A slider bonding process equipment and bonding method

A process equipment and bonding technology, applied in mechanical equipment, connecting components, etc., can solve the problems of uneven thickness, low adaptability and versatility, and high production cost, achieve good adaptability and versatility, and avoid copper grooves. The effect of uneven thickness and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

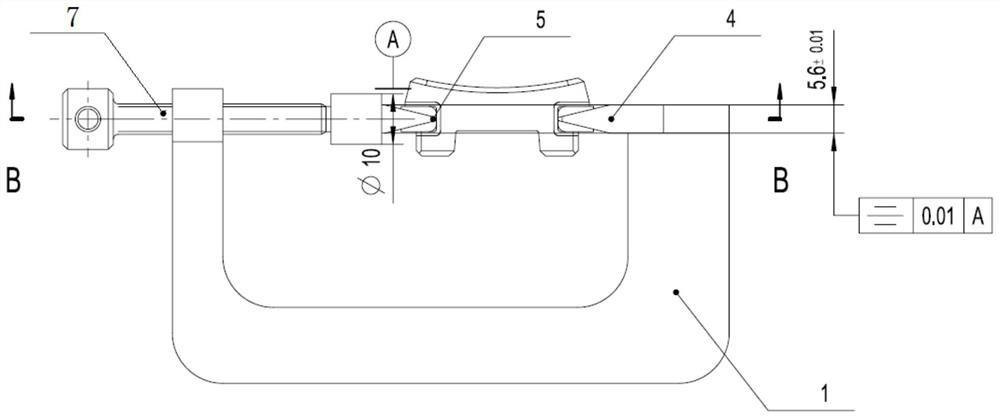

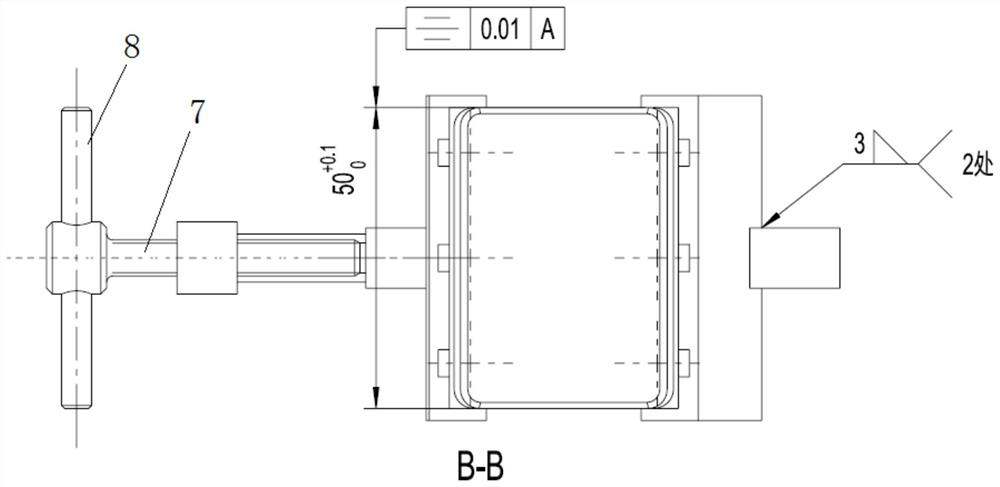

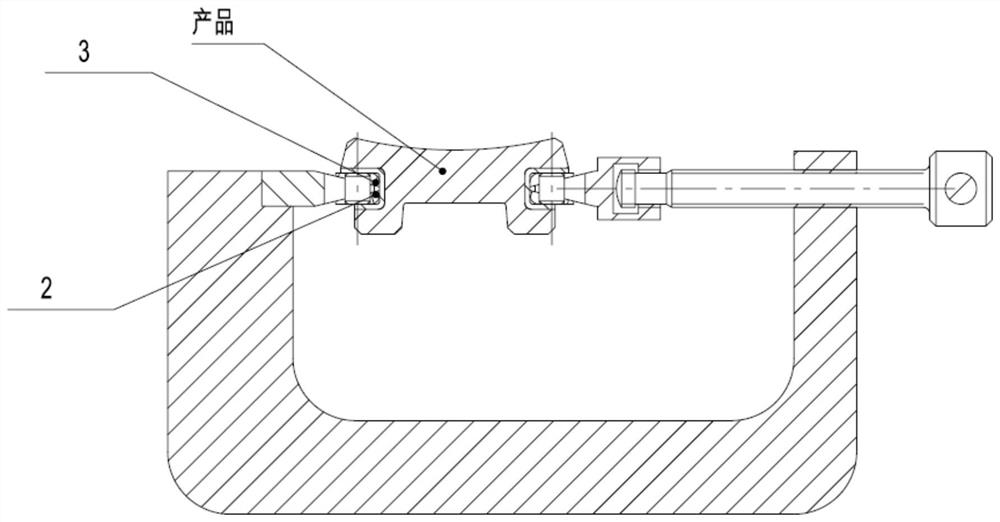

[0041] Such as Figure 1-9 As shown, the slider bonding process equipment described in this embodiment may specifically include: a bow clamp 1, a first jacking block 2, a second jacking block 3, a third jacking block 4, a fourth jacking block 5, and a positioning pin 6 , movable handle compression screw 7 and movable handle 8.

[0042] In this embodiment, one end of the bow clip 1 is provided with a threaded hole, and the movable handle pressing screw 7 is installed on the bow clip 1 through the threaded hole; the other end of the bow clip 1 is provided with a groove, and the second top block 3 Installed in the groove of the bow clip 1, and welded to shape. The movable handle compression screw 7 is provided with threads and mounting holes, and the fourth top block 5 is threadedly connected with the movable handle compression screw 7; the movable handle 8 passes through the mounting hole and is connected with the movable handle compression screw 7. The first jacking block 2 a...

Embodiment 2

[0052] The invention also discloses a bonding method, which includes: connecting the fourth top block 5 with one end of the bow clamp 1 by pressing the screw 7 through the movable handle; wherein, one end of the bow clamp 1 is provided with a threaded hole, and the movable handle presses Screw 7 is provided with screw thread and installation hole, movable handle pressing screw 7 is installed on the bow clamp 1 through the threaded hole on the bow clamp 1, the fourth jacking block 5 compresses the screw thread on the screw 7 and the movable handle through the movable handle The compression screw 7 is connected; the movable handle 8 is connected with the movable handle compression screw 7 through the mounting hole on the movable handle compression screw 7; the second top block 3 is installed in the groove at the other end of the bow clip 1, and Forming with welding; through the positioning pin 6, the first jacking block 2 and the second jacking block 3 are positioned and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com