Square tube scaffold connector and square tube scaffold

A scaffolding and joint technology, applied in the field of scaffolding, can solve the problems of easy slippage of round pipes, reduced construction efficiency, time-consuming and labor-intensive, etc., and achieves the effects of fast and efficient lap jointing, simple structure, and safe and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] see figure 1 , this embodiment provides the first square tube scaffolding 100 . The first type of square tube scaffold 100 includes a first type of square tube scaffold joint 01 , a column 02 and a first type of square tube 03 . The first type of square tube scaffold joint 01 is arranged on the column 02 , and the first type of square tube scaffold joints 01 are connected together by the first type of square tube 03 . A plurality of first-type square tube scaffold joints 01 , upright columns 02 and first-type square tubes 03 with different quantities are combined and connected to form a square tube scaffold, and finally form the entire scaffolding project.

[0046]The specific structure of each sub-component of the square tube scaffold 100 of the first type will be introduced in detail below.

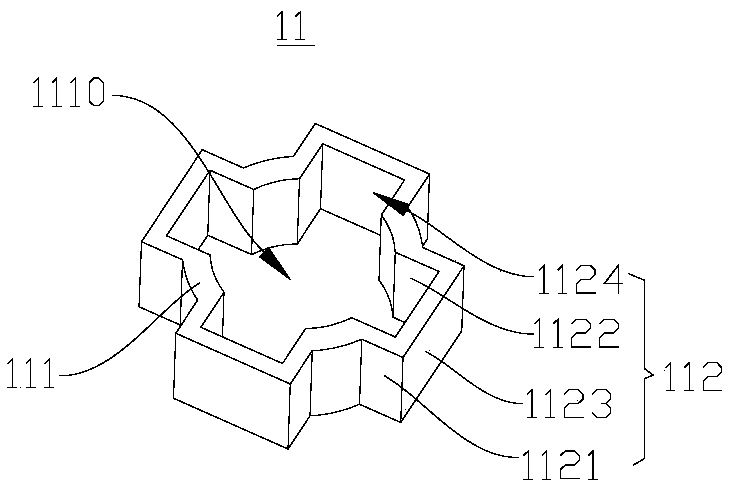

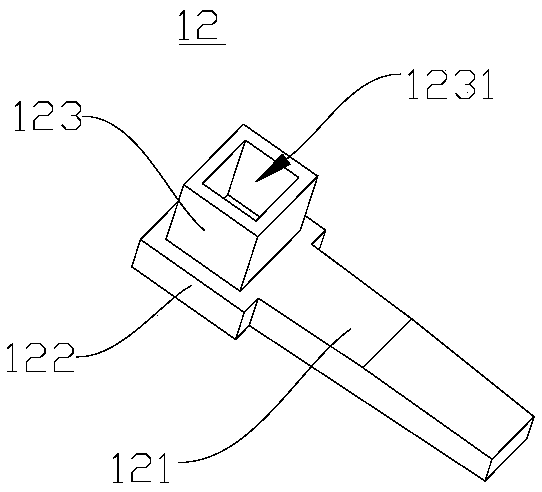

[0047] The first square tube scaffold joint 01 includes a joint 11 and a plug connector 12 . see figure 2 , the connector 11 includes a positioning portion 111 and a pluggin...

no. 2 example

[0055] see Figure 5 , this embodiment provides the second square tube scaffolding 200 . The second-type square-pipe scaffold 200 includes the second-type square-pipe scaffold joint 05 , the column 02 and the second-type square pipe 06 . The second-type square tube scaffold joints 05 are arranged on the columns 02 , and the second-type square tube scaffold joints 05 are connected through the second-type square tubes 06 . Multiple square tube scaffolds 200 of the second type are connected to each other to form the entire scaffolding project.

[0056] Next, the specific structure of each component of the second square tube scaffold 200 will be introduced in detail.

[0057] see Figure 6 , the second square tube scaffold joint 05 includes a positioning portion 111 and an overlapping portion 51 . A positioning hole 1110 is defined on the positioning portion 111 . The column 02 is connected to the positioning portion 111 through the positioning hole 1110 . The positioning pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com