Strip bending device for thermal power simulator

A technology of thermal simulation and bending device, which is applied in the direction of educational appliances, teaching models, instruments, etc., can solve the problems of inconvenient experimental work, lack of supporting equipment for thermal simulation experimental machines, thermal simulation strip bending experiments, etc., and achieve rapid adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

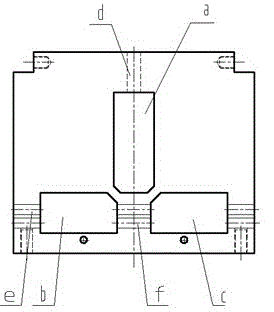

Image

Examples

Embodiment Construction

[0015] Cooperate the feeding device in the present invention with the dovetail groove on the gleeble thermal simulation experiment machine through the dovetail block 16, place the blank 15 in the trough on the blank clamp 22, and fasten the blank 15 by the screw 24 and the pressing plate 23 to send Between the upper and lower rollers in the frame, adjust the position of the left and right lower roller bearing seats through the size gaskets 9 and 7. Then manipulate the hydraulic cylinder to carry out the bending deformation experiment on the blank 15 through the front and rear depressing rods 5, 5', and carry out detection and research through the pressure sensors installed on the upper and lower roller bearing seats.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com