Container cover and powdery granule container

A technology of container cover and cover base, applied in the field of packaging, can solve the problems of breaking the anti-theft ring, inconvenient operation of opening the anti-theft cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

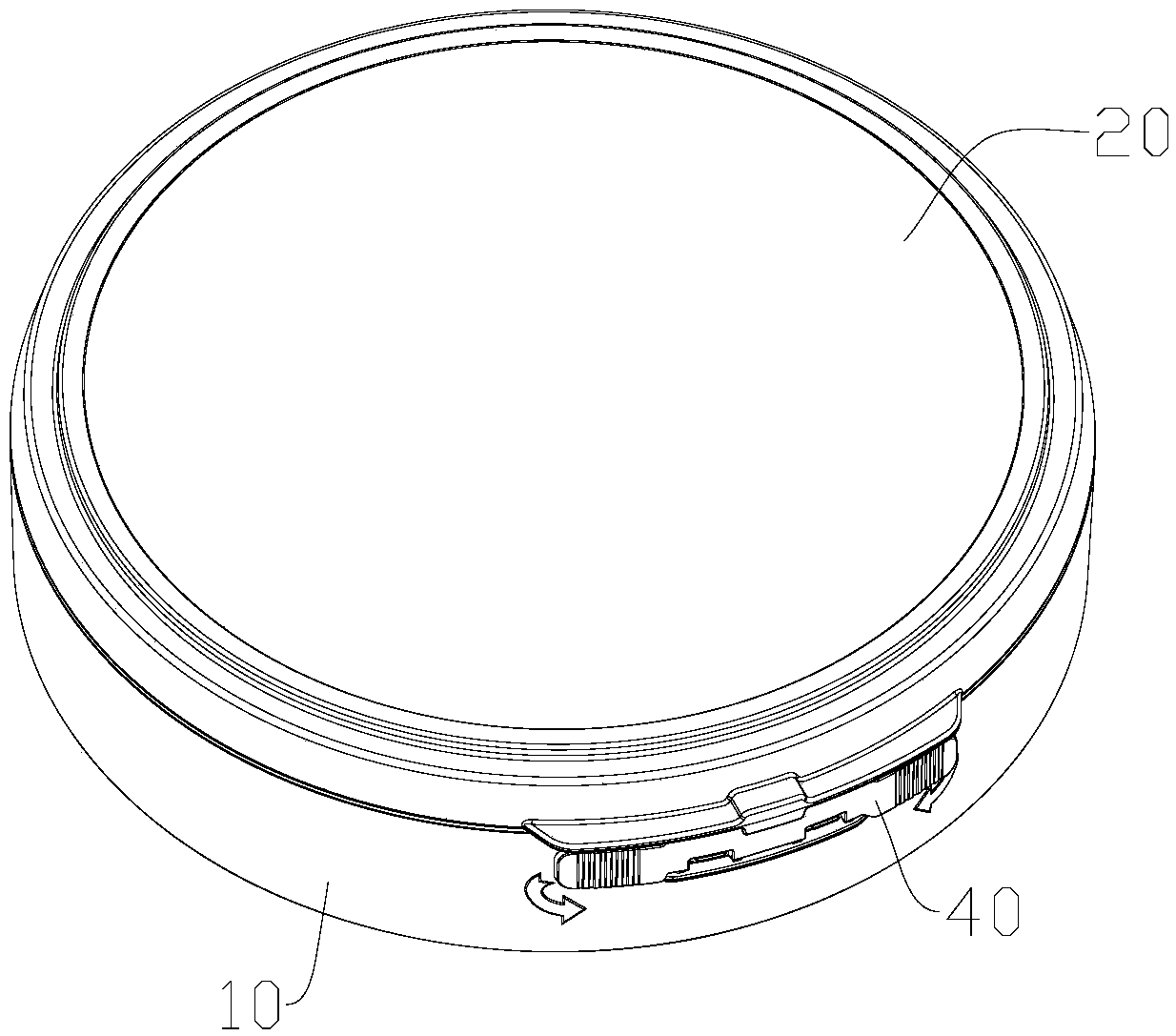

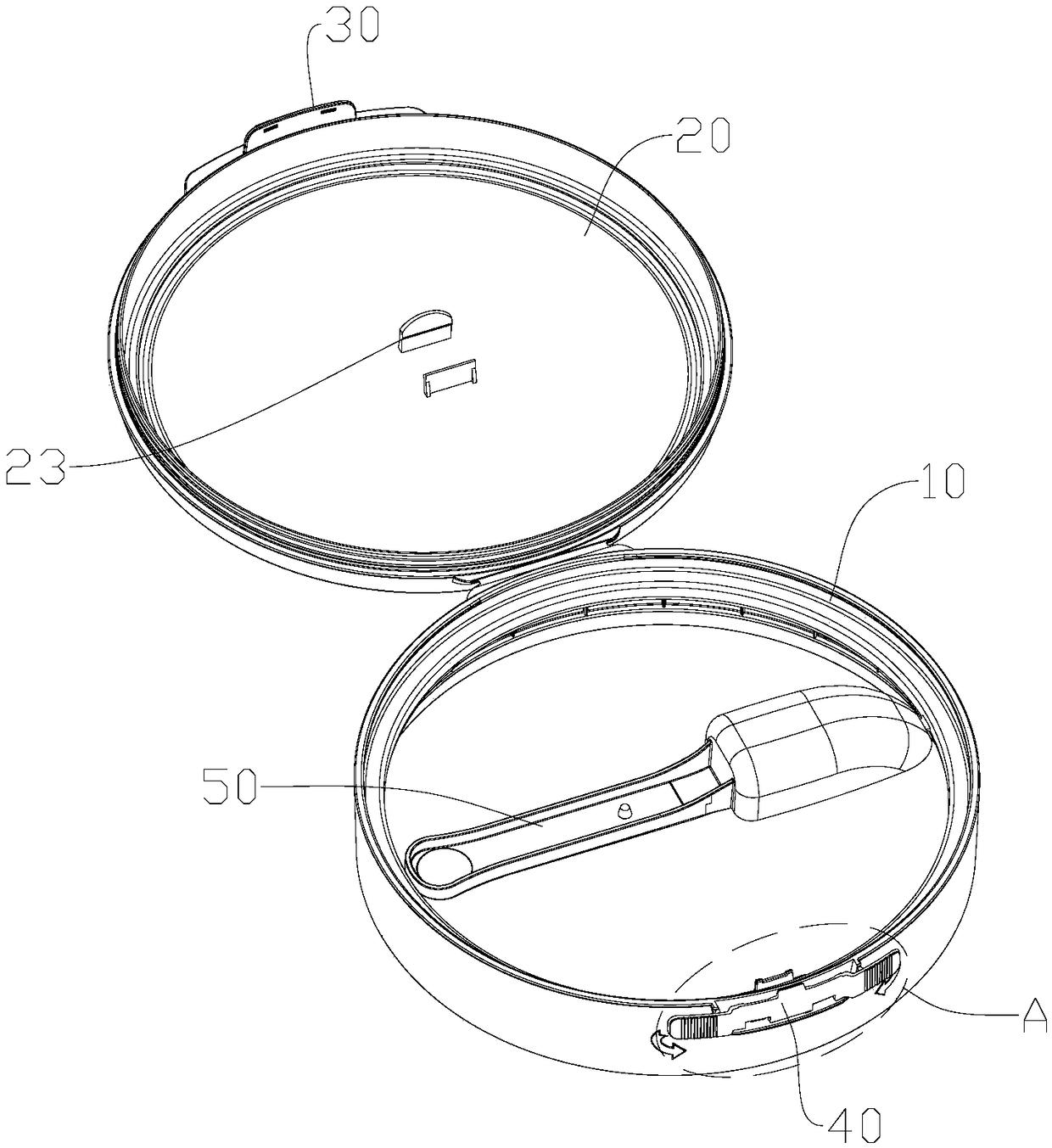

[0044] Please refer to Figure 1-16, a container cap provided in Embodiment 1 of the present invention is used for sealing the tank body. The container cap includes a cover seat 10 for connecting with the tank body and a cover body 20 for covering the mouth of the container tank. One side of the body 20 is rotatably connected with the cover base 10, and the other side of the cover body 20 is snapped connected with the cover base 10 through a locking structure. On the seat 10, an anti-theft piece 40 is used to compress the locking member 30 from the radially outer side of the cover body 20. The outer wall of the locking member 30 is provided with a first buckle portion, and the outer wall of the anti-theft sheet 40 is provided with a second buckle for connecting with the second locking part. The first buckle part snap fits with the second buckle part.

[0045] The lid body 20 of the container lid in the above-mentioned embodiment is snap-connected with the lid seat 10 through ...

Embodiment 2

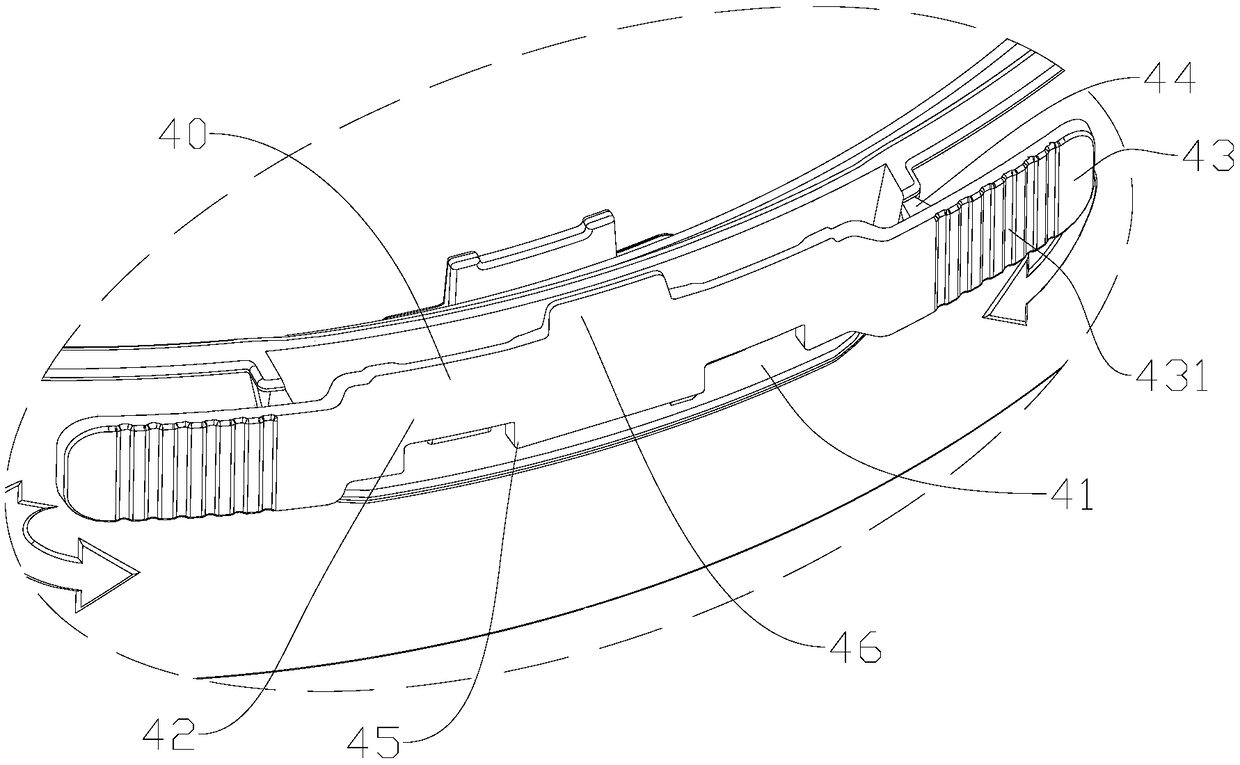

[0057] The difference between the container cap and the powdered granule container provided by the present embodiment and the first embodiment mainly lies in that the structure of the anti-theft sheet 40 is different, which is embodied in:

[0058] like Figure 9-Figure 16 As shown, the extension direction defining the thickness of the cover base 10 is the second direction Y, and the anti-theft sheet 40 includes an anti-theft sheet body 42 that is connected to the outer wall of the cover seat 10 at both ends and deviates from the anti-theft sheet body 42 in the second direction Y. One side of the cover base 10 extends away from the anti-theft sheet body 42 and is spaced apart from the second free section 49 on the outer wall of the cover base 10 , and the through hole 41 is provided on the anti-theft sheet body 42 . The connection area between the anti-theft sheet 40 and the container cover is much smaller than that between the anti-theft ring and the container cover in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com