Cable conductor continuous stranding drawing forming device

A technology for cable conductors and forming devices, which is used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of cable conductors falling off, insufficient clamping force of cable conductors, and low twisting efficiency, etc., to increase the clamping force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

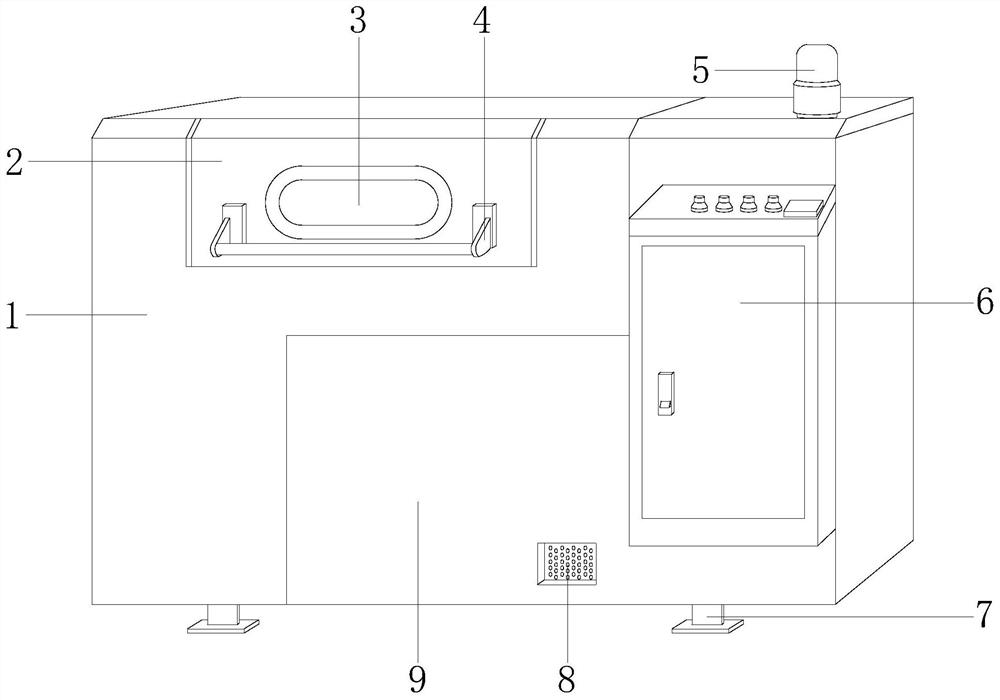

[0025] see Figure 1-Figure 4 , the present invention provides a continuous stranding and drawing forming device for cable conductors, the structure of which includes a stranding host 1, a box door 2, a viewing window 3, a handle 4, a warning light 5, an operating table 6, supporting feet 7, cooling holes 8, and a device base 9. A box door 2 is fixedly installed on the top of the twisted host 1, a window 3 is embedded in the front surface of the box door 2, a handle 4 is fixedly installed on the box door 2, and the window 3 is located directly above the handle 4, The warning light 5 is fixedly mounted on the top of the device base 9, the warning light 5 is electrically connected with the stranding host 1 through wires, the operating table 6 is fixedly installed on the device base 9, and the operating table 6 is connected with the twisting wire through the wires. The main unit 1 is electrically connected, the supporting feet 7 are fixedly welded to the bottom of the device base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com