Rod conveying line control method and device

A control method and technology of a control device, which can be applied to conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as system failure, complexity, and complex overall control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

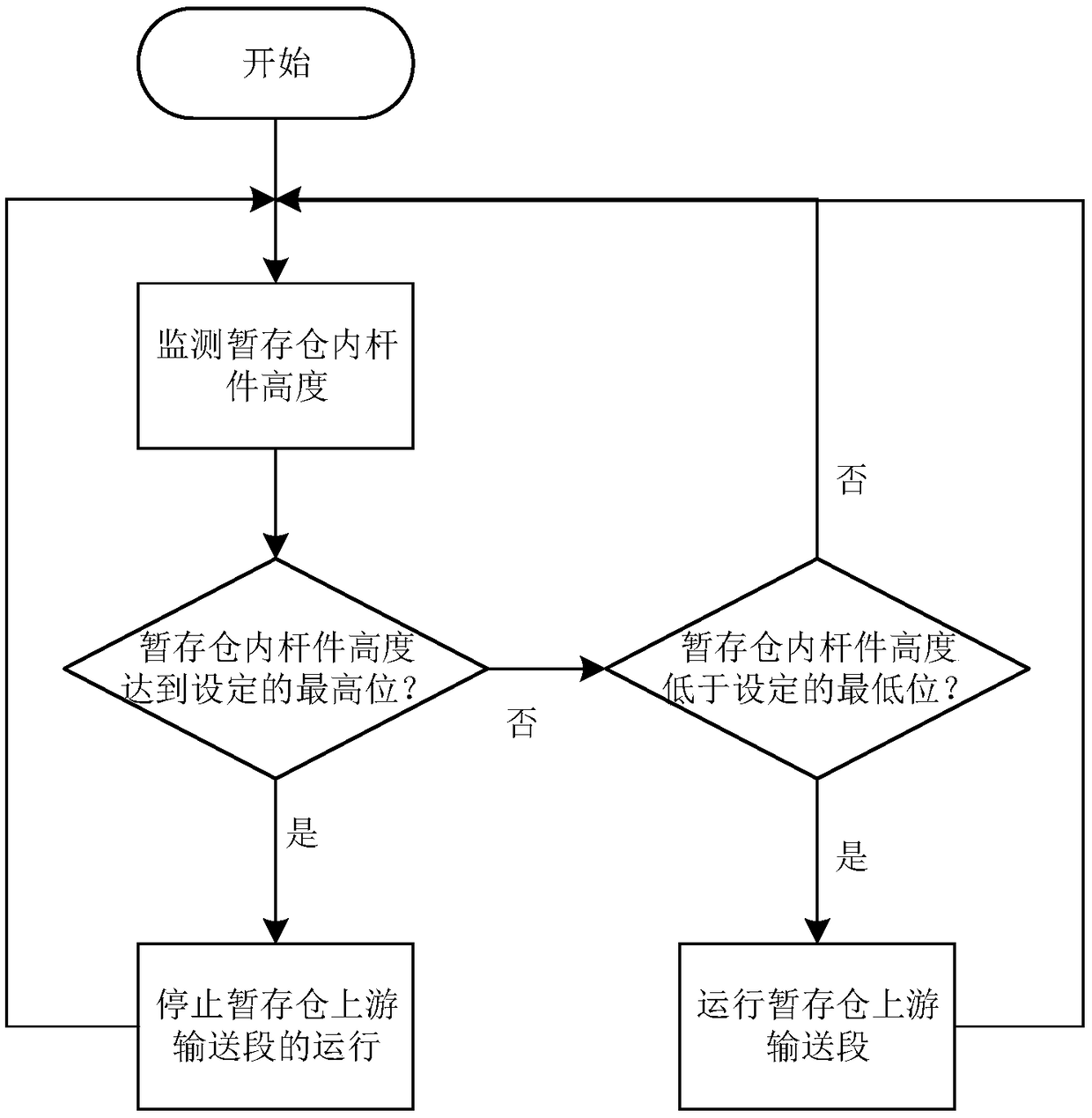

[0020] The invention provides a method for controlling a rod conveying line, such as figure 1 shown, including the following steps:

[0021] 1) Monitor the height of the rods in the temporary storage warehouse;

[0022] 2) If the height of the rods in the temporary storage warehouse reaches the set highest position, the operation of the upstream conveying section of the temporary storage warehouse will be stopped.

[0023] If the height of the rods in the temporary storage warehouse does not reach the set maximum position, the upstream conveying section of the temporary storage warehouse will run.

[0024] The height of the rods in the temporary storage can be detected by sensors such as height sensors and position sensors. By detecting the height of the rods in the temporary storage, the control of the upstream conveying section of the temporary storage can be realized, which makes the control of the conveying line simpler and more convenient. This kind of linkage control c...

Embodiment 2

[0026] The invention provides a method for controlling a rod conveying line, such as figure 2 As shown, on the basis of Embodiment 1 of the above method, when the height of the poles in the temporary storage warehouse does not reach the set highest level, it is also judged whether the height of the poles in the temporary storage warehouse is lower than a set minimum level, if , then run the upstream conveying section of the temporary storage warehouse.

[0027] Several rods in the temporary storage warehouse have just been taken away, and the upstream conveying section will send a corresponding number of rods into the temporary storage warehouse at the next moment. At this time, the upstream conveying section must be controlled to stop running. Stopping the upstream conveying section will easily reduce the life of the driving mechanism. Therefore, in order to avoid the above situation, through a set minimum position judgment, it is possible to avoid frequent start and stop of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com