Polyurethane sponge insole and shoe midsole product

A technology of polyurethane sponge and polyurethane sponge layer, applied in insoles, footwear, clothing, etc., can solve problems such as heavy odor and insufficient shoe comfort, achieve good support, solve heavy odor, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

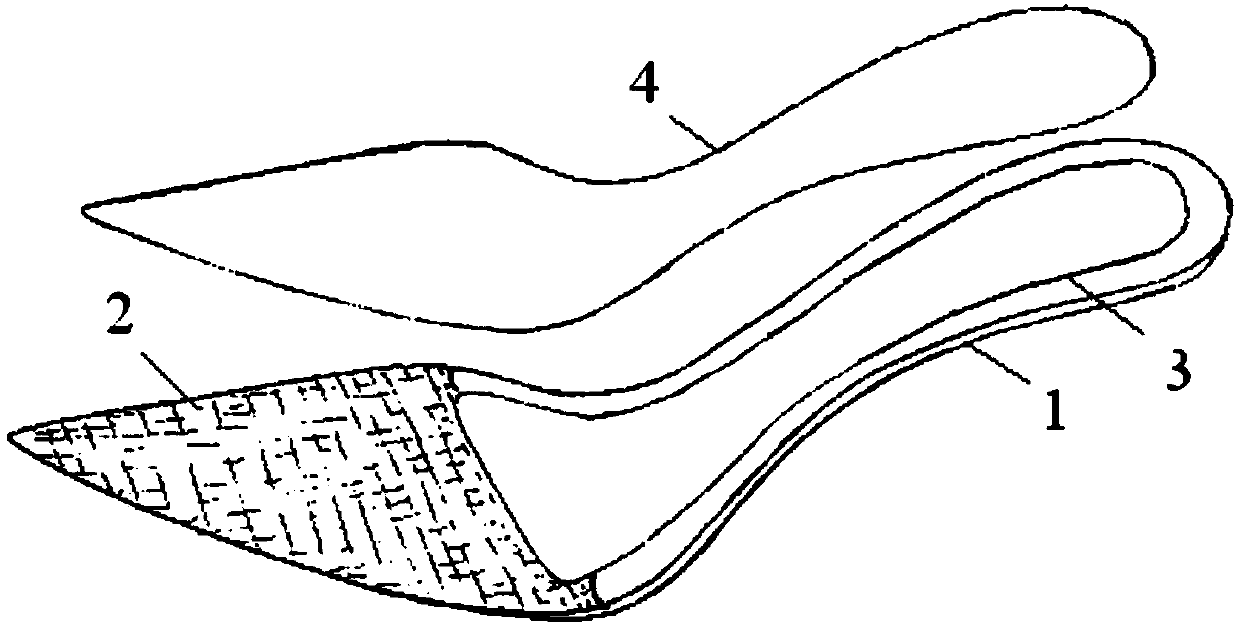

[0038] The polyurethane sponge insole provided in this embodiment comprises: a leather cushion layer and a polyurethane sponge layer.

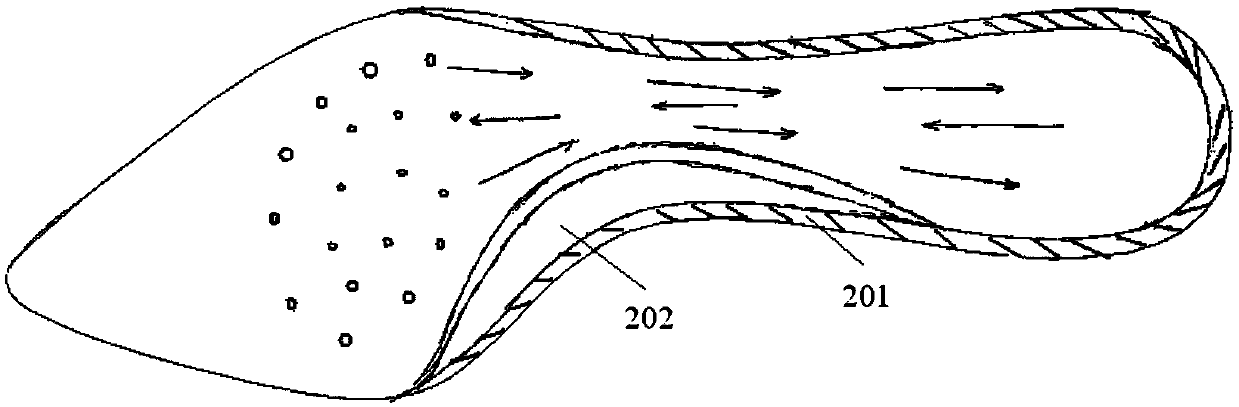

[0039] Wherein, the leather cushion is made of PU material with a thickness of 1 mm. The upper surface of the leather cushion is far away from the midsole; the shape of the front palm of the leather cushion is pointed. The forefoot portion of the leather cushion has a plurality of holes of the same size, the diameter of the holes is 0.5 cm, and the number is 40, evenly distributed. In addition, the lower surface of the leather cushion layer from the end of the forefoot to the rear peripheral edge of the heel is used to be firmly attached to the midsole. The width of the main body of the outer edge is basically the same, with a width of 3mm, and the width at both ends gradually decreases. is 0.

[0040] The inner side of the middle part of the leather pad is provided with an arc-shaped protrusion for fitting and supporting the arch of the foo...

Embodiment 2

[0047] The scheme of Example 1 is basically the same, the difference is that the density of the polyurethane sponge layer is 110g / cm 3 , hardness ≥ 90 degrees; stretch rate is 69.45%, tensile strength is 4.19kg / cm 2 , the tear strength is 22.65N / cm; the thickness is 3mm.

Embodiment 3

[0049] The scheme of Example 1 is basically the same, the difference is that the density of the polyurethane sponge layer is 90g / cm 3 , hardness ≥ 90 degrees; stretch rate is 63.27%, tensile strength is 3.62kg / cm 2 , The tear strength is 21.33N / cm; the thickness is 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com