Wavy woven latticed shell structure and construction method thereof

A wave-shaped and reticulated shell technology, applied to building components, building structures, roofs, etc., can solve the problems of lack of architectural rhythm and aesthetic feeling, high technical requirements for welding workers, and low material utilization efficiency, so as to reduce the possibility of instability The effect of simple and simple form of joints, increasing aesthetics and ornamental

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

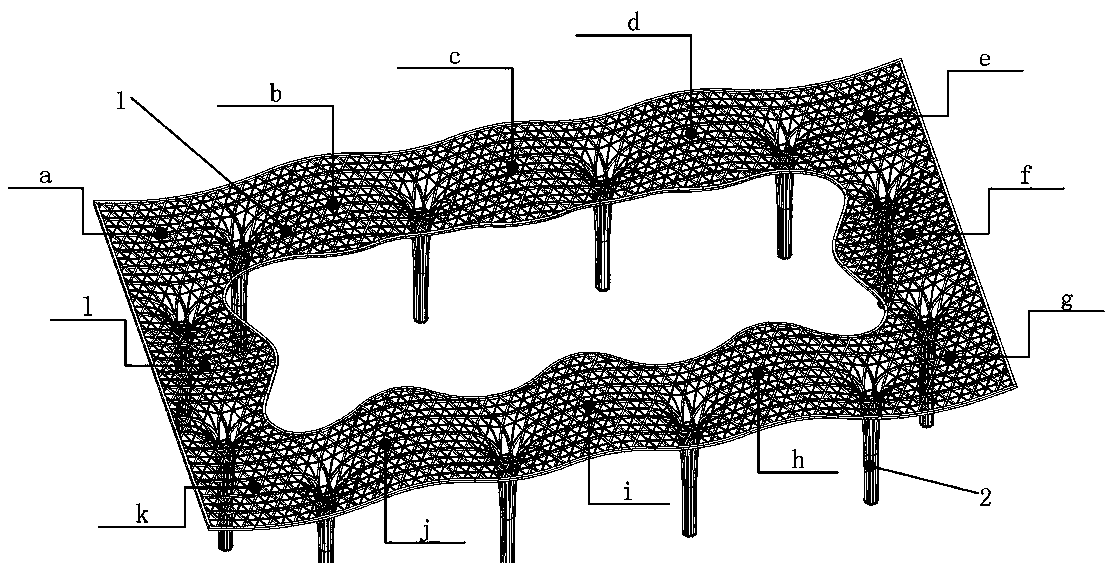

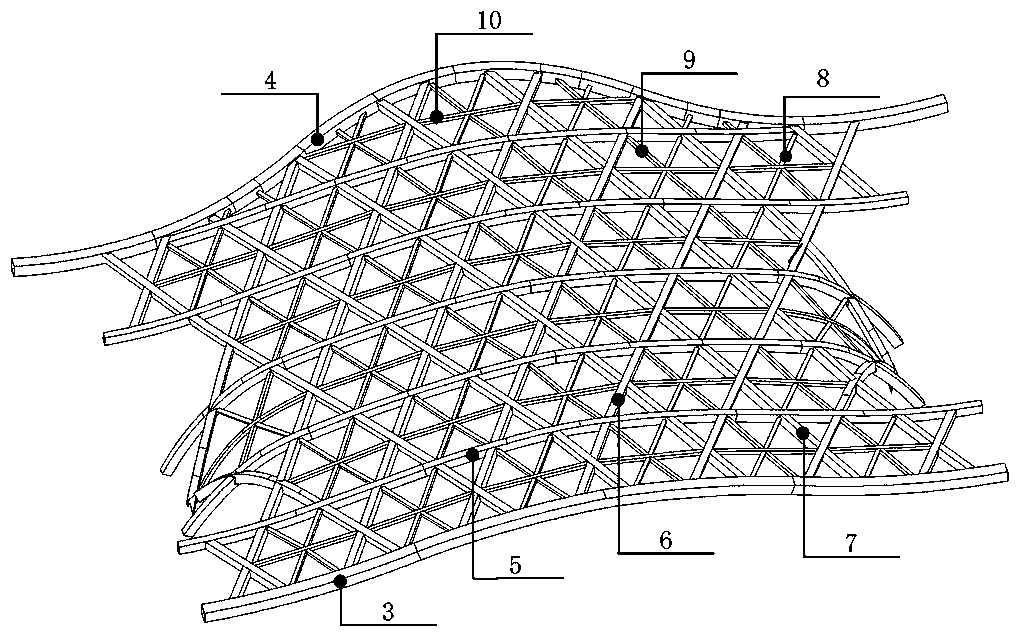

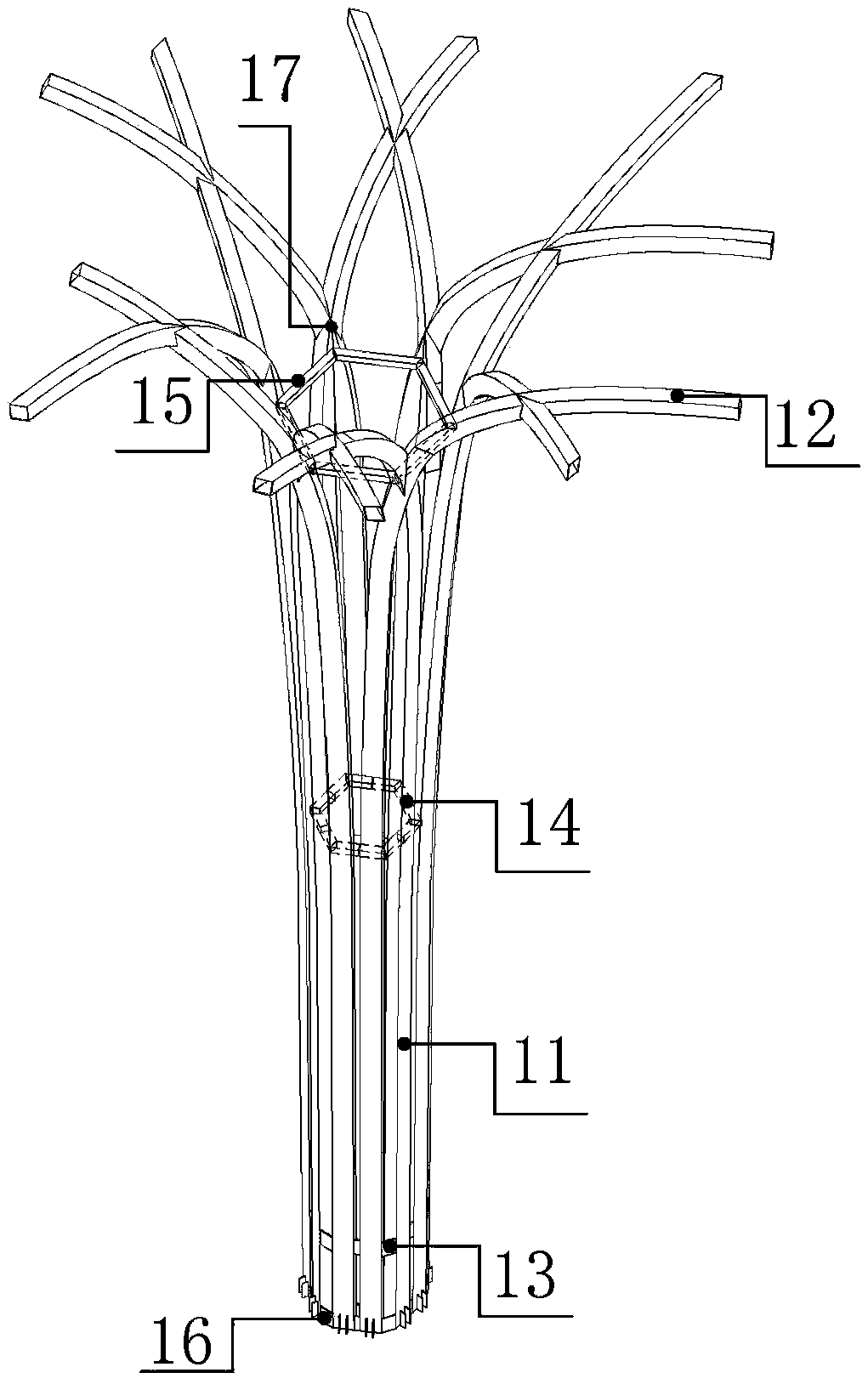

[0026] see figure 1 and figure 2 As shown, a wave-shaped braided reticulated shell structure, the reticulated shell 1 is a wave-shaped frame structure, including wavy longitudinal main rods 5 distributed in parallel and at intervals and oblique main rods cross-connected with the longitudinal main rods 5 6 and the secondary oblique main rod 7; the tree-like column 2 is connected below the trough position of the reticulated shell 1, and the reticulated shell 1 communicates with the inside of the tree-like column 2 at the trough position.

[0027] Further, the oblique main rods 6 and the secondary oblique main rods 7 are respectively arranged in parallel and at intervals, and the two cross each other to form a rhombus grid.

[0028] Further, the longitudinal main rod 5 passes through the midpoint of the adjacent sides of the rhombus grid, and divides the rhombus grid into regular hexagonal grids in the middle and triangular grids at both ends.

[0029] Further, the reticulated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com