System for monitoring storage capacity of cement bin

A monitoring system, cement silo technology, applied in signal transmission systems, control/regulation systems, measuring devices, etc., can solve problems such as difficulty in level measurement and display, achieve high safety and convenience, and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

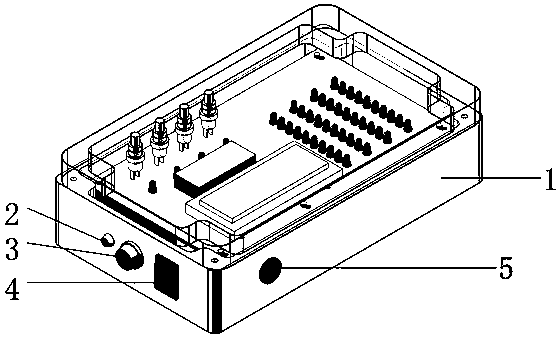

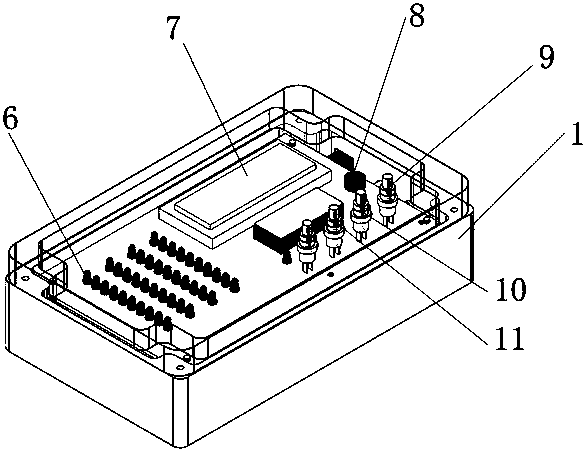

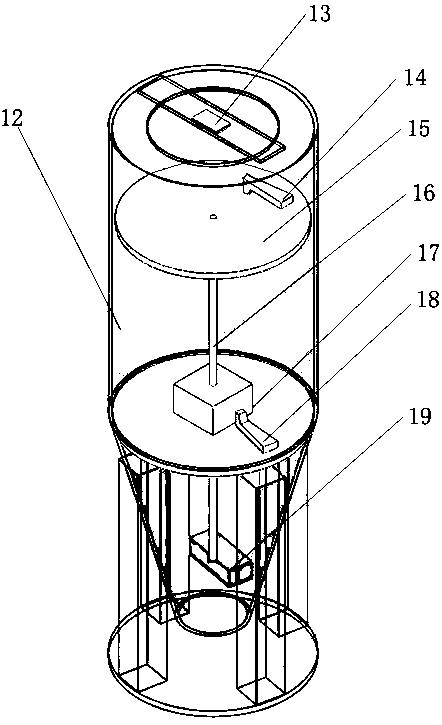

[0043] Such as Figures 1 to 19 As shown, the cement silo storage monitoring system of this embodiment includes a cement silo material monitoring device arranged on the cement silo and a cement silo material control device for controlling material delivery and displaying the cement silo storage. The cement silo material The control device is connected to the cement silo material monitoring system through a wireless communication module, and the cement silo material control device includes a control box 1 with a cement silo material control component on the inner top, a cement silo material control circuit and a wireless communication module on the inner bottom, The cement silo material control component, the cement silo material control circuit and the wireless communication module are electrically connected, and the cement silo material monitoring device includes a cement silo material monitoring component arranged on the cement silo body 12, and a cement silo material monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com