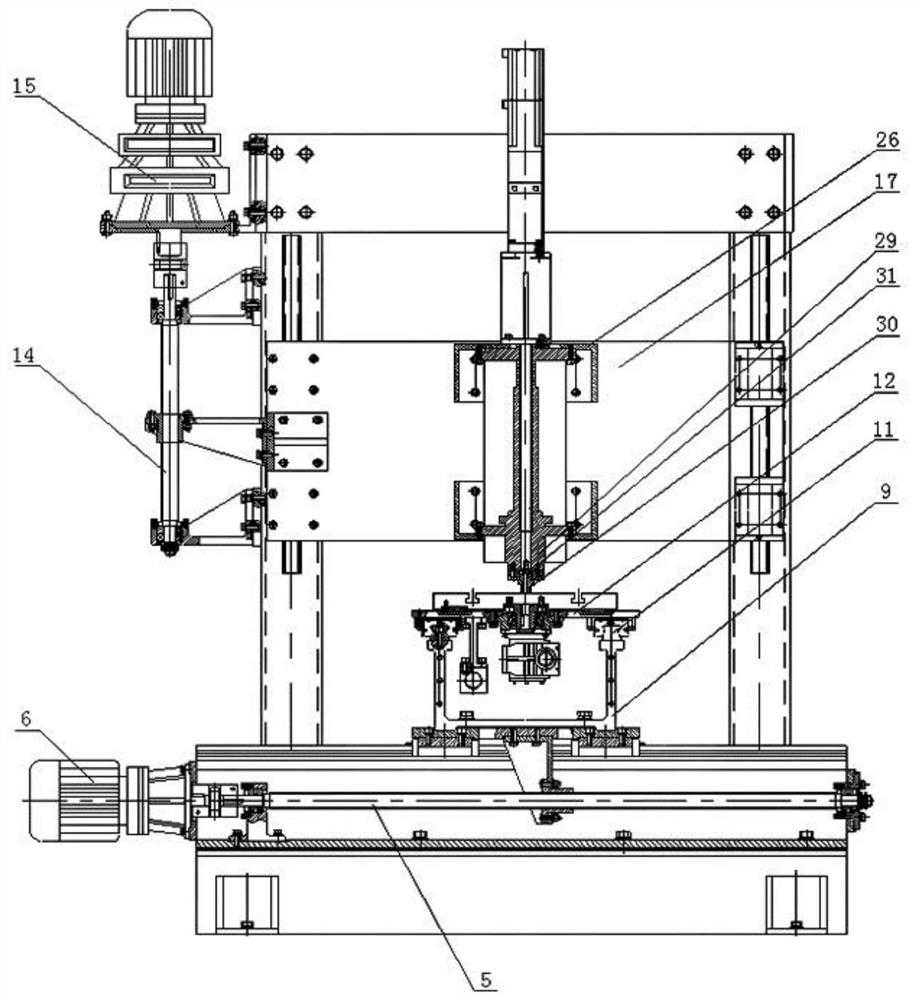

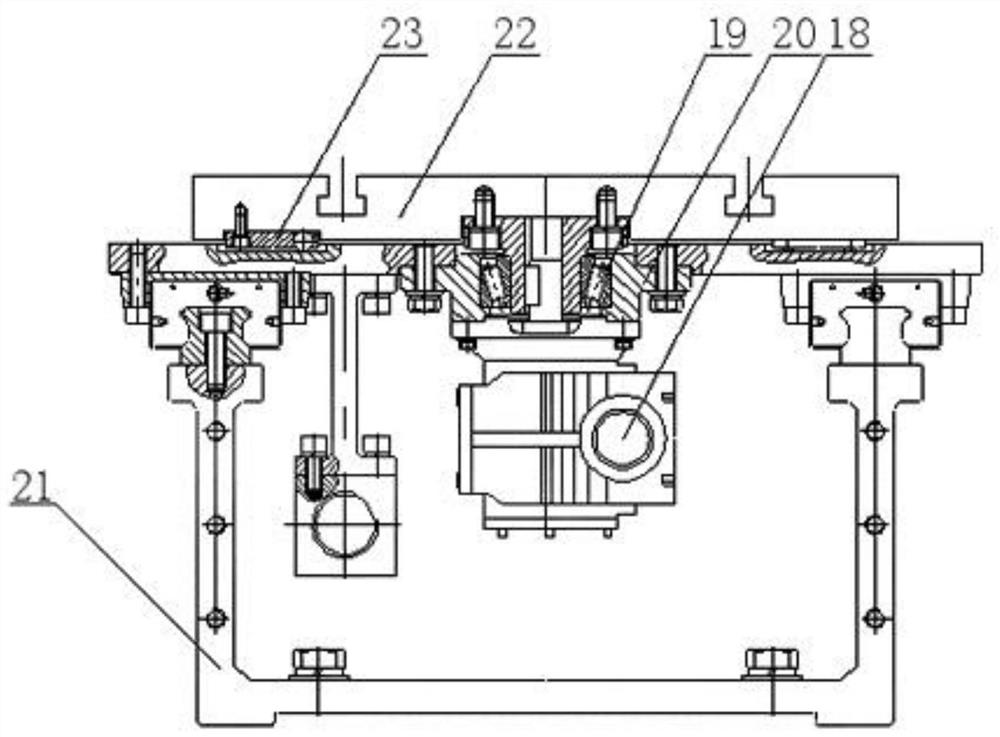

[0011] Figure 1 to Figure 3 A schematic diagram of the assembly structure of the present invention is shown. Such as Figure 1 to Figure 3As shown, the present invention provides a keyhole-free friction stir spot welding machine. It includes a frame, an X-axis mechanism, a Y-axis mechanism, a Z-axis mechanism, a rotary table 22 mechanism, a spindle system and a stirring head system. The frame includes a base 1, a column 2 and a top cover 3, and the column 2 is set on the base 1 , the number of columns 2 is four, the top cover 3 is set on the column 2, the X-axis mechanism and the Z-axis mechanism are set on the frame, the Y-axis mechanism is set on the X-axis mechanism, and the spindle system and the stirring head system are set on the Z-axis mechanism , the frame is equipped with a rotary table 22 mechanism, the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com