Flexible mechanical arm

A manipulator and flexible technology, applied in the field of flexible manipulators, can solve problems such as inability to achieve flexible gripping, inability to grip objects of various sizes, single gripping method, etc., to achieve easy promotion and application, wide range of gripping objects, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the specific solution of the present invention will be further elaborated in conjunction with the accompanying drawings.

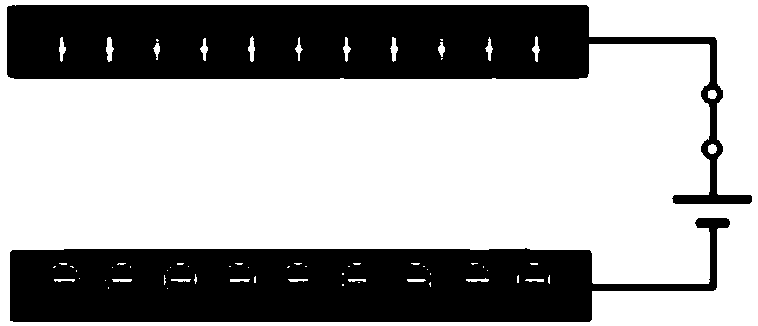

[0025] figure 1 As shown, the principle of electric field response of PVC gel film, the gel material creeps and condenses like an anode in the electric field.

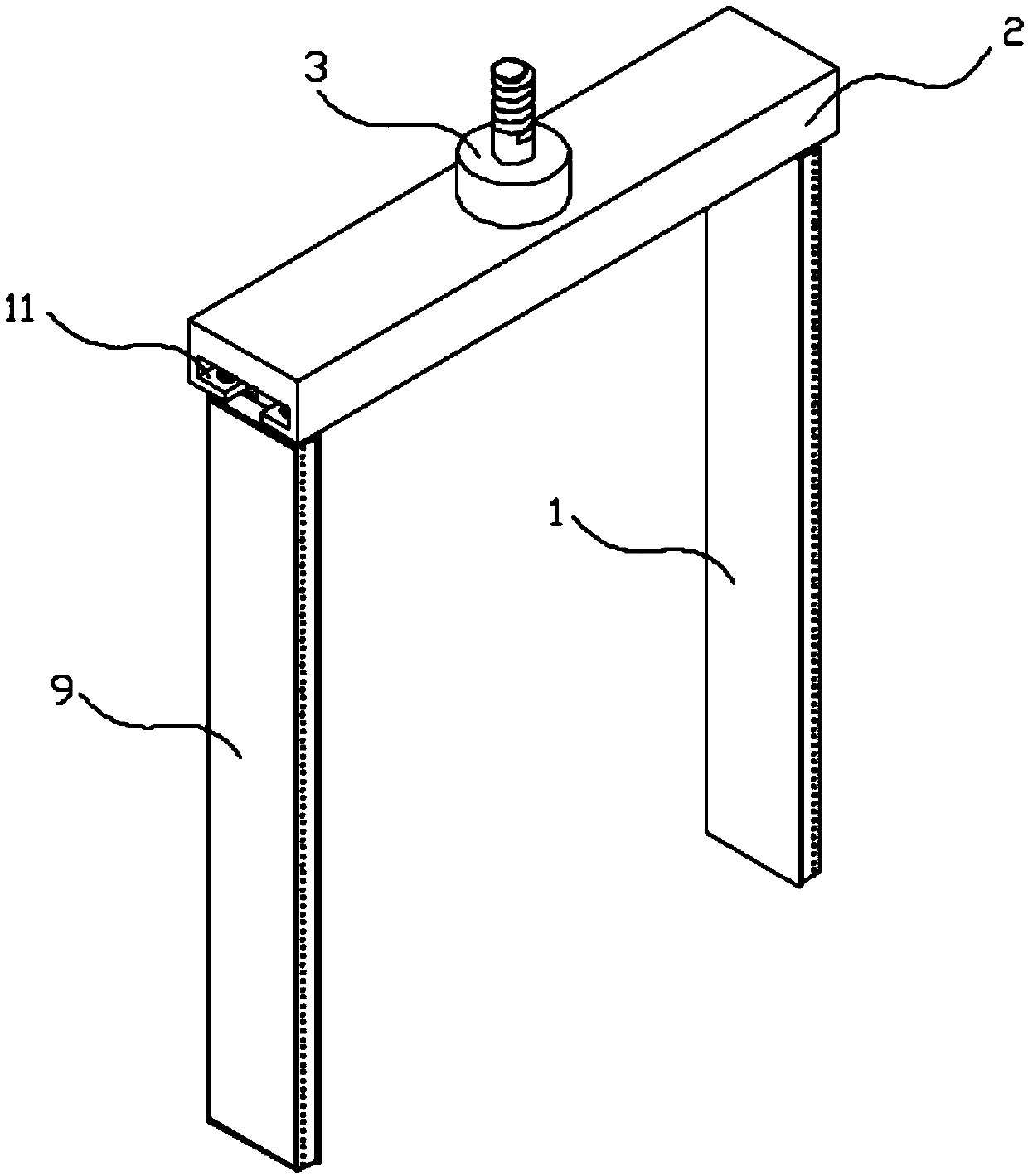

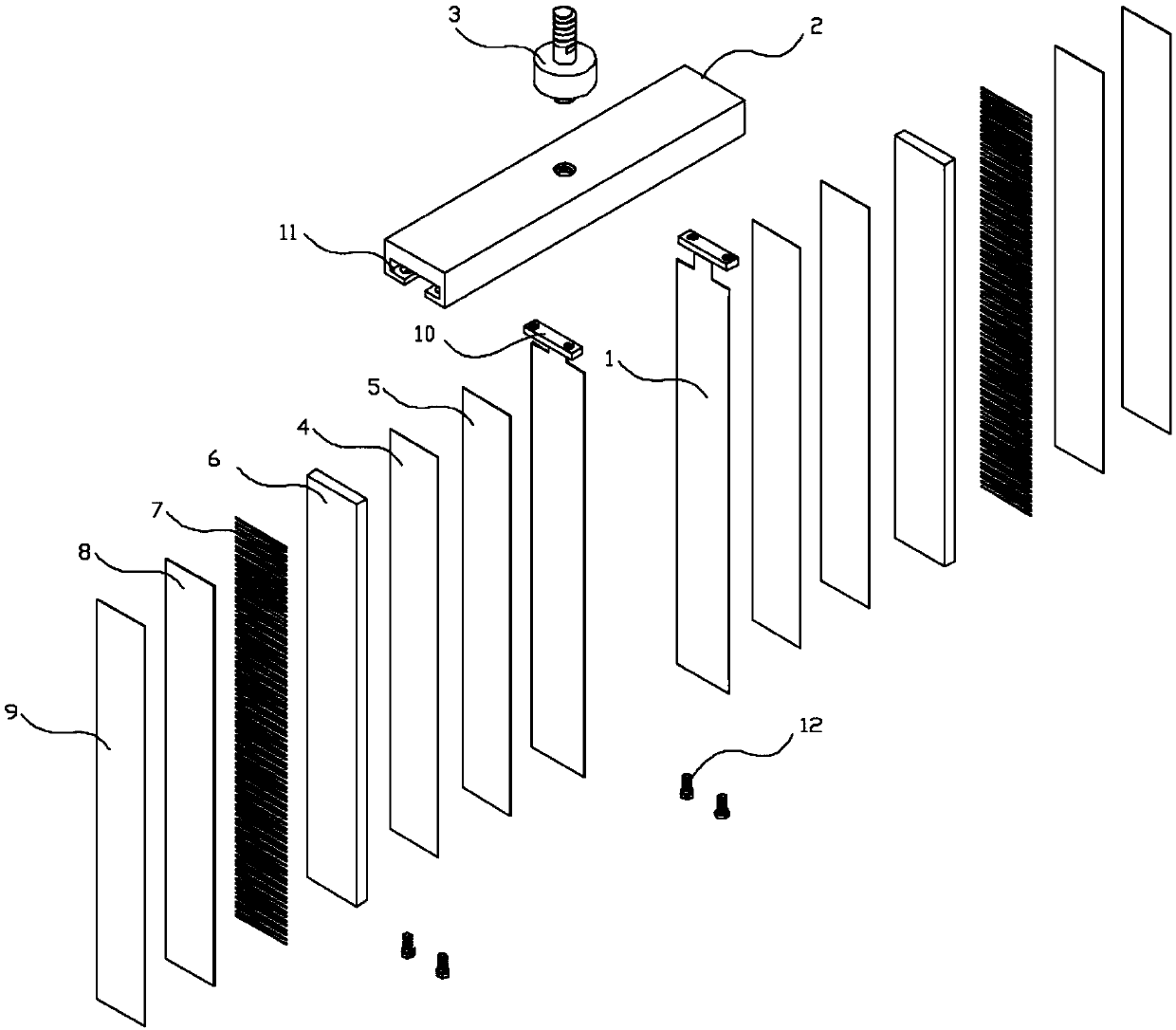

[0026] Such as Figure 2-4 As shown, the manipulator has an embodiment of a two-finger gel finger unit, such as Figure 5 Shown is an embodiment of a manipulator having a three-finger gel finger unit, each having the following structure.

[0027] A flexible manipulator, including a gel finger unit body 14 and a positioning adjustment guide rail 2, the gel finger unit body 14 includes a gel driver 6, a gripping part 1, and the gripping part 1 is fixed inside the gel driver 6 , the positioning adjustment guide rail 2 is slidably connected to the upper part of the gripping part 1, and the ends of several gel finger unit bodies 14 are flexibly opened and closed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com