Cycloid type reducer

A reducer and cycloid technology, applied in mechanical equipment, elastic couplings, transmission parts, etc., can solve the problems of idling phenomenon, reduced assembly efficiency, prolonged assembly time, etc., to increase rigidity and positioning accuracy, The effect of avoiding empty travel and reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention are described in detail below in conjunction with the accompanying drawings:

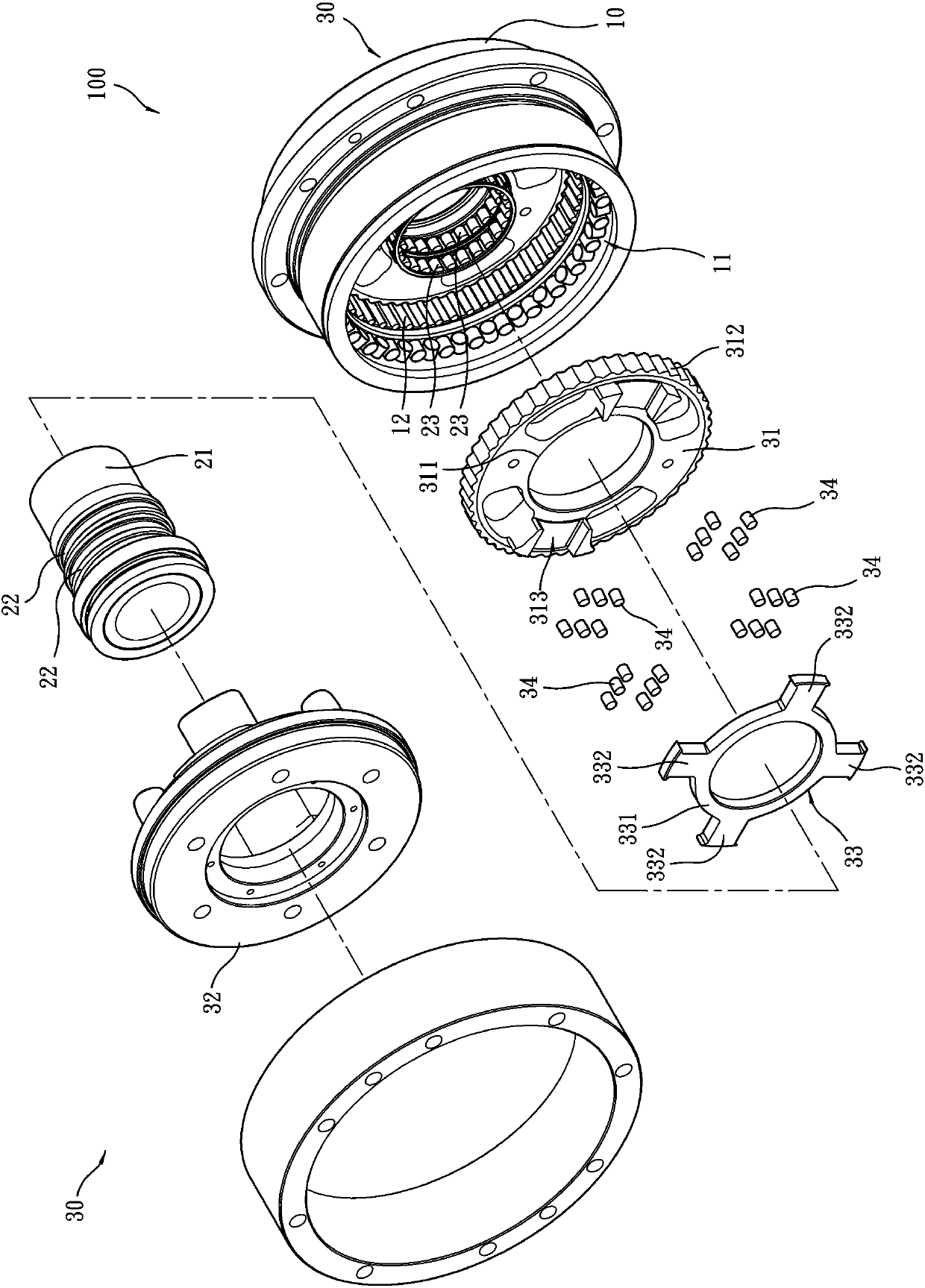

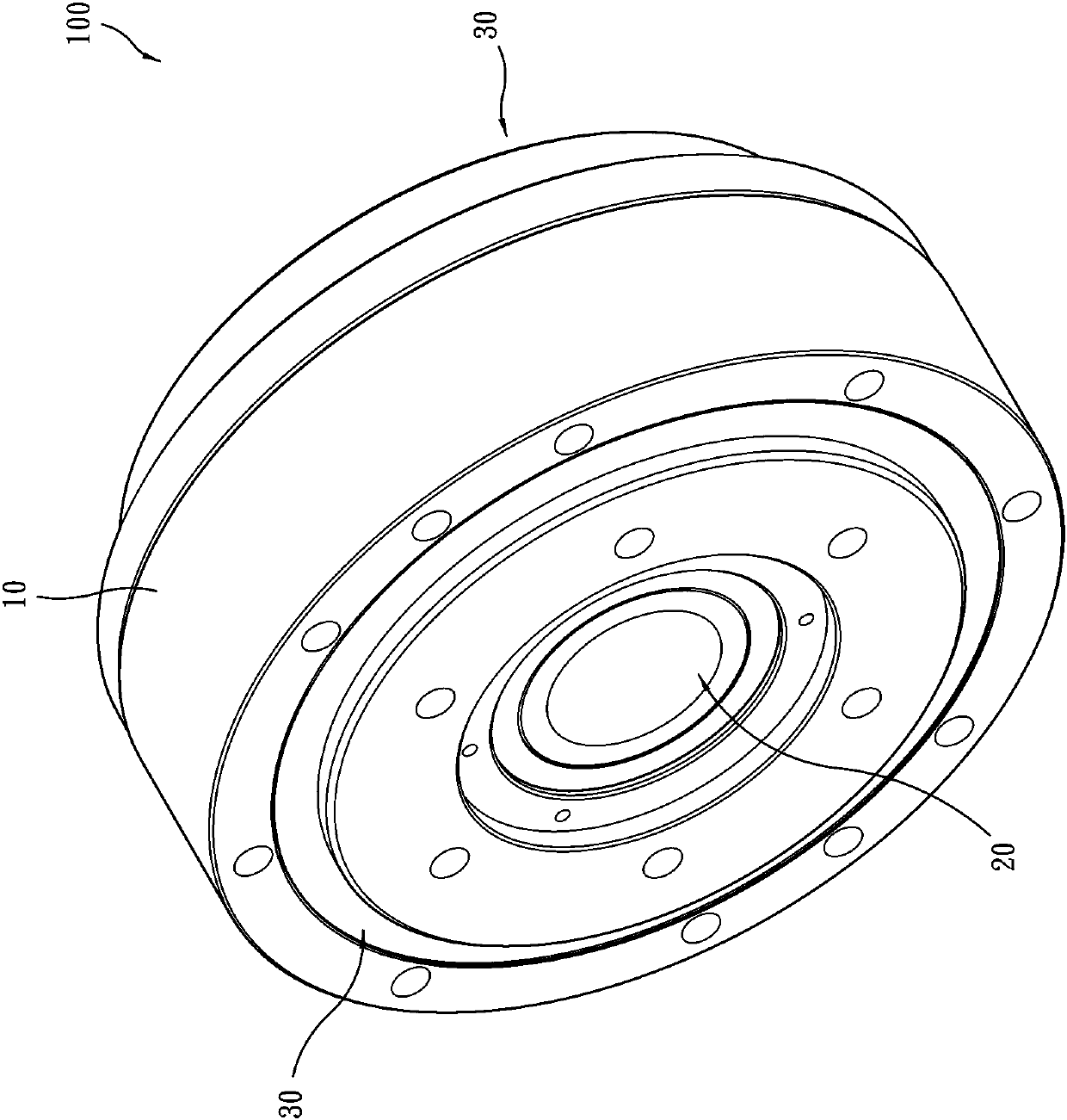

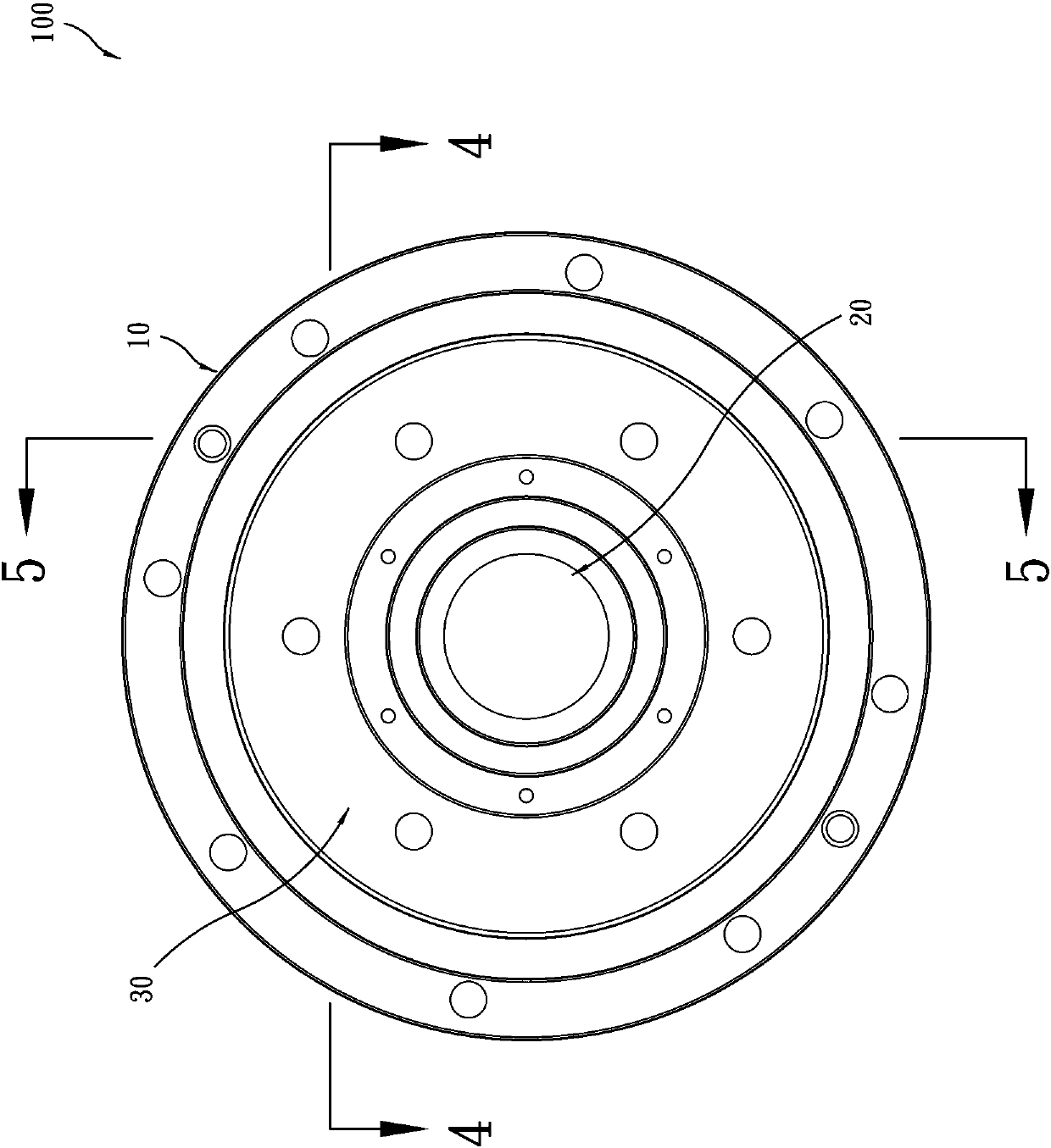

[0033] Such as Figure 1 to Figure 5 As shown, a cycloidal reducer 100 provided by a preferred embodiment of the present invention mainly includes a main body 10, an input shaft sleeve 20 and two deceleration output units 30, wherein:

[0034] The main body 10 has an axial assembly hole 11 and an annular inner tooth 12 formed on the inner peripheral surface of the axial assembly hole 11 .

[0035] The input shaft sleeve 20 has a shaft sleeve 21 , two eccentric sleeves 22 mounted on the shaft sleeve 21 and two bearings 23 respectively mounted on the eccentric sleeves 22 . The input sleeve 20 is placed in the axial assembly hole 11 of the main body 10 for inputting a deflection force.

[0036] The two deceleration output units 30 are arranged in the axial assembly hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com