Circuit board feeding device

A circuit board and conveying device technology, which is applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of large space occupation, increased maintenance costs, and high costs, and achieves improved feeding accuracy, small space occupation, and high cost. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

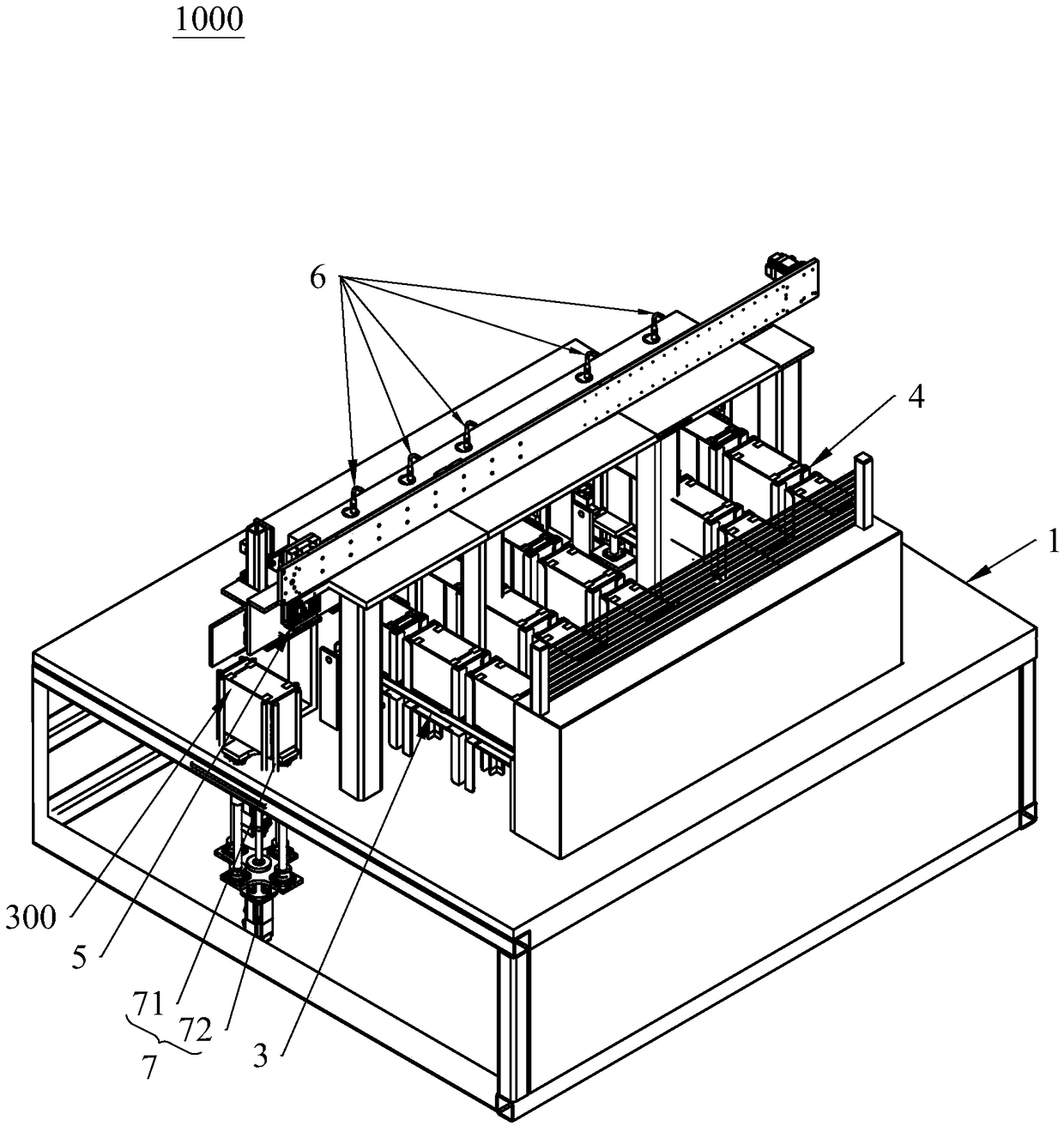

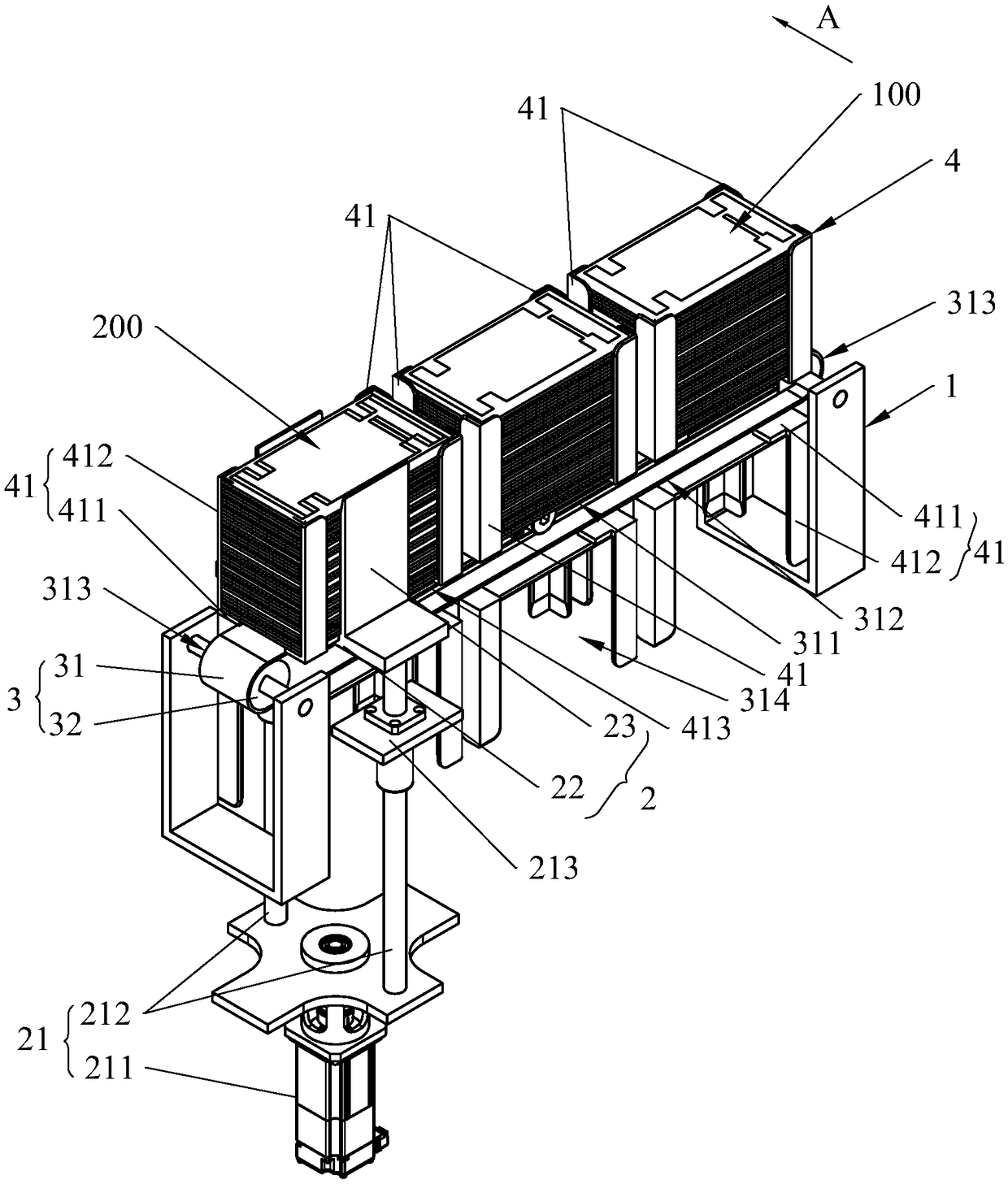

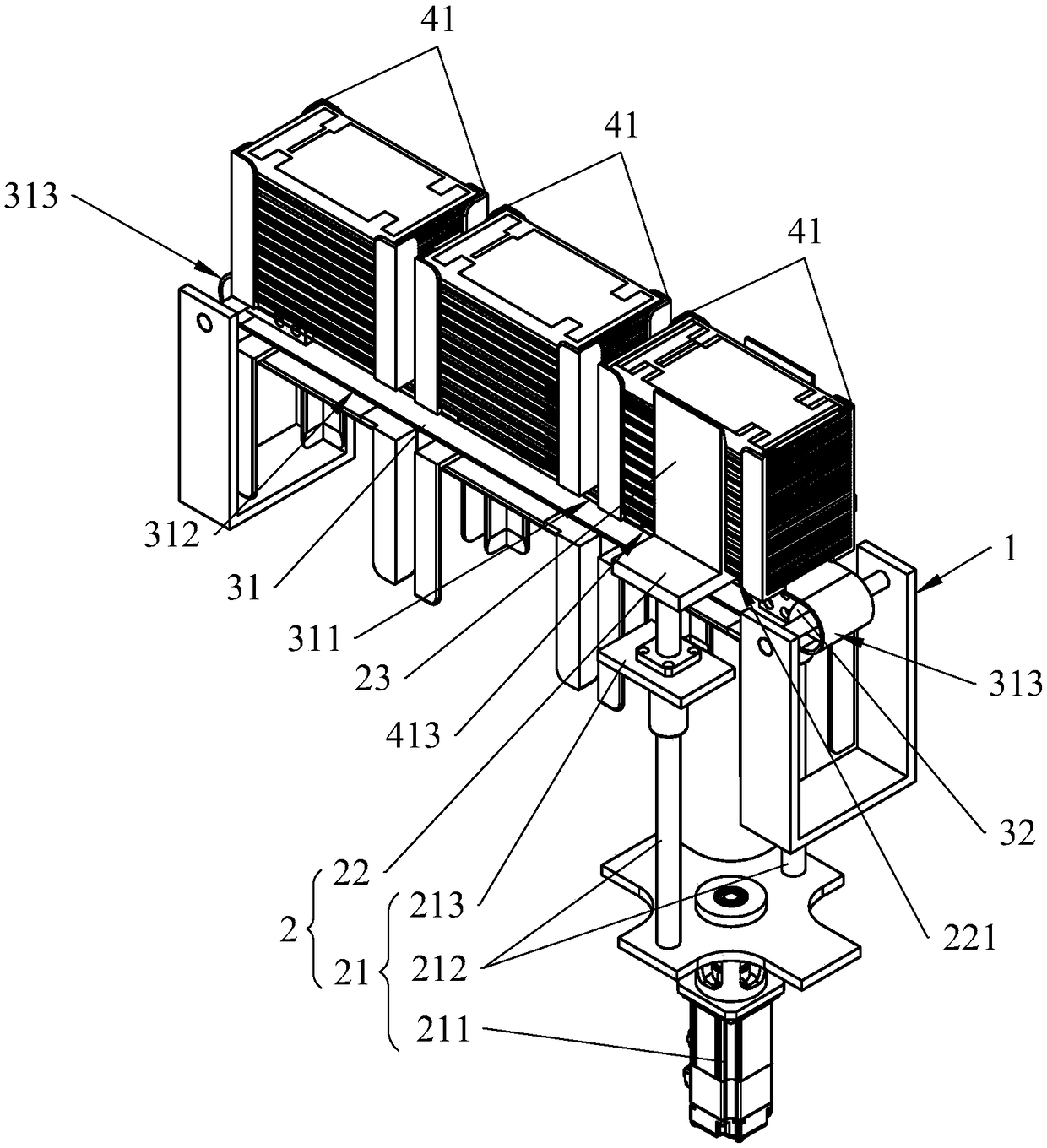

[0023] see Figure 1 to Figure 2 , the circuit board feeding device 1000 of the present invention is suitable for being electrically connected with an external controller (not shown in the figure), and the circuit board feeding device 1000 includes a frame 1 and a transfer manipulator 5, a top The lifting mechanism 2, the conveying device 3 and the limit frame 4 used to limit the stacked circuit boards, the conveying device 3 has a transmission part 31 that can perform rotary motion, and the limit frame 4 is fixed on the transmission part 31, Preferably, there are at least two limit frames 4, and all limit frames 4 are spaced and fixed on the transmission member 31, and the interval between two adjacent limit frames 4 is equal; the two ends of the transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com