A pretreatment device for pickling steel coils

A pre-treatment, steel coil technology, applied in the field of steel pickling equipment, can solve the problems of shortening the service life of the emulsion, affecting the surface quality and processing performance of the cold-rolled sheet, and being expensive, so as to improve the effective utilization rate and enhance the preliminary The effect of the burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

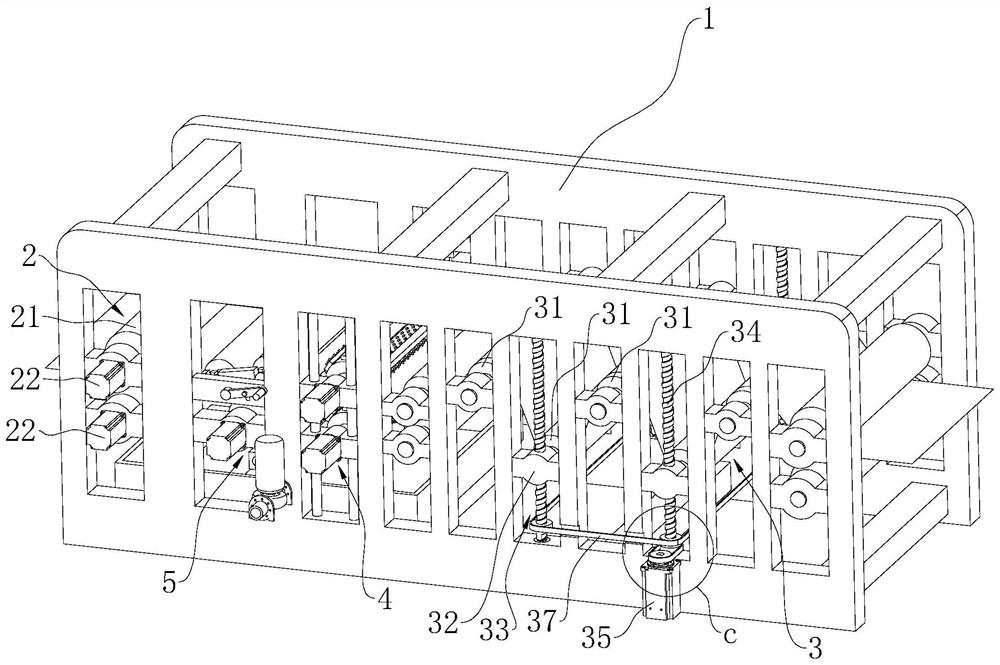

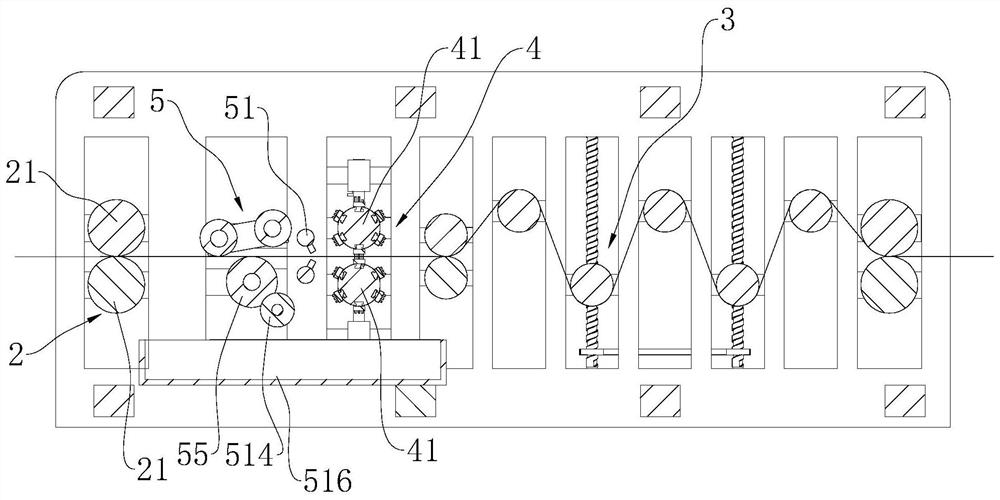

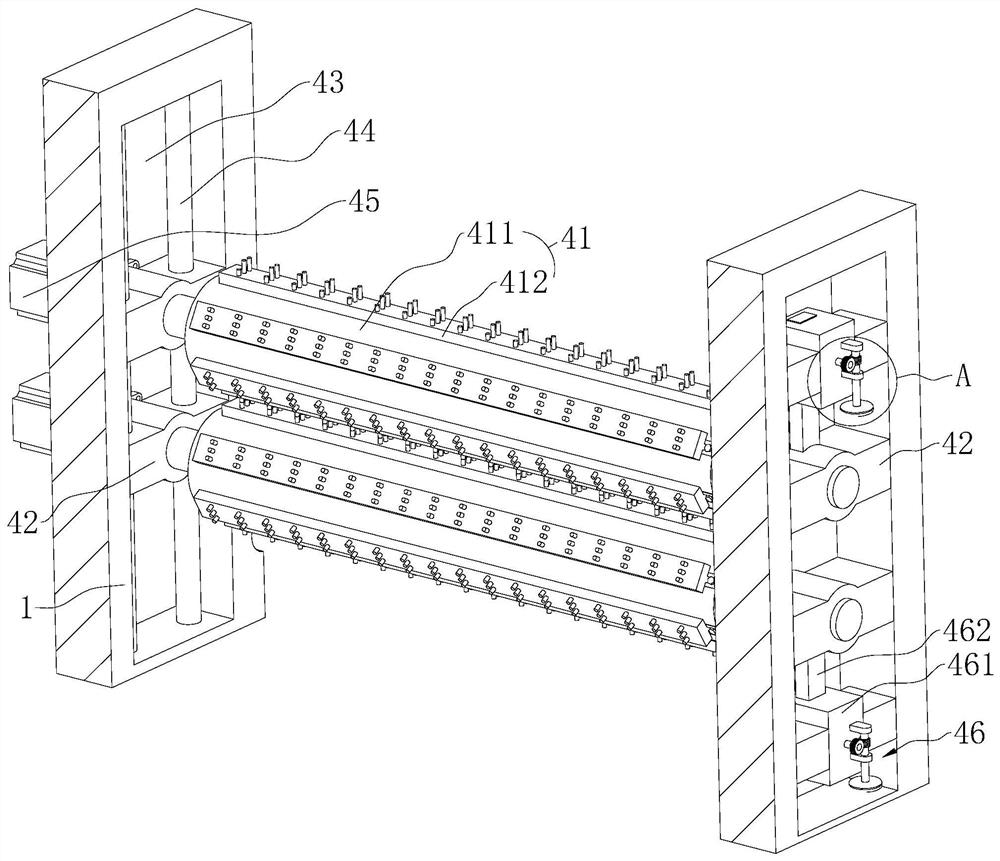

[0051] refer to figure 1 and 2 , which is a pre-processing device for pickling steel coils disclosed in the present invention, comprising a frame 1, a bending mechanism 3 arranged in sequence along the length direction of the frame 1, a scale breaking mechanism 4, a cleaning mechanism 5, and a driving mechanism 2; Under the driving action of the driving mechanism 2, the steel coil passes through the bending mechanism 3 for bending, the scale breaking mechanism 4 breaks the surface layer, and the cleaning mechanism 5 cleans the surface, so that the oxide scale on the surface of the steel coil is broken, which is convenient for subsequent The steel coil enters the pickling device for pickling.

[0052] The working principle of the driving mechanism 2 is as follows:

[0053] It includes two conveying rollers 21, and the two ends of the two conveying rollers 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com