Micro centrifuge

A centrifuge and micro technology, applied in the field of laboratory equipment, can solve the problems of reading errors and inconvenience in reading centrifuge test tubes, and achieve the effects of preventing errors, uniform force and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

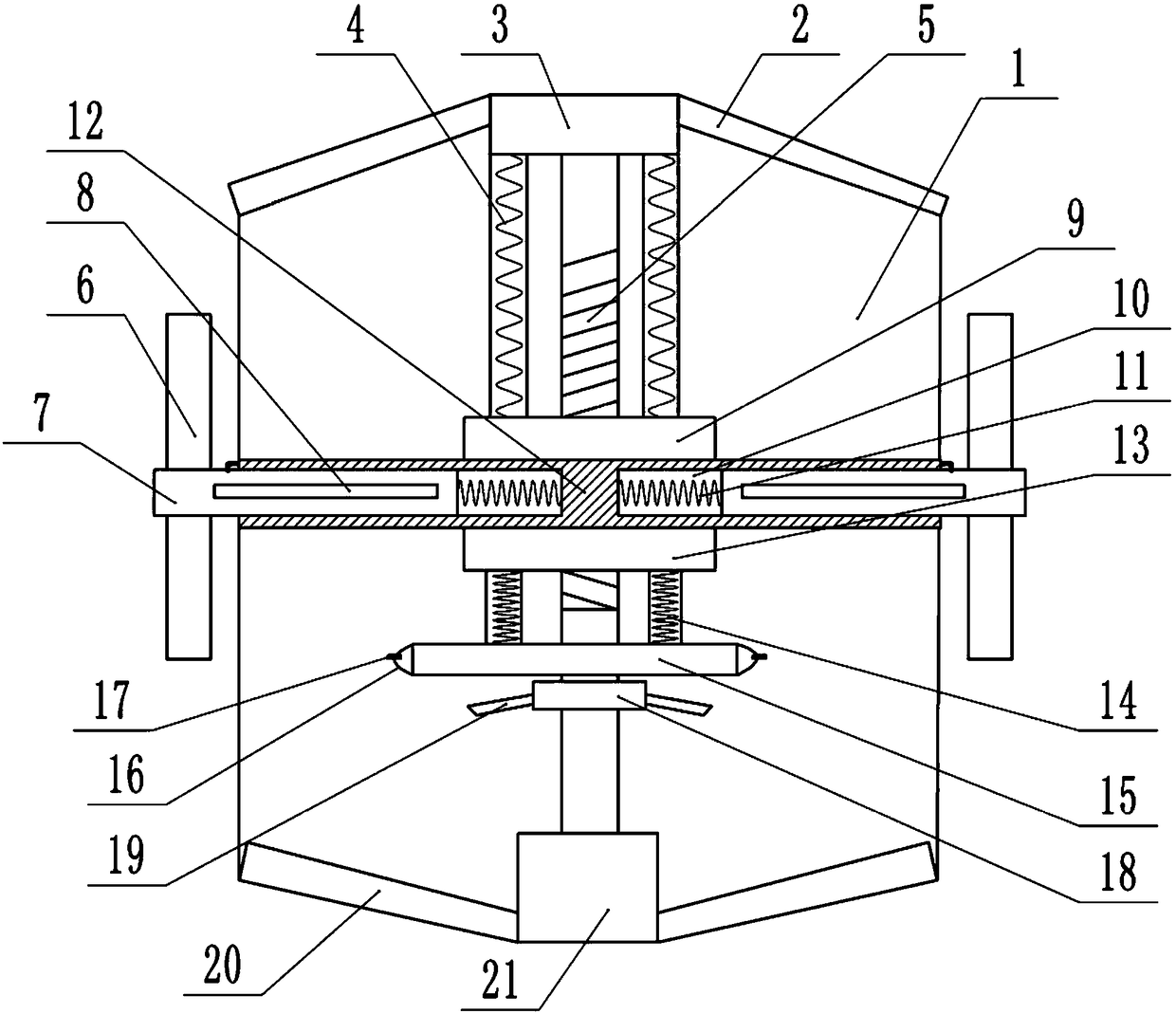

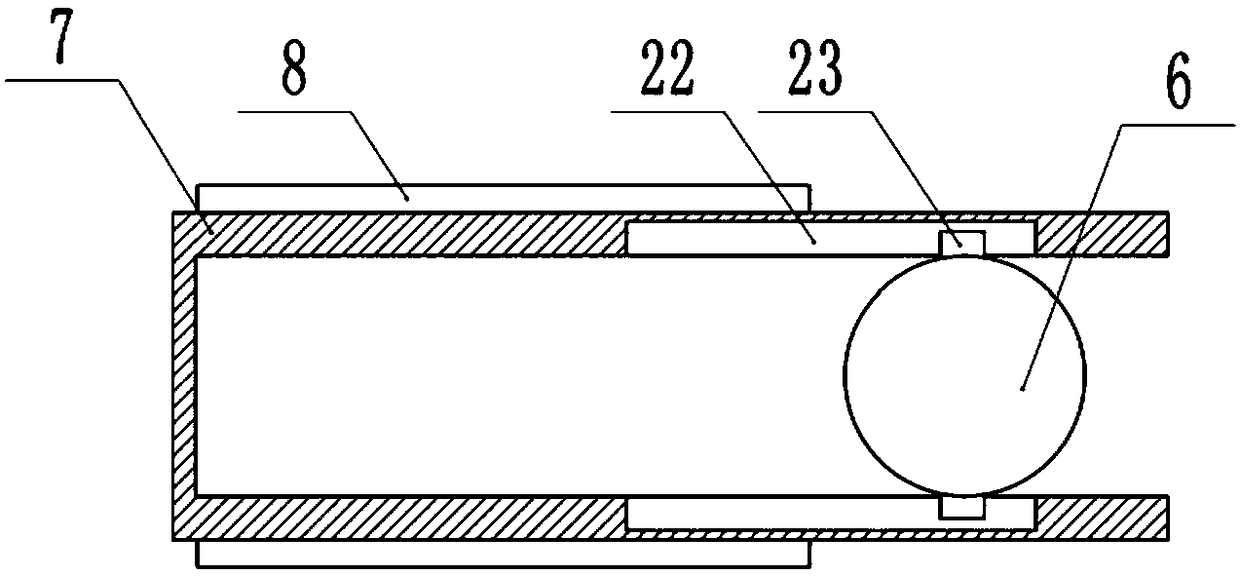

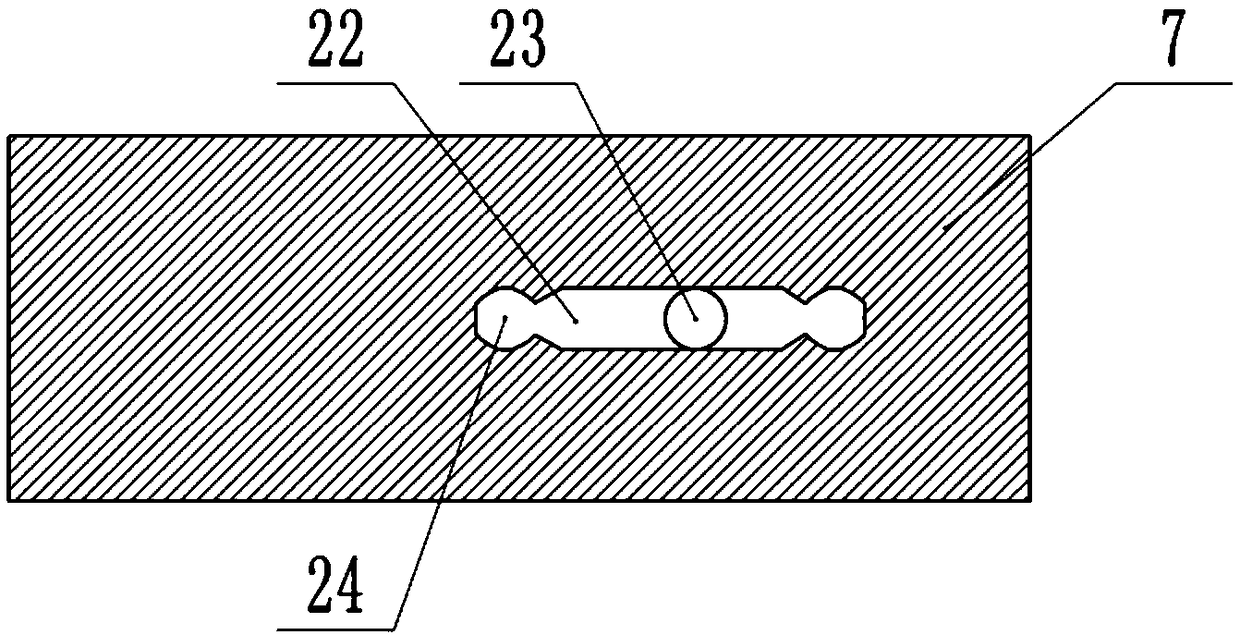

[0025] The reference signs in the drawings of the specification include: housing 1, upper cover 2, fixed block 3, upper compression spring 4, rotating shaft 5, test tube 6, carriage 7, sliding bar 8, first magnet 9, sliding cavity 10, Extension spring 11, turntable 12, second magnet 13, lower pressure spring 14, blast shell 15, elastic layer 16, pressure valve 17, blower fan 18, fan blade 19, lower cover 20, motor 21, chute 22, round Block 23, rotating groove 24.

[0026] The embodiment is basically as attached Figure 1-Figure 4 As shown: a microcentrifuge, including a housing 1, an upper cover 2 and a lower cover 20 are integrally formed on the housing 1, a fixed block 3 is integrally formed on the upper cover 2, a battery and a motor 21 are installed on the lower cover 20, and the battery Used to supply power to the motor 21 , the outer side of the casing 1 is provided with a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com