Cup assembly and food high-speed blender

A cooking machine and component technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of large workload of the drive device, increased cup thickness, low crushing efficiency, etc., to improve processing efficiency, reduce contact distance, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

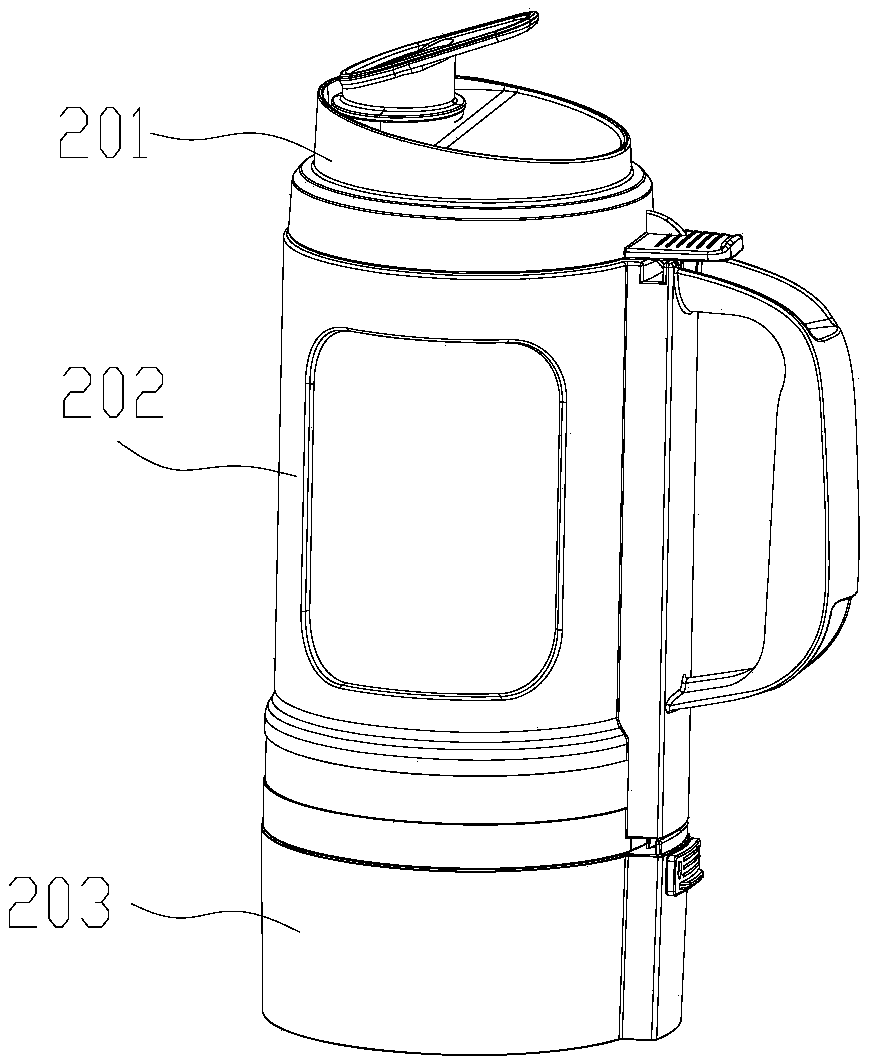

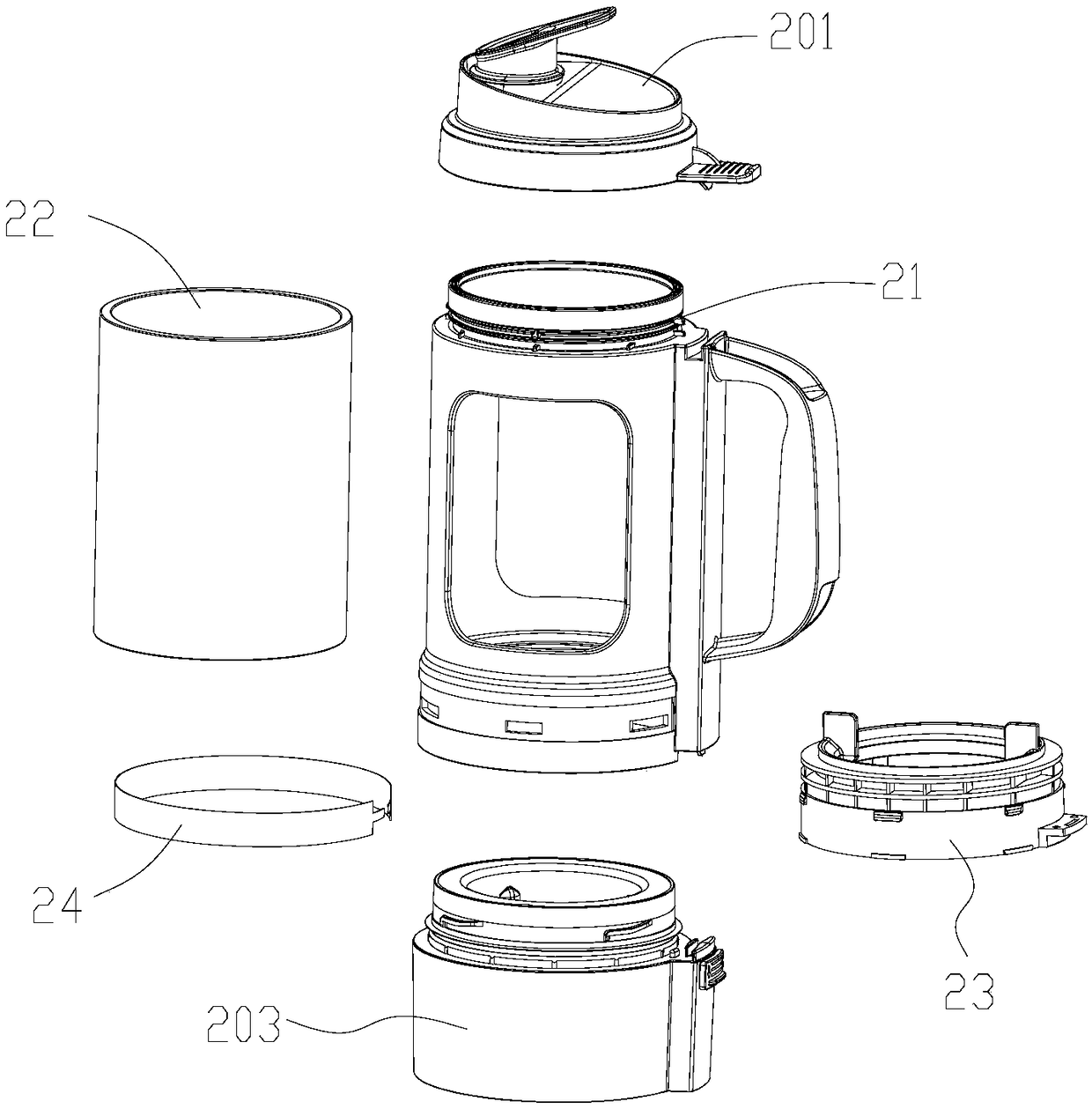

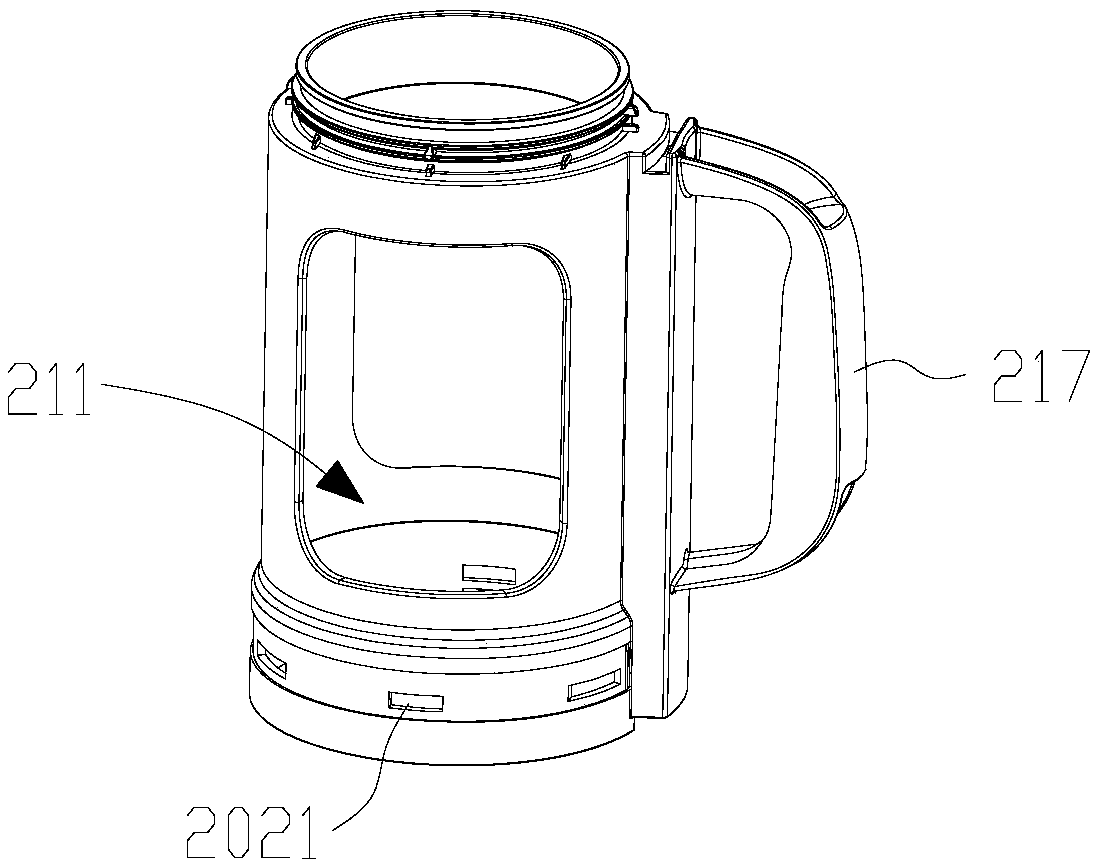

[0046] see Figure 1 to Figure 18 , the cup assembly 2, which includes a lid 201, a cup body 202 and a cup holder 203, the cup holder 203 is sealed and connected to the lower end of the cup body 202, the lid 201 is installed on the upper end of the cup body 202 for opening and closing the inner cavity of the cup body 202, and the cup holder 203 is provided with a cutter assembly 204 and a heating device 205, the cup holder 203 is provided with a stirring chamber 2031 passing through the inner cavity of the cup body 202, and the side wall of the stirring chamber 2031 is provided with a number of vertical first spoiler ribs 2032, the cutter assembly 204 is installed in the stirring chamber 2031.

[0047] Compared with the prior art, the cup assembly 2 provided by the present invention can reduce the contact distance between the cutter assembly 204 and food by setting the stirring chamber 2031 in the stirring chamber 2031, which can effectively improve the processing efficiency a...

Embodiment 2

[0090] see Figure 23 The main difference between this embodiment and Embodiment 1 is that the glass inner cup 22 is a double-layer glass, which includes a first cup body 221 on the outer layer and a second cup body 222 on the inner layer. The second cup body 222 is provided with a second spoiler rib 223 arranged vertically, the first cup body 221 is a cylindrical structure, and the two ends of the first cup body 221 and the second cup body 222 are connected into one body through a welding process. By adopting the structure of double-layer glass, a layer of first cup body 221 is welded outside the second cup body 222, so that the glass inner cup 22 forms a cylindrical shape, so that there is no gap between the glass inner cup 22 and the cup shell when installed. The gap provides better protection for the glass inner cup, and solves the assembly requirements of the glass inner cup 22 and the cup shell 21 and the technical requirements for setting the second spoiler rib 223 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com