Radial ejector

A technology of injectors and injection chambers, which is applied in the direction of injection pumps, machines/engines, non-volume pumps, etc., can solve the problems of axial installation size error of nozzle pipes, large noise of water flow in injection pipes, inconvenient use, etc., and achieve improvement Performance, reduction of water flow noise, and lightness of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

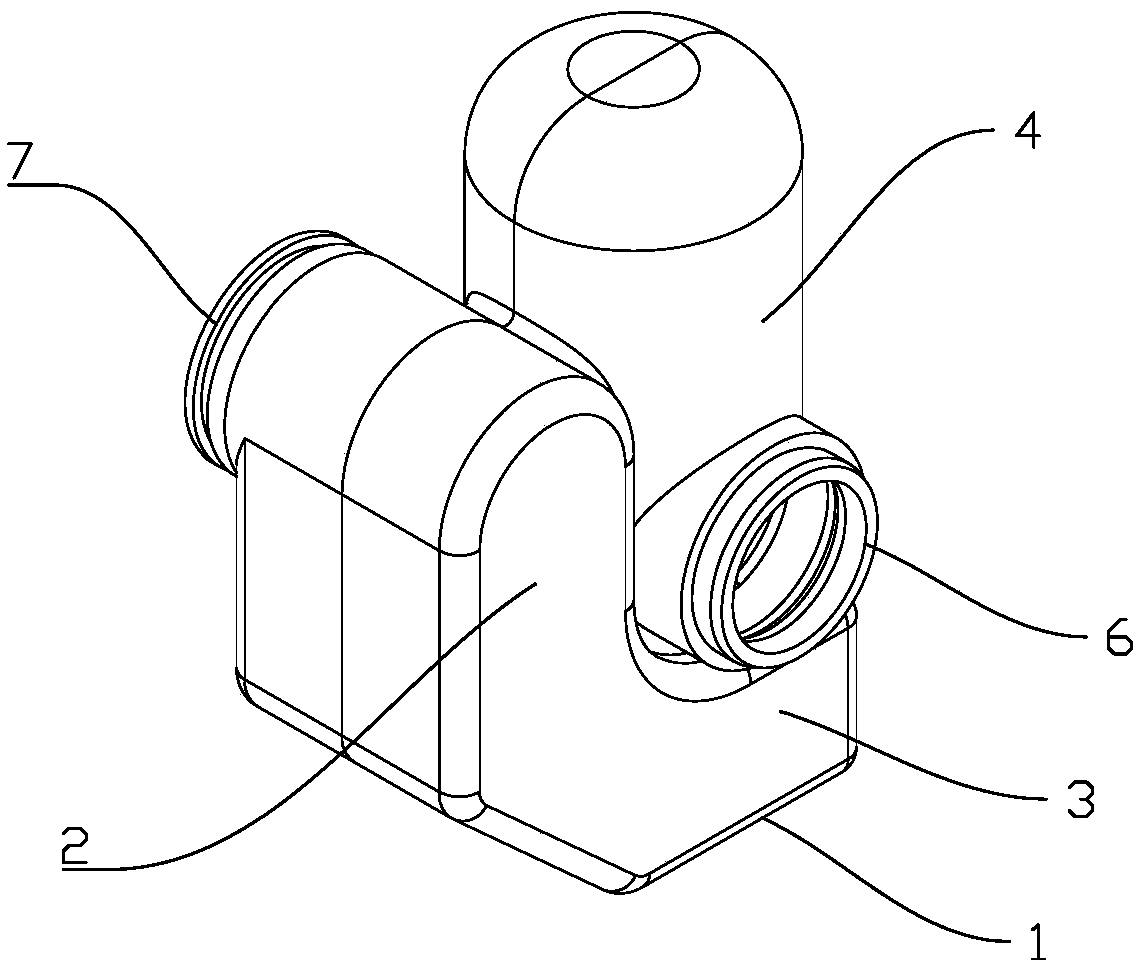

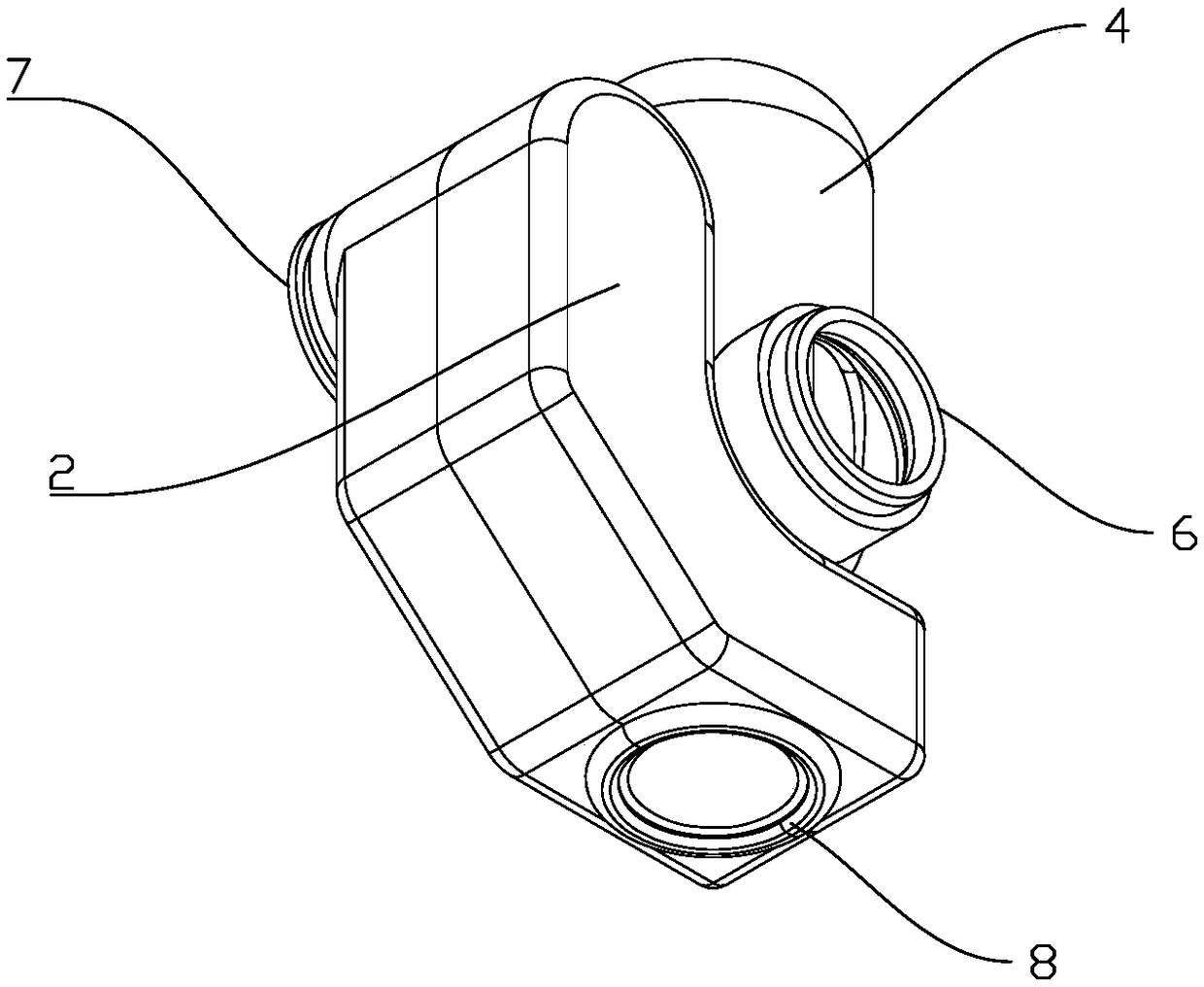

[0022] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-5 :

[0023] The radial injector includes an injector housing 1, and the injector housing 1 is provided with a suction chamber 2, a mixing chamber 3 and an injection chamber 4, the suction chamber 2 and the injection chamber 4 are arranged side by side, and the mixing chamber 3 is arranged in the injection chamber. The bottom of the chamber 4 communicates with the suction chamber 2, the injection chamber 4 is provided with an injection pipe 5, one side of the injection chamber 4 is radially provided with an injection port 6, and the side of the suction chamber 2 opposite to the injection port 6 A suction port 7 is arranged radially, and the suction port 7 is connected to the injection medium fluid. The bottom of the mixing chamber 2 is provided with a nozzle 8, and the nozzle 8 is connected to the working medium fluid.

[0024] The wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com