Integrated electromechanical servo mechanism

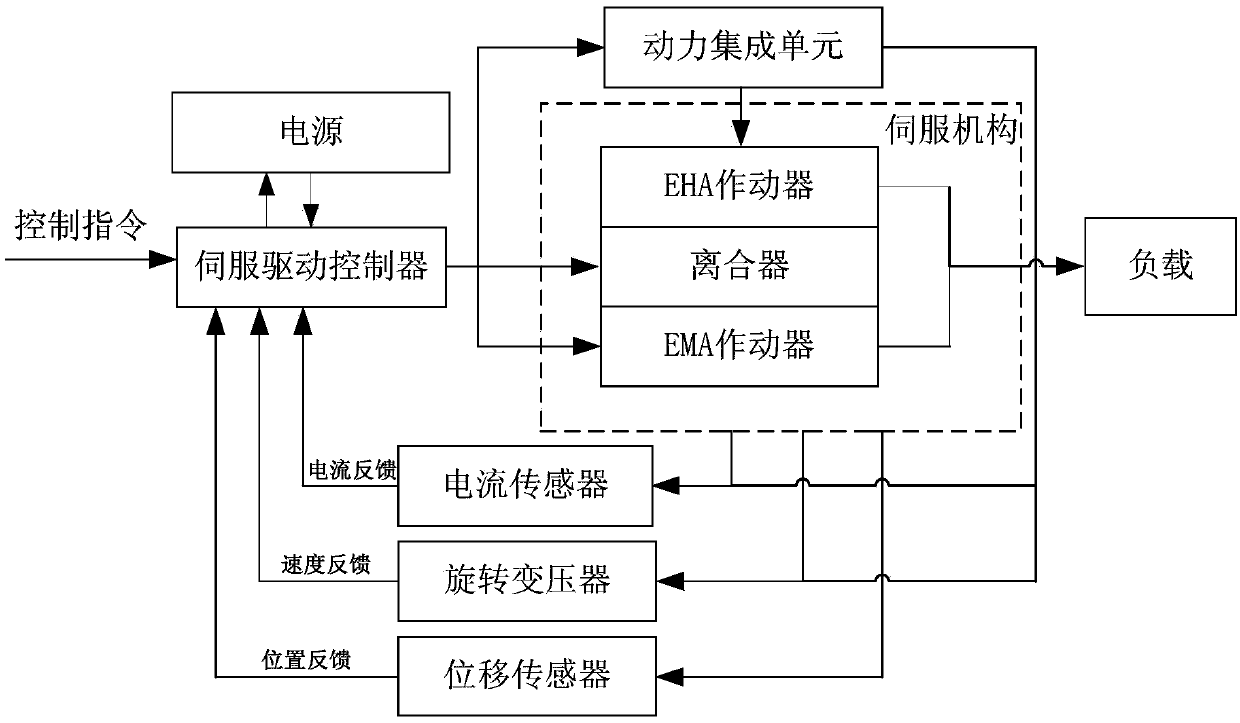

An electromechanical servo and integrated technology, applied in the direction of servo motor components, mechanical equipment, fluid pressure actuators, etc., can solve the problems of high operating efficiency and small footprint, achieve less cross-linking links, reduce vibration and noise , seamless and reliable switching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

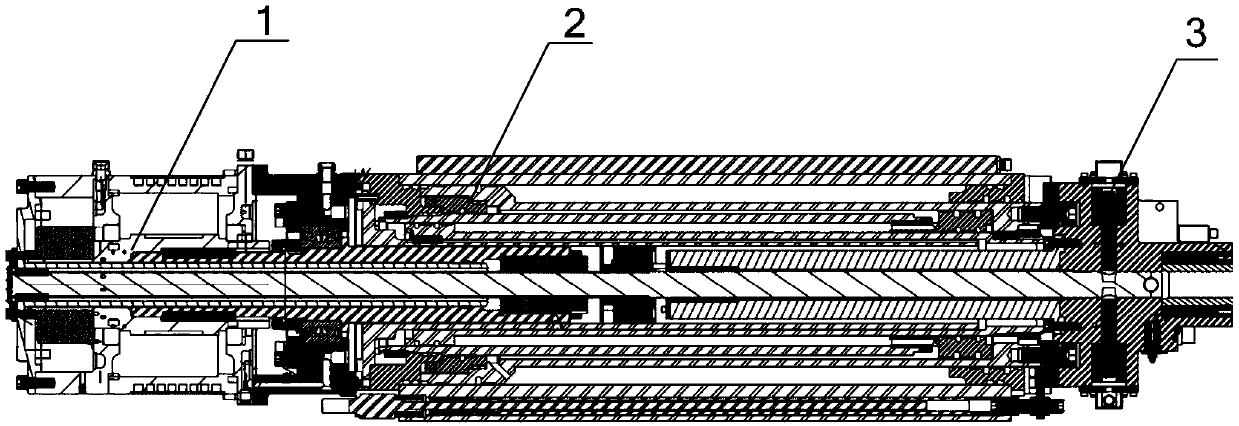

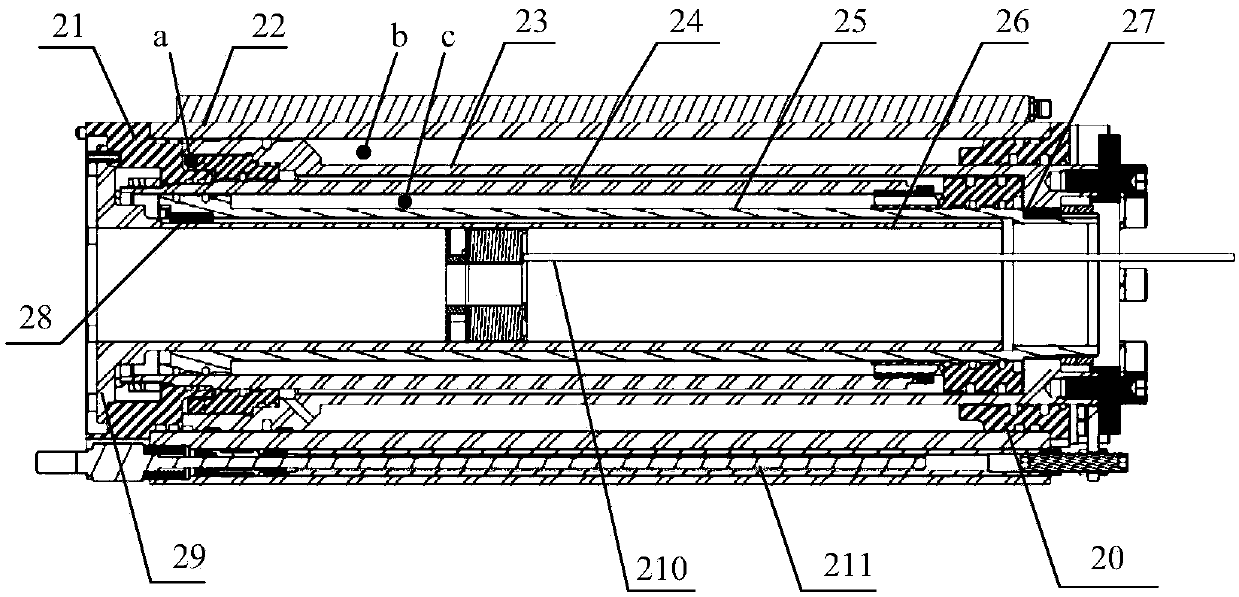

Embodiment

[0055] The power level of the EHA part of the implemented servo mechanism can reach 15kW, and the power level of the EMA part can reach 10kW, and the two can realize reversible seamless switching; its appearance is more compact and lighter, and it is about 20% smaller than the existing replaced products. , the weight is reduced by about 30%; in the military appraisal test of a certain type of ship in my country, according to the relevant requirements of the national military standard GJB4000-2000 and the development task book, the servo mechanism has been loaded and operated for 600 hours without interruption, and it works normally. The design requirements are met, and the reliability can be increased by 5% compared with the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com