Catalyst composition comprising magnetic material adapted for inductive heating

A magnetic material and induction heating technology, applied in catalyst carrier, molecular sieve catalyst, catalyst activation/preparation, etc., can solve problems such as incompatibility, high energy consumption, and low heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

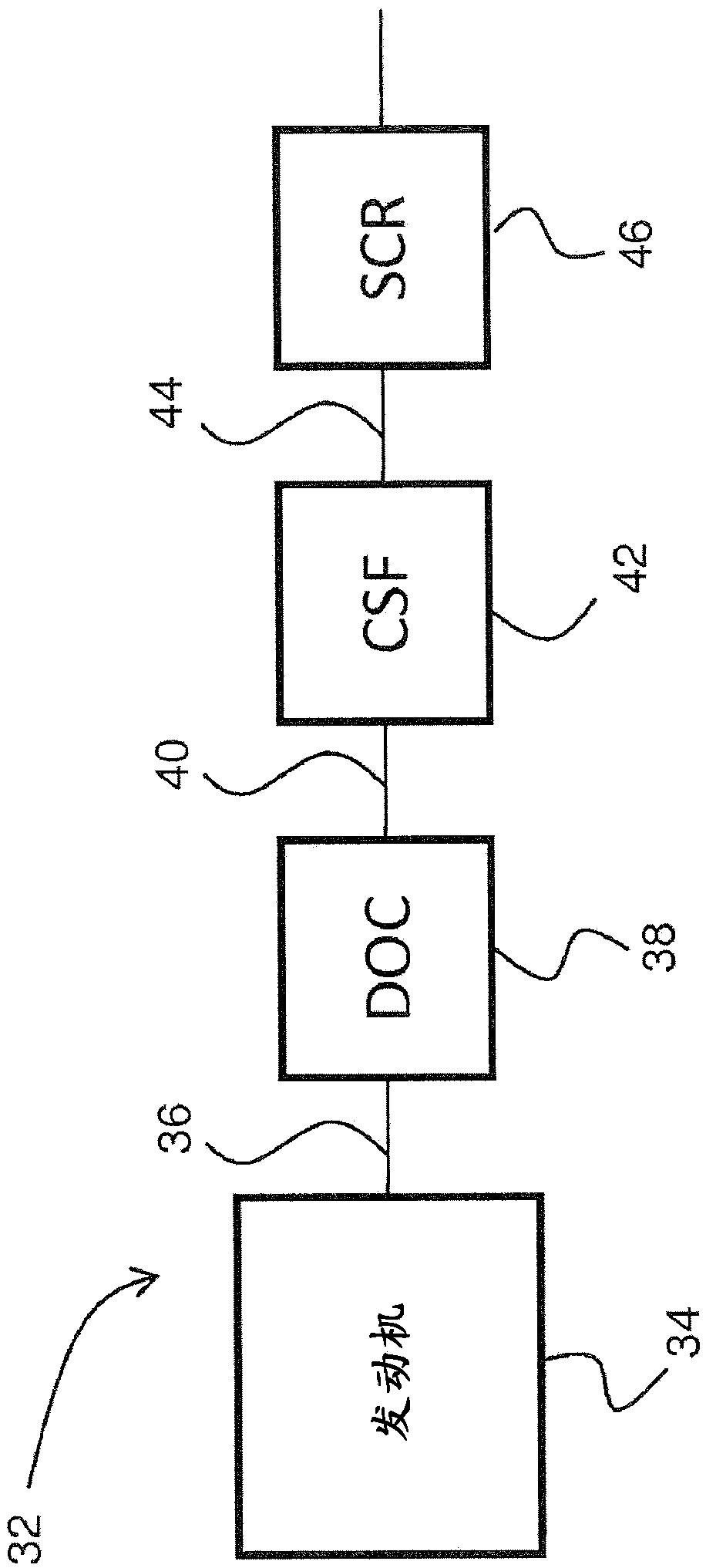

[0048] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0049] Hereinafter, the present invention will be described in more detail. Although the invention is described herein with reference to specific embodiments, it should be understood that these embodiments are merely illustrative of the principles and applications of the invention. Those skilled in the art can make various improvements and changes to the method and equipment of the present invention without departing from the spirit and scope of the present invention. Thus, it is intended that the present invention includes the modifications and changes that come within the scope of the appended claims and their equivalents. It should be understood that the invention is not limited to the details of construction or process steps described hereinafter. The invention is capable of other embodiments and of being practiced or carried out in various ways. Like numbers indicate like elements. As used in the specification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com