Apparatus and method for attaching / detaching circular arrayed fasteners

A technology of threaded fasteners and dismounting devices, which is applied in the direction of wheel assembly and disassembly equipment, vehicle parts, transportation and packaging, etc. It can solve the problems of wrench module cost, production time, and manpower consumption, so as to save manpower and facilitate movement and installation, improving production and labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

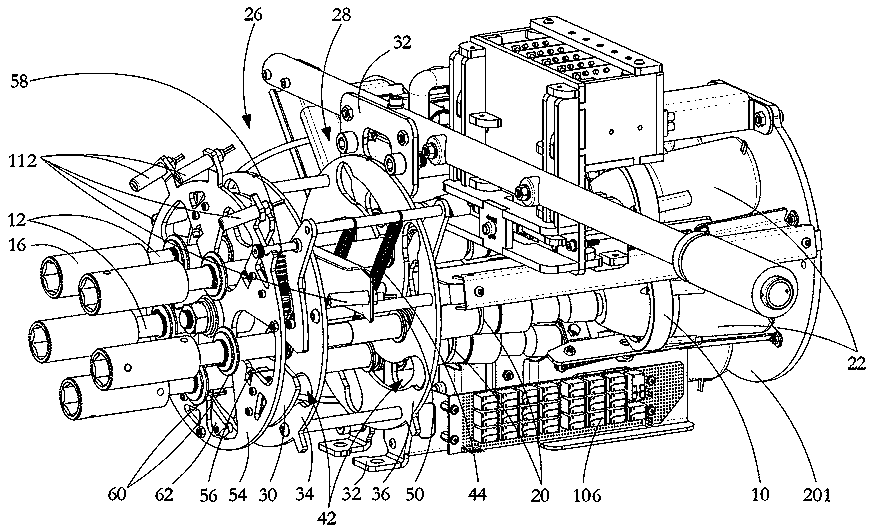

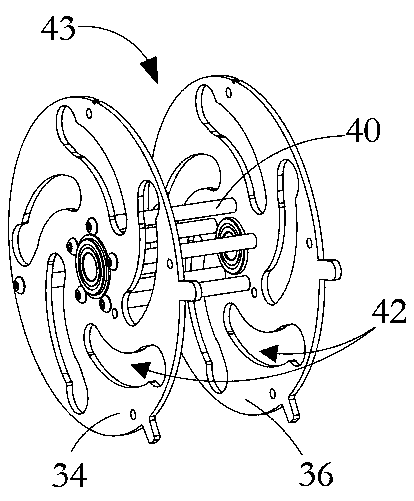

[0037]Before the detailed structure and operation process of this tool is described in detail, it is necessary to introduce the structure and parameters related to the wheel installation of the vehicle. The wheels on the vehicle are usually fixed to the wheel mounting base such as the outer flange of the hub bearing unit or similar parts by a plurality of threaded fasteners (hereinafter referred to as wheel fasteners or fasteners). The wheel is referred to as a first base member, and the above-mentioned wheel mounting base is referred to as a second base member or wheel mounting member. Wherein, the wheel fastener is composed of a first component and a second component that can form a thread pair. A first member of the fastener, such as a nut, is screwed into a second member of the fastener, such as a screw, secured to the wheel mounting base. The wheel is placed between the first member of the fastener and the wheel installation base, so that the wheel can be firmly pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com