Intelligent clamping clamp for 8-shaped double-hole aluminum sleeve

A figure-8, clamping pliers technology, used in hand-held tools, manufacturing tools, etc., can solve problems such as personal and property damage, potential safety hazards, unreliable connections, etc., to achieve strong versatility, reduce possibility, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0045] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

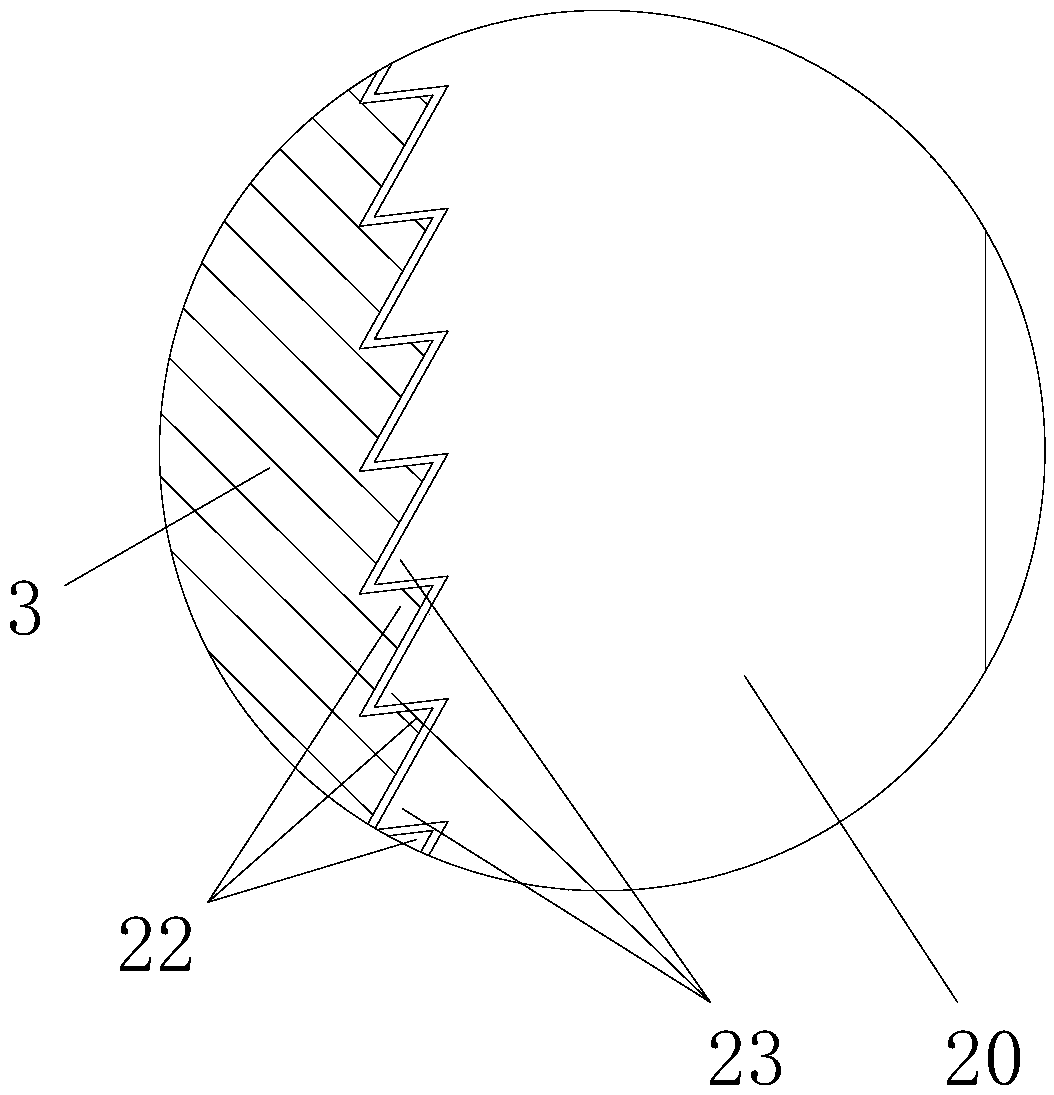

[0046] Such as figure 1 As shown, in this embodiment, the A direction represents the front, and the B direction represents the rear. This embodiment provides an intelligent clamping pliers for an 8-shaped double-hole aluminum sleeve, including a housing 1 , an extruding mechanism, a locking mechanism, a clamping mechanism, a positioning mechanism and a control module 2 . Wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com